| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tube Accessories |

|---|---|

| Brand Name: | Lief Technology |

| Model Number: | 28AT-27 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1000 pcs |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10000 pcs Per Day |

| Delivery Time: | 7 days |

| Packaging Details: | Carton Box |

| Shape: | Square |

| Temper: | T3-T8 |

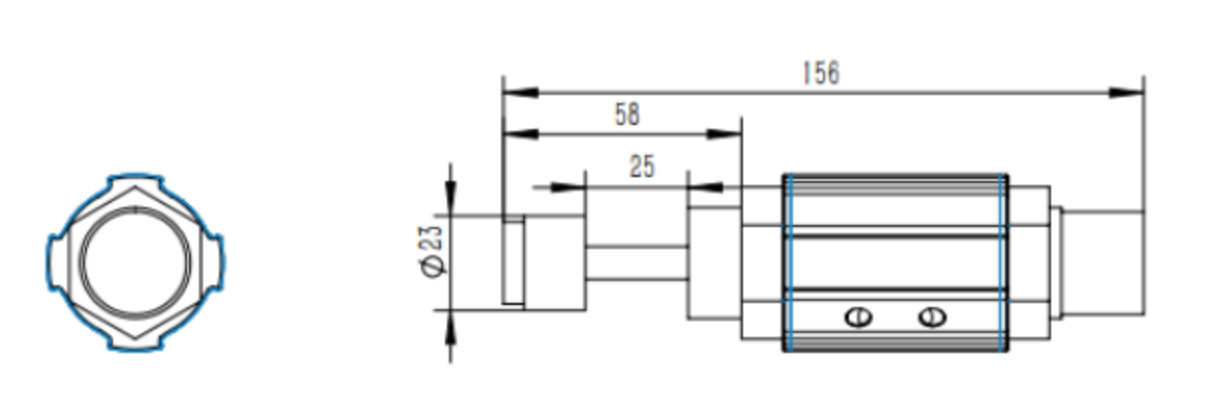

| Size: | For 28mm Aluminium Pipe |

| Color: | Silver |

| Tolerance: | ±1% |

| Weigt: | 0.4kg/pcs |

| Alloy or Not: | Is Alloy |

| Material: | 6063T5 aluminum alloy |

| Product Name: | Aluminium Pipe Connectors & Joints |

| Packing: | 50 pcs/box |

| Surface treatment: | Anodized |

| Application: | Manufacturer workshop, Automobile, Electronic, Assembling, logistic |

| Features: | High Durability, Corrorection Resistance, etc., |

| Company Info. |

| Lief Technology Company Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

1. We use international standard size, can be used in any

international standard parts.

2. Easy assembly, only needs a screwdriver to complete the

assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, and the overall system is

beautiful and reasonable after assembly.

4. Product diversification design, DIY customized production, can

meet the needs of different enterprises.

As the Lean products manufacturer, LiefTech adopts the world's most advanced automatic modeling, stamping system and precision CNC cutting system. The machine has automatic / semi-automatic multi gear production mode and the precision can reach 0.1mm. With the help of these machines, LiefTech can also handle various customer needs with ease. At present, LiefTech products have been exported to more than 15 countries.

We have a complete production chain, from material processing to warehousing delivery, are completed independently. The warehouse also uses a large space. LiefTech has a warehouse of 4000 square meters to ensure the smooth circulation of products.Moisture absorption and heat insulation are used in the delivery area to ensure the quality of the goods shipped.

|