| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Hardened Steel Bushings |

|---|---|

| Place of Origin: | Shandong, China |

| Brand Name: | sennai |

| Model Number: | 001 |

| Packaging Details: | Plastic packaging |

| Supply Ability: | 2000 Piece/Pieces per Day |

| MOQ: | 100 pieces |

| Price: | $0.60/pieces 100-499 pieces |

| Applicable Industries: | Construction works , Energy & Mining, Machinery Repair Shops, Manufacturing Plant, Other |

| Type: | bushing |

| Material: | Steel |

| Product name: | Bushing Sleeve |

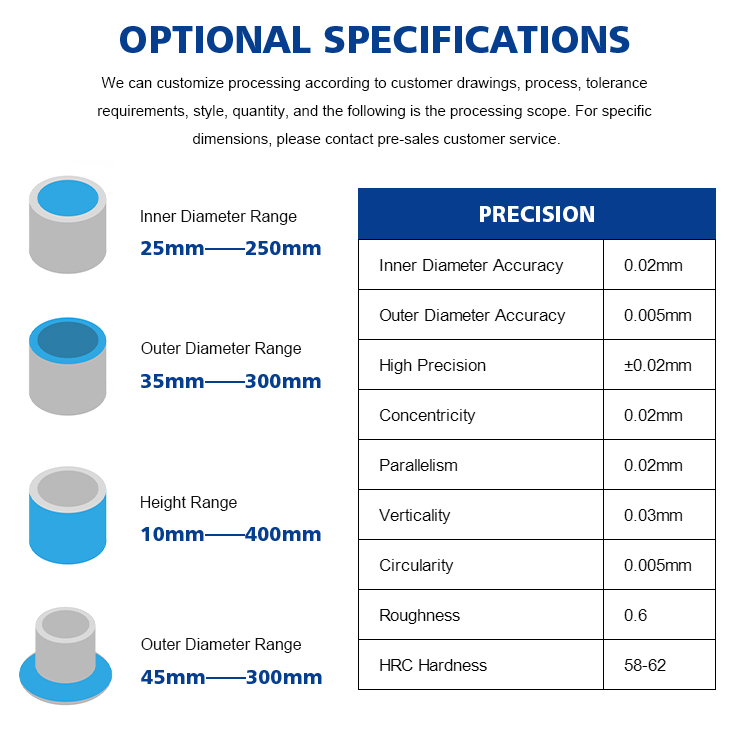

| Size: | Customized Size |

| Bush types: | Flange |

| Application: | Industrial Equipment |

| Features: | Wear Resistance |

| Lubricating: | Carbon |

| Product Material: | Steel+Porous Bronze+PTFE |

| Standard: | DIN1494 |

| Surface treatment: | Phosphating Black |

| Product Shape: | Customized Bushing |

| Company Info. |

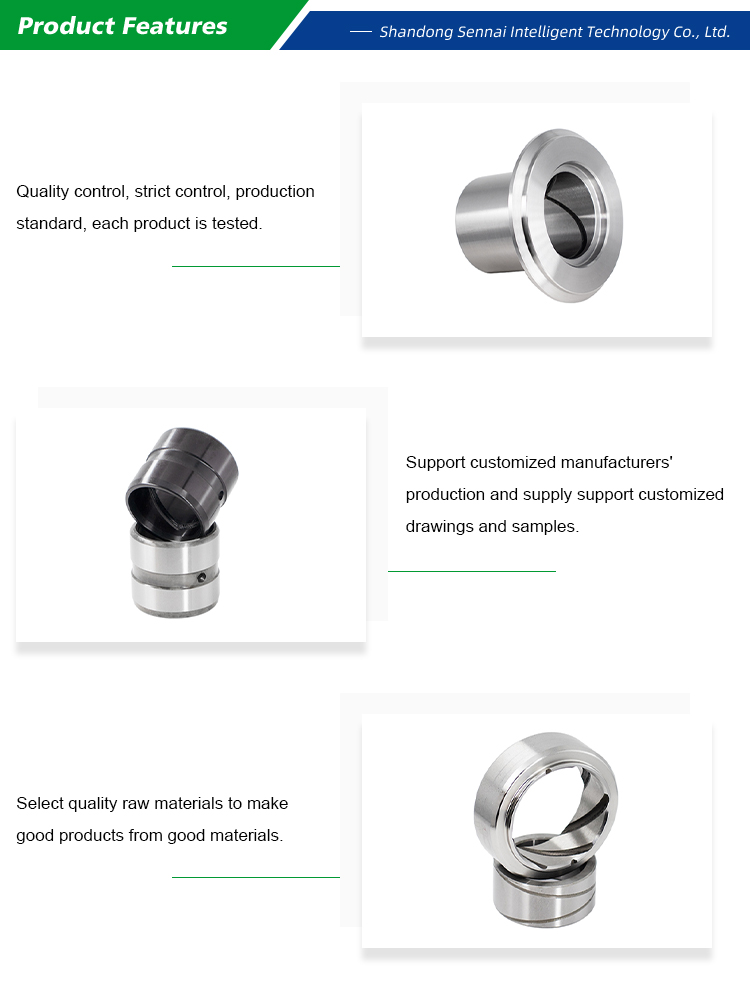

| Shandong Sennai Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Industrial Machinery Parts Oil Free Bushes Steel Bushes For Flanges

The advantages of using hardened steel bushings include:

Increased wear resistance: Hardened steel bushings have a higher hardness level, which makes them more resistant to wear, abrasion, and fatigue.

High load-bearing capacity: The strength of hardened steel allows the bushings to handle heavy loads and high levels of stress without deforming or breaking.

Corrosion resistance: Hardened steel bushings are typically coated or treated to resist corrosion, making them suitable for use in harsh or corrosive environments.

Dimensional stability: Hardened steel bushings maintain their shape and dimensions even under extreme conditions, ensuring a consistent fit and performance over time.

Cost-effective: Although more expensive than other types of bushings, hardened steel bushings have a longer service life and require less maintenance, making them cost-effective in the long run.

Overall, hardened steel bushings offer a reliable and durable solution for applications that require high strength, wear resistance, and load-bearing capacity.

Performance Index | Data | ||

Hardness | HRC | 58-62 | |

Max Load | N/mm2 | 250 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Performance Index | Data | ||

Hardness | HV | ≥650 | |

Max Load | N/mm2 | 200 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Performance Index | Data | ||

Hardness | HV | ≥650 | |

Max Load | N/mm2 | 200 | |

Max Linear Velocity | m/s | 0.1 | |

Max PV Value | N/mm2.m/s | 1.5 | |

WorkingTemperature Limit | ℃ | -100~ +350 | |

Linear Expension Coefficient | 10-5/℃ | 1.1 | |

Material and bushing characteristics | value | Company | value | ||

Maximum load | Mpa | 100 | psi | 145,00 | |

working temperature | ℃ | -40 to 300 | °F | -40 to 572 | |

Max Linear Velocity | m/s | 0.5 | fpm | 100 | |

Maximum PV Value | m/sxMPa | 1.65 | pis x fpm | 48,000 | |

Minimum hardness of sliding layer | HB | 210 | HB | 210 | |

Minimum hardness of dual parts | HRC | 40 | HRC | 40 | |

|