| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Shutter Door Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-SD |

| Certification: | CCC, SGS, ISO9001, CE |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets per month |

| Delivery Time: | 60days |

| Packaging Details: | Standard packing |

| Material thickness: | 1.3-1.5mm Galvanized steel |

| Line speed: | 3-5m/min with punching time |

| Forming Station: | 16 stations |

| Roller material: | Gcr15 high grade steel |

| Cutting way: | Hydraulic post cutting |

| Roller Material: | 45# steel |

| Usage: | Rolling door |

| Dimension(l*w*h): | 7000mm*1100mm*1200mm |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

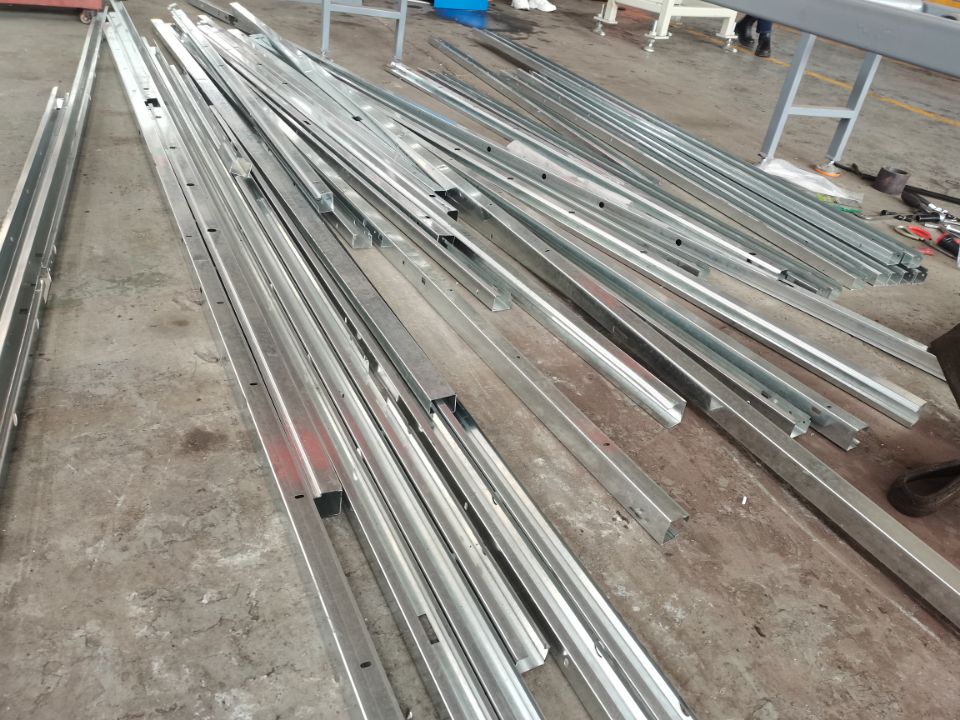

1.3-1.5mm TGalvanized Steel Coil Metal Roller Shutter Door Rail

Roll Forming Machine With Notch

We manufacture steel shutter door, steel garage door, door seaming machine, door packaging machine, door guide rail,rolling shutter door bottom machine,etc.

The completed production line is with components of Decoiler, Hydraulic punching to make notch hole, Roll forming machine,hydraulic cutting system, Electrial control system and out put tables.

Our Shutter door roll forming machines have made and exported to many oversea countries,like America, Chile, Combolia, Nicaragua,Algeria,South Africa,etc.

Shutter Door Machine Technical parameter

| Items | Specifications | |

| Material of coil | Material Thickness | 1.3mm-1.5mm galvanized coils |

| De-coiler | Weight | 3 tons automatic |

| Forming system | Rolling Speed | About 3-5 m/min(including punching and cutting time) |

| Roller Stations | About 16 stations forming | |

| Roller Material | Gcr15 steel with quenching | |

| Shaft Material | 45# Steel Diameter 75mm shaft | |

| Main Motor Power | 7.5 kw | |

| Hydraulic punching motor | 4Kw | |

Cutting system | Method of cutting | Saw cutting |

| Tolerance | +-1.5mm | |

| Electrical control system | Electric Source | 220V, 60HZ,3 phase or customized |

| Control System | PLC with touch screen | |

| Weight | About 5 tons | |

| Way Of Drive | Chain | |

| Size of machine | About Length 7500mm* Width 800mm* Height 1200m |

Shutter Door Machine Main Components

| Name | Quantity (set) |

| 3T Automatic De-coiler | 1 set |

| Hydraulic punching device | 1 set |

| Feeding with guide | 1 set |

| Main roll forming machine | 1 set |

| Run out tables | 2 sets |

| Control box | 1 set |

Rolling Shutter Door Machine Working Flow

De-coiler—→feeding with guide—→main roll forming machine—→hydraulic

cutting&punching —→ run out table

Advantage for our roller shutter

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Rolling Shutter Door Machine Profile Drawing

Packing & Delivery

Before loading to the container, we will check the machine first

Second, make some protection on the machine, Such as, we will paint

the coil on the roller and shaft, in case the roller and shaft got

corrosion and rusty during long time delivery

Third, we will make the plastic package on the easy damage parts,

and fix all the parts into container by the steel wire ropes, and

ensure the machine will not damage when shaking on sea.

At last, we will take photos for customer when loading to container

|