| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Automatic Welding Carriage |

|---|---|

| Brand Name: | HYZONT |

| Model Number: | KA-H10 |

| Certification: | CCC |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 500-1000 |

| Payment Terms: | L/C |

| Supply Ability: | 500 sets per month |

| Delivery Time: | 5-7 days |

| Packaging Details: | Carton |

| Material: | Aluminum Alloy |

| Power Supply: | AC220V |

| Product Name: | Automatic flange to plate MIG/MAG welding tractor |

| Service: | Excellent |

| Size: | 275*140*240 |

| Structure: | Compact |

| Warranty: | 1 Year |

| Weight: | Light |

| Welding Accuracy: | High |

| Welding Method: | Automatic |

| Welding Range: | Flange to plate welding |

| Welding Speed: | 100∼1000mm/min |

| Company Info. |

| Hyzont(Shanghai) Industrial Technologies Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Automatic flange to plate MIG/MAG welding tractor auto matic welding carriage welding tractor

Flat flange automatic welding trolleys are widely used in

industries such as ships, bridges, locomotives, steel structures,

and petrochemicals. Its main advantages include:

1. Reduce labor intensity and improve working environment

2. Improve work efficiency by 1.5 times that of manual welding

3. To avoid poor weld quality caused by human factors, the defect

rate of manual operation is generally around 20%, while using

automatic welding trolleys does not result in welding defects.

Therefore, its comprehensive benefits are improved by nearly 200%

compared to manual welding

4. High degree of automation to ensure the stability of welding

quality

5. No need for highly skilled technical workers

Features:

1. The I-type welding trolley is an automatic welding device

suitable for horizontal flange plate circumferential fillet

welding.

2. Small size and light weight, easy to move and install, and

unskilled workers can also perform welding

Specification

| Type | Contents | Note | |

| Trolly | power | AC 220V | |

| Size | 275*140*240 | W×L×H | |

| Weight | 15Kg | ||

| Moving | double wheels | ||

| Moving speed | 100-1000mm/min | ||

| Swing motor | DC24V 18RPM | option | |

welding gun | up/down | 100mm | |

| forward/back | 100mm | ||

| angle | 360° | ||

| Moving angle | 0° | ||

| Control | Swing speed | 0-10RPM | |

| Swing angle | 0-±10° | ||

| Swing time | 0-2S | ||

| Center moving | 0-±8° | ||

| Moving Speed | 100∼1000mm/min | ||

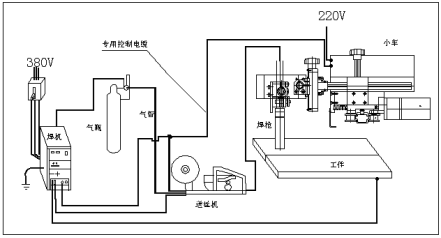

Connection of the machine

Install

(1) Installation conditions:

1. The necessary tools for welding are the welding power supply and wire feeder device;

2. Welding power supply (AC 220V) for walking and control of KA-C1;

3. CO2 gas tank for welding;

4. Direct welding gun for CO2 automatic welding;

5. Basic tools for other necessary tasks;

(2) System connection method

1. Install the track, which must ensure that the welding direction of the trolley is parallel to the weld seam

2. Install the trolley and use the installation handle to clamp the track wheels of the trolley onto the track

3. Install welding wire on the wire feeder and pull it to the end of the welding gun

4. Connect the welding gun port to the wire feeder

5. Connect the control power cable to the 8P port on the control panel of the car

6. Connect the control power cable to AC 220

|