| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Linear Bottle Blowing Machine |

|---|---|

| Brand Name: | Eceng |

| Model Number: | Q4500 |

| Certification: | CE SGS ISO |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1set |

| Supply Ability: | 10 Set/Sets per Month |

| Delivery Time: | 35days |

| Packaging Details: | Film pack |

| Blow Moulding Type: | Stretch Blow Moulding, Extrusion Blow Moulding |

| Voltage: | Three phase 380V |

| Dimension(L*W*H): | 2.6*1.8*2.45(m) |

| PLC Brand: | XINJE |

| Automation: | Automatic |

| Showroom Location: | Saudi Arabia, Spain, Turkey, France, Italy, Mexico, Pakistan, Viet Nam, Canada, United States, Brazil, United Kingdom, Indonesia, Germany, Egypt, Philippines, South Korea, Algeria, Chile, UAE, Japan, Uzbekistan, Nigeria, Argentina, Australia, Ukraine, Kyrg |

| Model type: | eceng company make blowing machine |

| Port: | Shanghai |

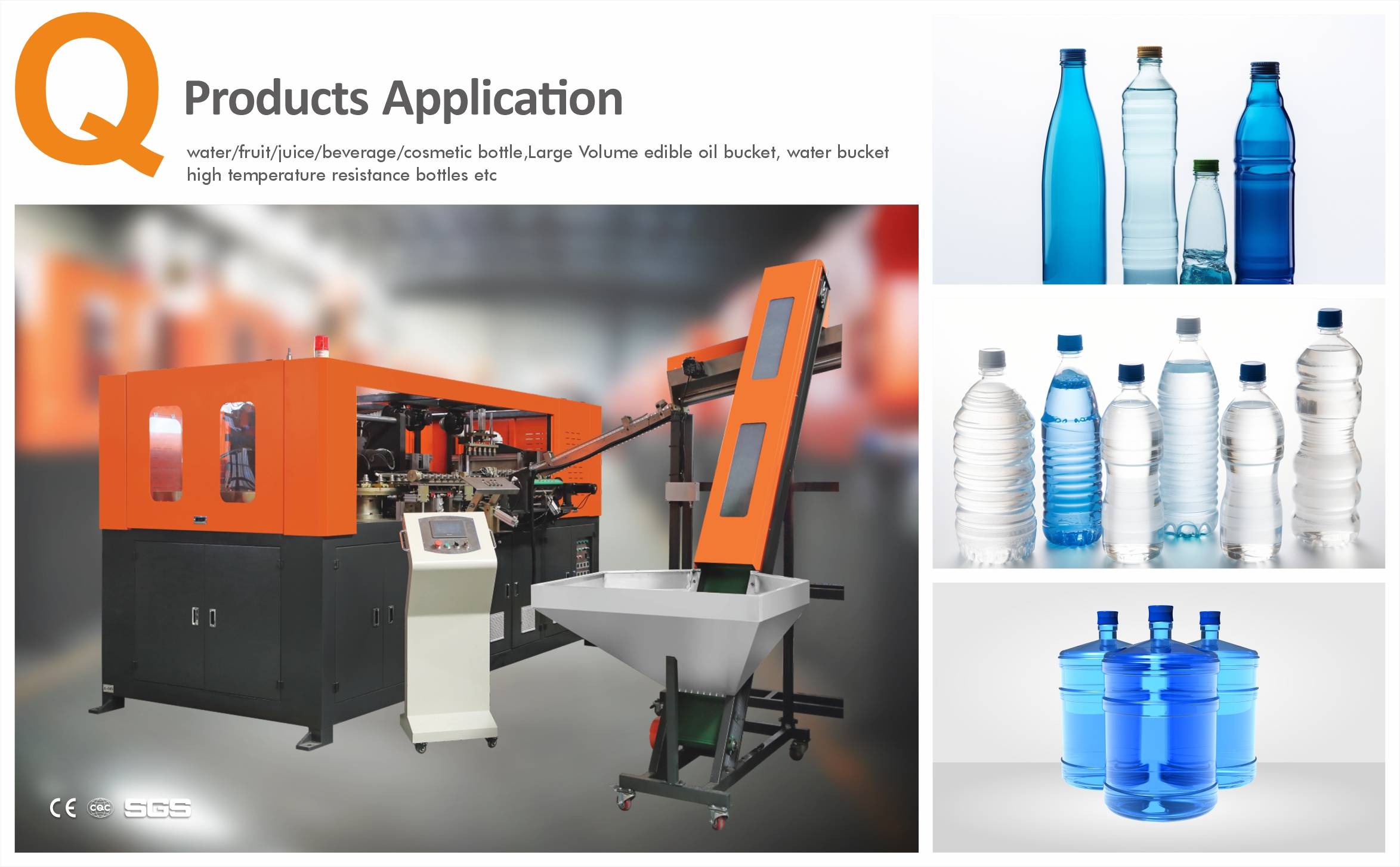

Automatic PET Bottle Blow Molding Machine 3 Cavity 4500BPH 0.5L-2L

Q linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type. Q series linear bottle blowing machine features: 1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system. 2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety. 3. suitable for flexible production of quantity and various bottle shape,wide range of applications,meet customer needs. 4. manual and automatic methods of operation, human-machine interface control, simple operation. 5. servo transmission system, high positioning accuracy, fast speed stability and good reliability. 6. less than 0.2% scrap rate for finished bottle .

| Item | Q4500 | |

| Bottle type specification | Cavity | 3 |

| Max.volume | 2000ML | |

| Bottle mouth maximum overall DIdiameter | 38mm | |

| Bottle biggest diameter | 105mm | |

| Bottle maximum height | 330mm | |

| Production specification | Theoretical output | 4500BPH |

| Bottle type capacity | 500ML | |

| Bottle type weight | 17g | |

| Bottle type | circular | |

| Power specifications | Light tube quantity | 18pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 24KW | |

| All electric machine installation | 27KW | |

| Actual consumption | 19KW | |

| Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1000L/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 1500Ltr/min | |

| Forzen water specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10℃ | |

| Consumption | 5000kcal/hr | |

| Forzen water flow | 30L/min | |

| Machine specification | Size of the machine | 2.6x1.8x2.45 |

| Weight of the machine | 2.5ton | |

In today's world, where it's all about convenience, automatic

machines have made our lives much easier. One such 4500BPH 0.5L-2L Automatic PET bottle blow blowing mold molding

machine Eceng Q4500. This machine is designed to automate the

process of PET bottle blowing and molding, and its efficiency is

unmatched.

With its advanced technology, the machine produces high-quality

bottles that are suitable for use in various industries, including

food and beverage, healthcare, and beauty products. The 3 Cavity

4500BPH 0.5L-2L Automatic PET bottle blow blowing mold molding

machine has a unique ability to create PET bottles of different

shapes and sizes without compromising quality.

This machine comes with a 3-cavity mold system that allows it to

produce a maximum of 4500 bottles per hour. Additionally, it is

capable of creating bottles ranging from 0.5L to 2L. This makes the

machine highly versatile and suitable for small to medium-sized

businesses that require consistent production of bottles.

The 3 Cavity 4500BPH 0.5L-2L Automatic PET bottle blow blowing mold

molding machine works by blowing preheated PET material into a

bottle shape based on the design specifications programmed into the

machine's software. The machine then molds the bottle to ensure it

meets the desired shape and size.

One of the benefits of using this machine is its ability to

minimize waste by producing uniform bottles. The machine ensures

that the bottles produced have the same proportions, which

eliminates the need for overproduction and reduces material waste.

Another advantage of this machine is its low operational cost. The

machine has an automated system that requires minimal supervision

to operate, which reduces labor costs. Additionally, its

energy-efficient system significantly reduces power consumption,

resulting in lower electricity bills.

In conclusion, Q4500 3 Cavity 4500BPH 0.5L-2L Automatic PET bottle

blow blowing mold molding machine is an advanced automated machine

that can boost a small to medium-sized business's operations. With

its excellent productivity and high-quality output, this machine is

an excellent investment that can improve the efficiency and

profitability of any business.

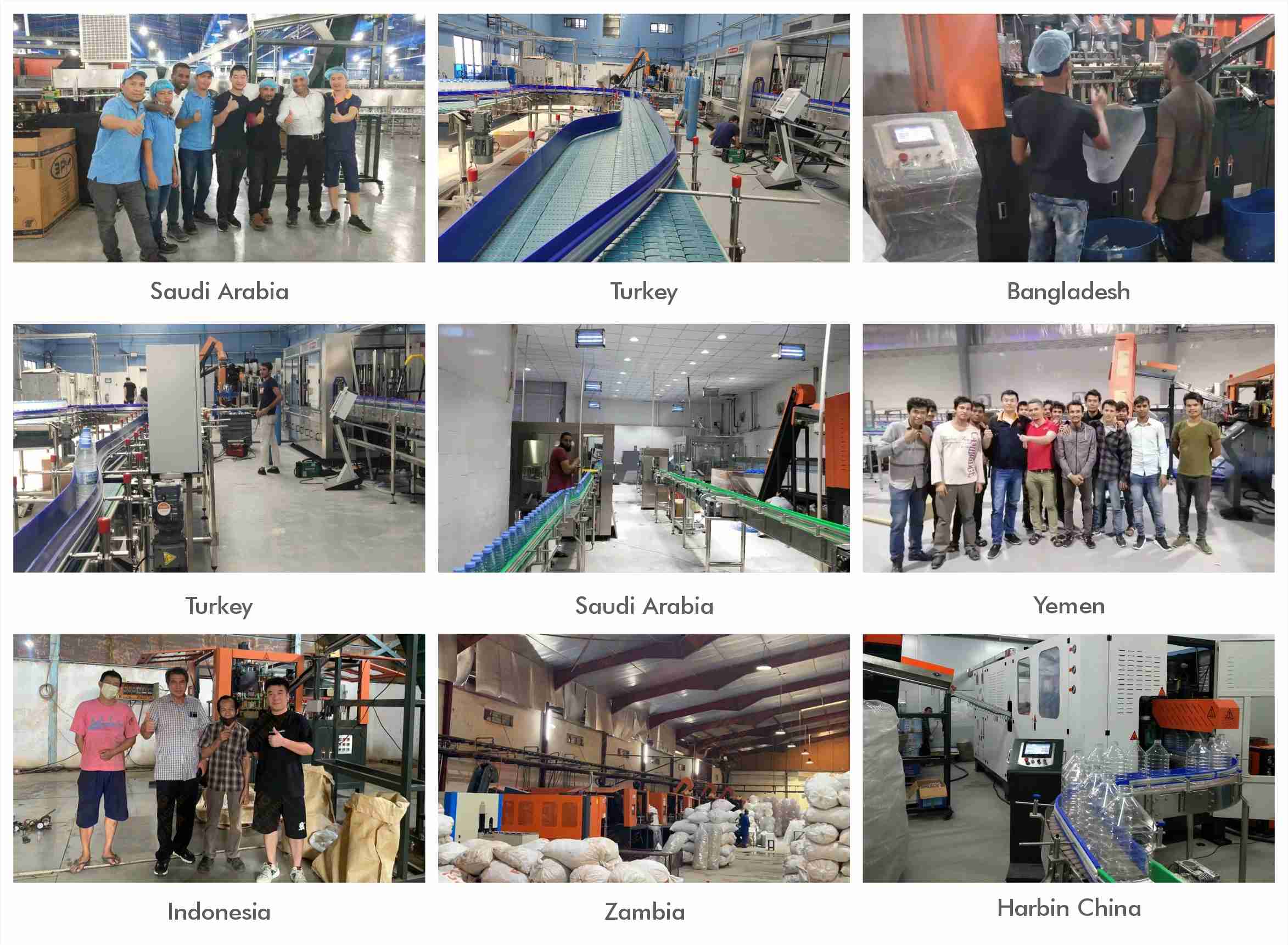

Zhangjiagang Eceng Machinery Co., Ltd is founded in 2007,We

manufacture fully-automatic PET bottle blowing machine, injection

mold,blowing mold etc.,suitable for 5ml-50L plastic bottles,water

bottles,carbonated beverage bottles,oil bottles,cosmetics

bottles.We can equip machine from 1-12 cavity,output from hundreds

bottles to 36,000 bottles/hour,also provide full set of production

system from preform production,bottle blowing,filling to final

packaging.

So far Eceng machinery have provided more than 2050 sets machines

for more than 170 countries in the world.Our equipments are highly

estimated by the clients, and are well known at home and abroad.We

sincerely hope to establish business relationship with friends all

over the world.

our advantage:1. Resonable price;2. Good after service;3. experienced skilled workers and professional engineers;4. Good quality ,excellent service ,long life mould;5. on time delivery time;6.our engineers can be online for 24 hours to serve you.

Normally the inner package, we will packed by the stretch film. Outer package we will use the export woodencase. Mostly we deliver the goods by sea as the freight is most reasonable in this way.

Q:Your company is a trading company or a direct factory?

A:We are a direct factory which locates in Zhangjiagang city.

Q:All of your products are made by yourself or compacted via purchasing the others?

A:We have independent technical team who focus on making machines,all the products are made by our technical team.

Q:What is the ability of your factory?

A:About 80 lines per year.

Q:Do you have any other services about your products?

A:We have a lot of experience on making projects and specifications for our clients,also we have a fixed service system.

Q:How do you make the quotation for clients?

A:The price depends on quality and performance but the clients should be satisfied first.

|