| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Slurry Pump Parts |

|---|---|

| Brand Name: | CNSME |

| Model Number: | 6/4D- 6/4E- E4147 |

| Certification: | ISO/CE |

| Place of Origin: | CHINA |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 300000 Sets per Month |

| Delivery Time: | 7 Working Days |

| Packaging Details: | Plywood Crate |

| Material: | Rubber |

| Shaft: | Horizontal Type |

| Flowrate: | 100-400m3/h |

| Head: | 10-80 m |

| Speed: | 800-1800r/ min |

| Max. Efficiency: | 70% |

Black Soft Natural Rubber Lined Spare Parts Slurry Pump Components Rubber Liners Impellers

1. Introduction:

Interchangeable rubber slurry pump parts can be used on Warman Series Pumps.

We supply interchangeable slurry pump parts, both metal and rubber lined. The rubber material we used has superior resistance to all other materials in fine particle slurry applications. The antioxidants and anti degradents used in our material have been optimized to improve storage life and reduce degradation during use. The high erosion resistance is provided by the combination of its high resilience, high tensile strength and low shore hardness.

Slurry pumps are made for high wearing and heavy duty and high corrosion slurry applications. Our pumps and replacement parts are used worldwide industries like mining, mineral processing, power generation, aggregate processing, or any type of slurry pumping application. We specialise in handling the toughest and most abrasive applications and have taken this to a new level with the SH (equivalent to Warman ) series.

| Formula | Rubber Type | Shore Hardness | Tensile Strength | Elongation | Impact Elasticity | Proportion | Characteristics |

| Natural Rubber | 50±3 | 24 | 500 | 70 | 1.07 | Tear Resistance | |

| S42 | Neoprene | 50±3 | 11 | 450 | 1.3 | High Temp. Proof | |

| U01 | Polyurethane | 80±3 | 30 | 500 | 1.2 | High Wear Resistant |

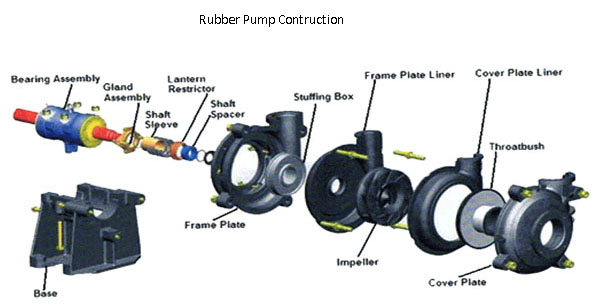

Components:

Impeller

The impeller, either elastomer, stainless steel or high-chrome

material, is the main rotating component which normally has vanes

to impart the centrifugal force to the liquid.

Casing

Split outer casing halves of cast contain the wear liners and

provide high operation pressure capabilities. The casing shape is

generally of semi-volute or concentric, efficiencies of which are

less than that of the volute type.

Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection

and vibration. Heavy-duty roller bearing are housed in a removable

bearing cartridge.

Shaft sleeve

A hardened, heavy-duty corrosion-resistant sleeve with O-ring seals

at both ends protects the shaft. A split fit allows the sleeve

removed or installed quickly.

Shaft Seal

Expeller drive seal, Packing seal, Mechanical seal.

Drive Type

V-belt drive, gear reducer drive, fluid coupling drive, and

frequency conversion drive devices.

2.Construction of Rubber Lined Slurry Pumps:

3.Specifications:

| Slurry Pump SH Series Metal Slurry Pump Specifications | ||||||||||||

| Pump Model | S×D (inch) | Allowable Max. Power (kw) | Material | Clear Water Performance | Impeller | Pricing | ||||||

| Capacity Q | Head H(m) | Speed n(r/min) | Max.Eff. η% | NPSH (m) | No. of Vanes | Vane Dia. (mm) | Weight (kg) | |||||

| Impeller | m3/h | l/s | ||||||||||

| SH/25B | 1.5×1 | 15 | Metal (A05) | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2-4 | 5 | 152 | 91 |

| SH/40B | 2×1.5 | 15 | 32.4-72 | 9-20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 184 | 118 | ||

| SH/50C | 3×2 | 30 | 39.6-86.4 | 11-24 | 12-64 | 1300-2700 | 55 | 4-6 | 214 | 191 | ||

| SH/75C | 4×3 | 30 | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4-6 | 245 | 263 | ||

| SH/75D | 4×3 | 60 | 245 | 363 | ||||||||

| SH/100D | 6×4 | 60 | 162-360 | 45-100 | 12-56 | 800-1550 | 65 | 5-8 | 365 | 626 | ||

| SH/100E | 6×4 | 120 | 365 | 728 | ||||||||

| SH/150E | 8×6 | 120 | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 510 | 1473 | ||

| SH/150F | 8×6 | 260 | 510 | 1496 | ||||||||

| SH/150R | 8×6 | 300 | 510 | 1655 | ||||||||

| SH/200F | 10×8 | 260 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3193 | ||

| SH/200ST | 10×8 | 560 | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 686 | 3750 | ||

| SH/250F | 12×10 | 260 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 3760 | ||

| SH/250ST | 12×10 | 560 | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 762 | 4318 | ||

| SH/300ST | 14×12 | 560 | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-10 | 965 | 6409 | ||

| SH/350TU | 16×14 | 1200 | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 | 10000 | ||

4.Typical Applications:

Ash Handling

Cyclone Feeds

Pulp and Paper

Abrasive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Slurry Pump Being Used :

|