| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Inconel Alloy |

|---|---|

| Brand Name: | DLX |

| Model Number: | Inconel 718 bar |

| Certification: | CE,ROHS |

| Place of Origin: | China Jiangsu |

| MOQ: | 5 |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 500 tons per month |

| Delivery Time: | 7-50 days |

| Packaging Details: | Spool package with Carton box, Coil package with polybag |

| Material: | Ni Cr Fe |

| Nickel(Min): | 50% |

| Magnetic Permeability: | 1.0011 |

| Curie Temperature: | -112 °C |

| Density: | 8.19 |

| CTE, linear 20°C: | 13 µm/m-°C |

| Condition: | Hard / Soft |

| Sureface: | Bright,Oxided |

| Tensile Strength: | 760-1600MPA |

| Melting Point: | 1260 - 1336℃ |

| Specific Heat Capacity: | 0.435 J/g-°C |

| Thermal Conductivity: | 11.4 W/m-K |

| Elongation: | 25 % |

| Company Info. |

| Changzhou DLX Alloy Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Inconel Alloy 718 is a precipitation hardenable nickel-based alloy designed to display exceptionally high yield, tensile and creep-rupture properties at temperatures up to 1300°F. The sluggish age-hardening response of alloy 718 permits annealing and welding without spontaneous hardening during heating and cooling. This alloy has excellent weldability when compared to the nickel-base superalloys hardened by aluminum and titanium. This alloy has been used for jet engine and high-speed airframe parts such as wheels, buckets, spacers, and high temperature bolts and fasteners.

| Element | Limiting Chemical Composition (%) |

| Nickel (plus Cobalt) | 50%-55% |

| Chromium | 17%-21% |

| Niobium (plus Tantalum) | 4.75%-5.50% |

| Molybdenum | 2.80%-3.30% |

| Titanium | 0.65%-1.15% |

| Aluminum | 0.20%-0.80% |

| Cobalt | 1% max |

| Carbon | 0.08% max |

| Manganese | 0.35% max |

| Silicon | 0.35% max |

| Phosphorus | 0.015% max |

| Sulfur | 0.015% max |

| Boron | 0.006% max |

| Copper | 0.30% max |

| Iron | Balance* |

The applications of Inconel 718 round bars include:

Type we could offer

| AMS Number | Alloy | Type | UNS | Cross Ref. Spec | Misc./Shape | |

|---|---|---|---|---|---|---|

| AMS 5590 | Inconel 718 | Nickel | N07718 | - | Tubing |  |

| AMS 5596 Foil | Inconel 718 | Nickel | N07718 | - | Foil |  |

| AMS 5596 Plate | Inconel 718 | Nickel | N07718 | - | Plate |  |

| AMS 5596 Sheet | Inconel 718 | Nickel | N07718 | - | Sheet |  |

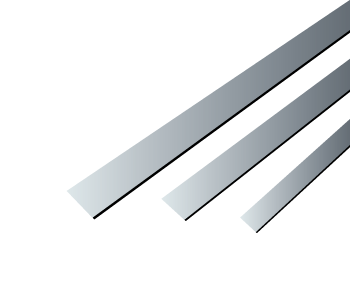

| AMS 5596 Strip | Inconel 718 | Nickel | N07718 | - | Strip |  |

| AMS 5597 Plate | Inconel 718 | Nickel | N07718 | - | Plate |  |

| AMS 5597 Sheet | Inconel 718 | Nickel | N07718 | - | Sheet |  |

| AMS 5597 Strip | Inconel 718 | Nickel | N07718 | - | Strip |  |

| AMS 5662 Bar | Inconel 718 | Nickel | N07718 | - | Bar |  |

| AMS 5662 Custom Tube | Inconel 718 | Nickel | N07718 | - | Custom Tube |  |

| AMS 5662 Ring | Inconel 718 | Nickel | N07718 | - | Ring |  |

| AMS 5663 Bar | Inconel 718 | Nickel | N07718 | - | Bar |  |

| AMS 5663 Custom Tube | Inconel 718 | Nickel | N07718 | - | Custom Tube |  |

| AMS 5663 Ring | Inconel 718 | Nickel | N07718 | - | Ring |  |

| AMS 5664 Bar | Inconel 718 | Nickel | N07718 | - | Bar |  |

| AMS 5664 Custom Tube | Inconel 718 | Nickel | N07718 | - | Custom Tube |  |

| AMS 5664 Ring | Inconel 718 | Nickel | N07718 | - | Ring |  |

| AMS 5832 | Inconel 718 | Nickel | N07718 | - | Wire |  |

| AMS 5962 Bar | Inconel 718 | Nickel | N07718 | - | Bar |  |

| AMS 5962 Wire | Inconel 718 | Nickel | N07718 | - | Wire |  |

|