| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Dropper Bottle Filling Machine |

|---|---|

| Model NO.: | FPL-12 Filling Machine |

| Automatic Grade: | Automatic |

| Material Type: | Liquid |

| Filling Valve Head: | Multi-Head |

| Feed Cylinder Structure: | Multi-Room Feeding |

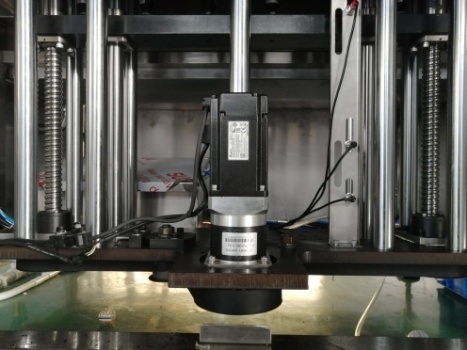

| Dosing Device: | Plunger |

| Filling Principle: | Pressure |

| Packaging Container Lifting Structure: | Chute Pneumatic Combination Lifting |

| Structure: | Linear |

| Packaging: | Bottle |

| Packaging Material: | Plastic |

| The Material: | Stainless Steel |

| Transport Package: | Packed in Wooden Cases |

| Specification: | 2000mmx1500mmx2200mm |

| Trademark: | Jinxing |

| Origin: | China Jiangsu |

| HS Code: | 8422301090 |

| Supply Ability: | 100 Units a Year |

| Shipping Cost: | To be negotiated| Freight Cost Calculator |

| After-sales Service: | Site Installation, Site Maintenance |

| Warranty: | 12 Months |

| Type: | Piston Filling Machine |

| Customization: | Available | Customized Request |

| Place of Origin: | China |

| Brand Name: | Jinxin |

| MOQ: | 1 |

| Price: | negotiable |

| Packaging Details: | carton box |

| Company Info. |

| Changzhou Jintan Jinxing Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

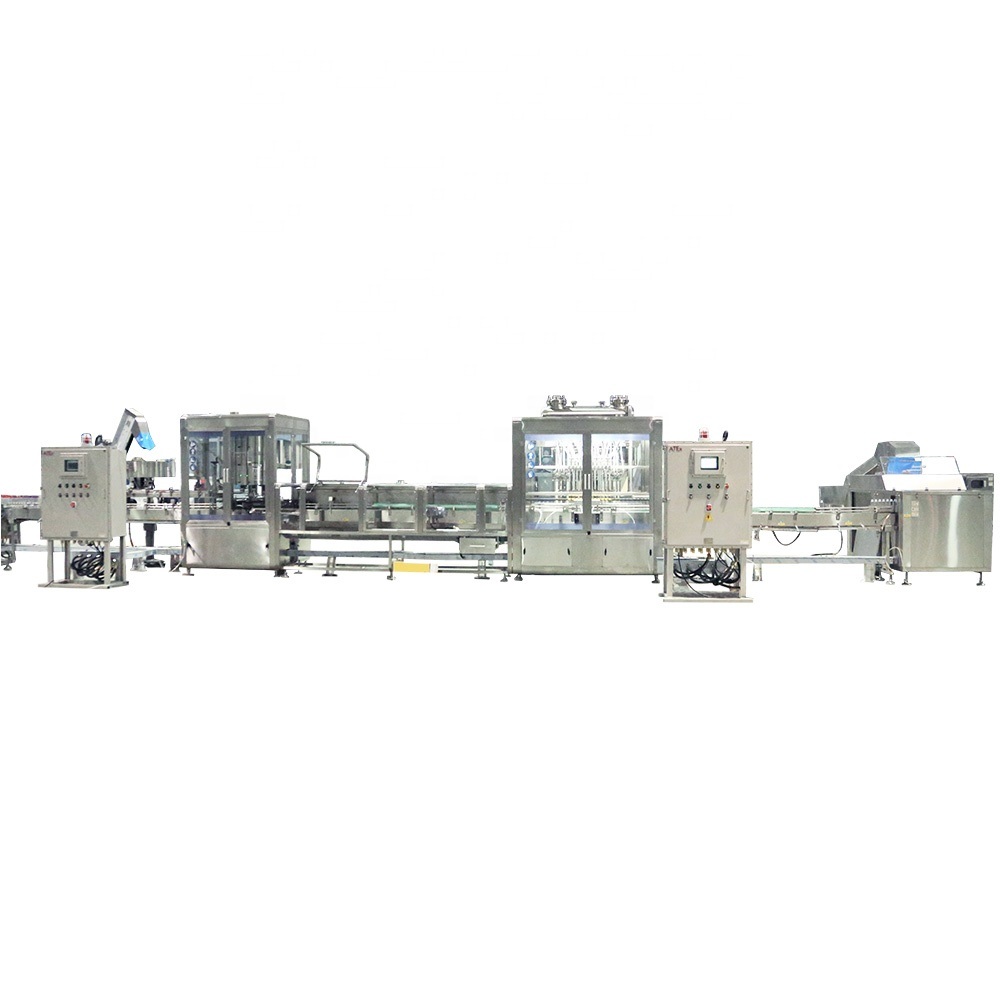

Essential oil products are becoming an indispensable health care product in life. They have the effects of pain relief and sleep aid. This kind of product is very popular in Europe and the United States. This machine is a tincture filling machine. It is sometimes referred to as a bulk liquid filler. The integral machine combines multiple packaging functions on the same machine. It is the core component of the liquid filling line and is sometimes called the "essential oil production line" because it fills the vial and then inserts the "dropper" bottle cap and the "screw" bottle cap. Dropper caps are important because consumers use "tinctures" by putting a few drops under the tongue. This route of administration avoids contact with the liver and ensures better absorption into the blood.

| Filling Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle | 16 Nozzle | 18 Nozzle |

| Filling Speed | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min | 80 bot/min | 90 bot/min |

| Filling Volume | 50-500ml, 100-1000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V,50/60Hz,2Phase;380V, 50/60Hz, 3 Phase | ||||||

| Air Consumption | 0.6-0.8Mpa | ||||||

| Remark | 1. Filling speed is 500ml/ bottle of water. 2. Filling speed will be different due to different material characteristics. 3. More options can be customized according to your requirements. | ||||||

|