| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Injection Epoxy Resin |

|---|---|

| Brand Name: | JT-RESIN |

| Model Number: | JT2252 |

| Certification: | SGS,CE,UL |

| Place of Origin: | China |

| MOQ: | 5000kg |

| Price: | $3/kg |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 200Ton/week |

| Delivery Time: | 5 days |

| Packaging Details: | DRUM |

| Usage: | casting insulation parts and high thermal shock resista |

| CAS No.:: | 1675-54-3 |

| MF:: | C21H24O4 |

| TG: | 100 |

| Adhesion Strength: | High |

| Appearance: | Transparent liquid |

| Chemical Resistance: | High |

| Compressive Strength: | High |

| Corrosion Resistance: | High |

| Curing Temperature: | Low |

| Curing Time: | Fast |

| Flexural Strength: | High |

| Heat Resistance: | High |

| Product Name: | Injection Epoxy Resin |

| Shear Strength: | High |

| Solid Content: | High |

| Tensile Strength: | High |

| Company Info. |

| jiangte insulation composite |

| Verified Supplier |

| View Contact Details |

| Product List |

Wholesale casting resin and liquid epoxy resin (NPEL_9225) and Electrical insulation epoxy resin for molds and transform

Indoor electrical insulation parts for medium and high voltage equipment ,such as switchgears and electrical components.Encapsulation of large metal parts.Recommended for application with long term stresses up to service temperature of 85℃.

Liquid ,hot-curing casting resin system with high glass transition temperature for producing casting insulation parts with excellent mechanical end-properties and very high thermal shock resistance.

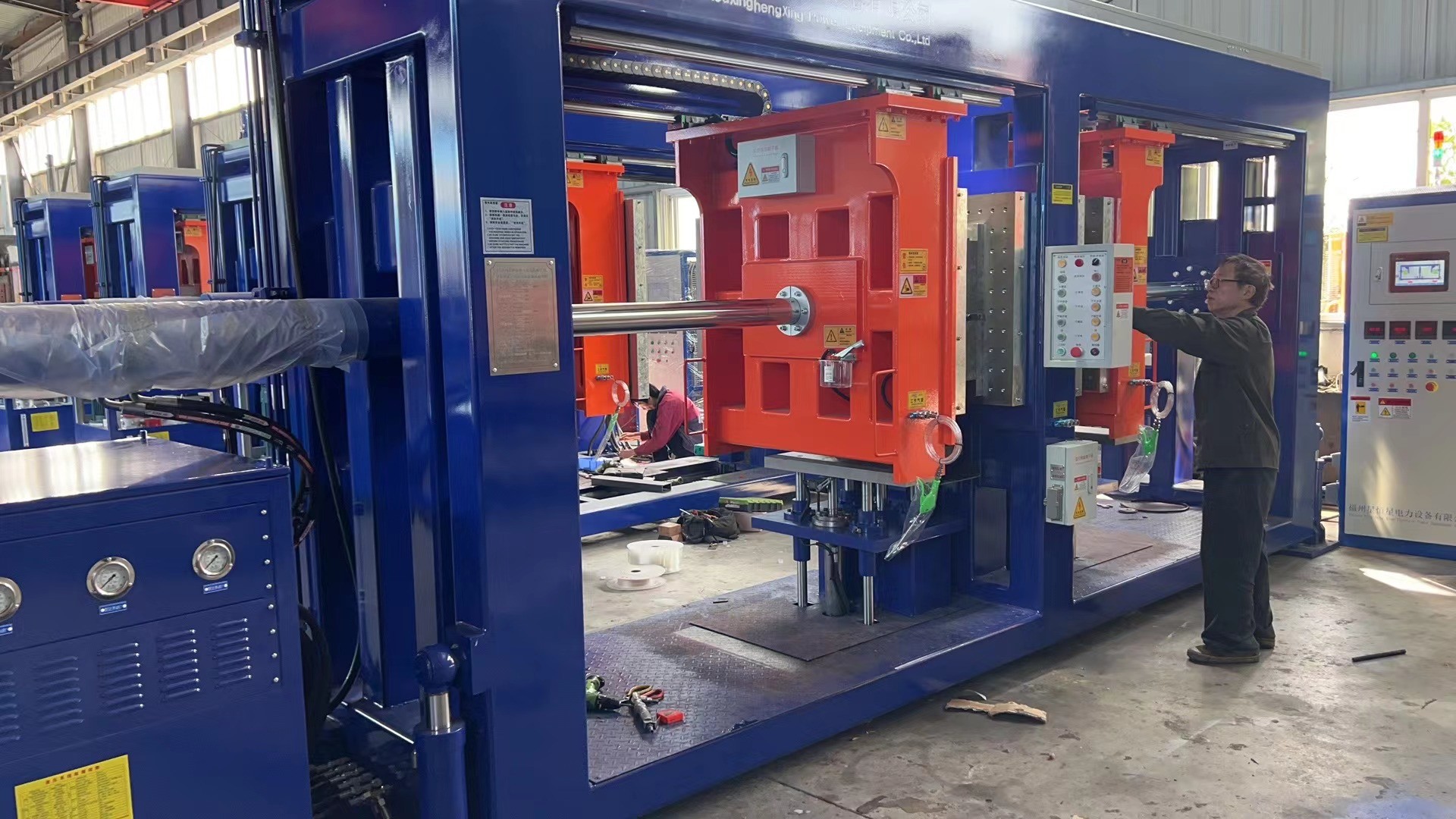

Vacuum casting process of instrument transformer

Resin model:

Resin/ Hardener / Silica powder = XXX : XXX : XXX (pbw)

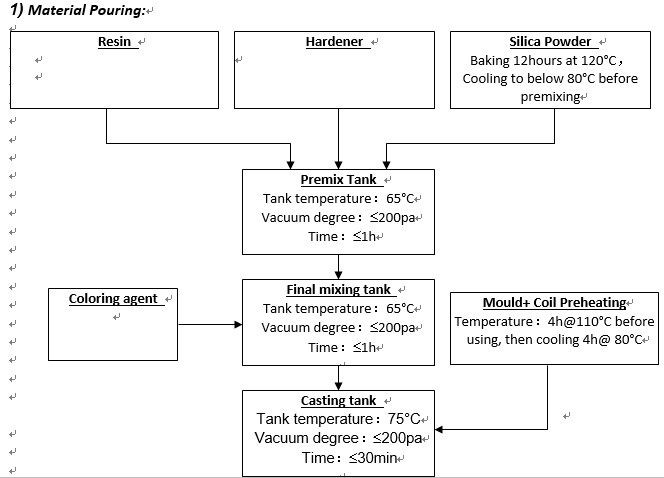

1) Material Pouring:

2) Curing

3) Remark

This process is for reference only, the exact one should be adjusted as per the casting parts and casting equipment.

RELATED PRODUCTS:

|