| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Fire Rated ACP Sheets |

|---|---|

| Brand Name: | richly bound |

| Model Number: | A2 Fire Rated ACP Sheets |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Place of Origin: | CHINA |

| Sheet thickness: | 4.0mm |

| Aluminum layer thickness: | 0.2mm |

| Surface color: | Solid color |

| Surface coating: | PVDF |

| Size: | 1220mm * 2440mm |

| Application fields: | Exterior wall,balcony,ceilings,partitions,doors,column casings,equipment panels,interior decoration |

| MOQ: | 1000 sqm |

| Price: | depends on your needs |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Delivery Time: | usually within 14 working days |

| Payment Terms: | T/T |

| Company Info. |

| Foshan Nanhai Huashi Decoration Material Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Fire Rated ACP Sheets - 4.0mm Thickness, PVDF Coating, 1220mm * 2440mm Size

Product description

The aluminum plastic composite is a unique blend of two divergent materials - metal and non-metal, ingeniously synthesizing the optimal attributes of both. It retains the key characteristics of the original materials, such as aluminum and polyethylene plastic, and overcomes their shortcomings to realize a multitude of superior material properties. This includes its luxurious allure, vibrantly colorful decorativeness, weather resistance, corrosion resistance, impact resistance, fireproofing, dampness resistance, sound insulation, heat insulation, and seismic resistance. Additionally, it features a lightweight construction, ease of manipulation, and convenient transport and installation.

1. Low Mass, High Strength: Possesses an outstanding ratio of

strength to weight. For an equivalent rigidity (E.j), the weight

per unit volume of aluminum composite panels is approximately 60%

of aluminum panels and a mere 30% of steel panels.

2. Superior Adhesive Force: Shows high 180° peel strength. There's

no spontaneous detachment between the aluminum panel and plastic

core material even after enduring long-term usage.

3. Resistant to Weathering: Shows remarkable stability in color and

gloss under extensive outdoor usage, with no detachment of coating,

and a typical lifespan exceeding twenty years.

4.Anti-Corrosive: The surface coating has impressive adhesion and

resists corrosion from acids (10%H2S04), bases (10%NaOH), and

saline mist; the resilience of the PVDF fluorocarbon resin coating

is especially noteworthy.

5.Withstanding Wind Pressure: Its performance reaches national

category A, fulfilling the wind pressure requirements for high-rise

external wall decoration.

6.Fire Resistance: The core layer is made of harmless polyethylene,

flanked by two non-flammable aluminum thin sheets.

Our company

Launched in 1999, we have excelled in producing Aluminum Composite Panels using cutting-edge equipment. Our panels, with their unique attributes, have left a mark on contemporary decoration trends. We are proud to be the first to receive the ISO 9001:2008 certification and have won numerous awards. Our primary brand, "Richly Bound", stands for our extensive range of quality offerings.

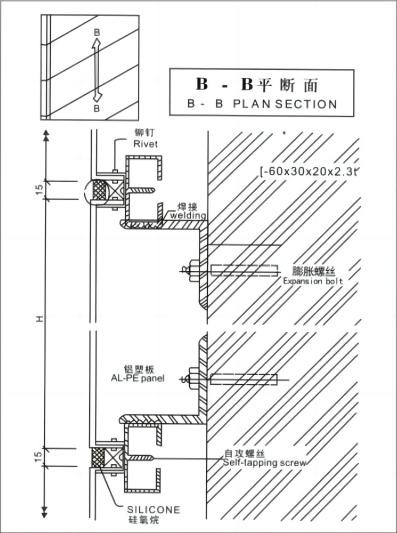

Product installation process diagram

|