| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Membrane Nitrogen Generator |

|---|---|

| Brand Name: | SUMAIRUI GAS |

| Model Number: | OSM |

| Certification: | ISO9001, CE, BV, SGS, TUV, ASME, GOST,NB,NR ETC |

| Place of Origin: | SUZHOU, CHINA |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 100 sets/months |

| Delivery Time: | 30-45 days |

| Packaging Details: | Exporting wooden case /Film packing |

| Material: | Mild steel/Stainless steel |

| Certificates: | CE, ISO, ASME, GOST, KGS, NB etc |

| Capacity: | 1000 CFM |

| Purity: | 95%-99.9% |

| Pressure: | 500 PSI |

| Container: | Yes |

| Movable: | Yes |

| Application: | Purging |

| Condition: | New |

| Warranty: | 1 Year |

| Voltage: | 220v/380v/50-60hz |

| Weight: | Actual Weight) |

| Dimension(l*w*h): | Actual Size |

| Power(w): | 0.5KW |

| Color: | White/customized |

| Technology: | Membrane |

| Name: | nitrogen generator |

| Company Info. |

| Suzhou Sumairui Gas System Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Membrane modular N2 generator for the Bacteria Elimination with capacity 500 scfm purity 95% 500 psi by CE certificates

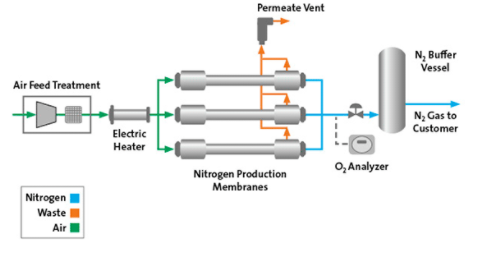

How does membrane technology work?

Membrane nitrogen generators are based on a simple working principle. The main part of a membrane generator is the membrane module (+- 10cm in diameter), filled with small, hollow polymer fibers. First, dry, clean compressed air enters and due to the structure of these fibers parts of the air will flow to the outside of the fiber. This process is called permeation. During this process, water, oxygen and some of the argon exit through the membrane sides of the fibers. In the end, only nitrogen will remain. This is possible since different molecules permeate at different speeds. H2O will permeate very quickly, oxygen takes a little longer. Argon and Nitrogen permeate rather slowly, meaning that they will remain in the fibers long after the H2O and oxygen are gone (some of the Argon will permeate as well, but it would be inefficient to completely remove it from the air stream). Learn more about Nitrogen purity here. Because of the permeation through the fiber wall, an overpressure would occur inside the membrane housing. The fibers would clog and the permeation efficiency would be significantly lowered. To prevent that from happening there is an opening in the housing, the permeate vent, where these 'exhaust' gases (including H2O, oxygen and Argon) can escape.

Nitrogen purity and requirements for the intake air

It is very important for the intake air to be clean and dry before it enters the membrane. If this is not the case, the shallow fibers will quickly clog. In order to prevent this from happening, correct air treatment of the feed air has to be installed. In some cases the needed filters and dryers will already be built into the generator itself. This would mean that, in some cases, no additional filters should be installed between the compressor and generator. The fibers of the membrane can handle water vapor without much problems. It is however very important that the air doesn't contain liquid water, since this will have a detrimental impact on the membrane. Therefore, it is required for a good water separation solution to be in place upstream the generator, a refrigerant dryer for example. Taking care of the intake air of the generator will protect the membrane and ensure a long lifetime. Take a look at a typical installation below.

Choosing between a Membrane and PSA generator

Since the air factor is generally lower in PSA generators, which results in lower operating costs, you might think that choosing between the two is an easy choice. However, there are some notable advantages to using a membrane generator. The first one being the simpler working principle of membrane generators, this affects maintenance costs and results in a smaller footprint of the installation. They also start up faster and are a lot quieter than PSA generators, who typically have to cope with their blow-off noises at the end of each cycle. This last advantage makes a membrane nitrogen generator more suitable for places in which there are a lot of people working. When selecting the right type of generator, it's wise to look at the application it will be used for and then, considering the total package of (dis)advantages, make a choice.

| Item | Nitrogen purity (Nm3/hr) | Dimensions | Weight | ||||

| 90% | 95% | 99% | 99.5% | 99.9% | (L*W*H) mm | KG | |

| OSM15 | 135 | 61 | 23 | 15 | 6.5 | 450*300*1300 | 100 |

| OSM30 | 270 | 122 | 46 | 30 | 13 | 550*500*1300 | 140 |

| OSM60 | 540 | 244 | 92 | 60 | 26 | 900*850*1300 | 200 |

| OSM120 | 1080 | 488 | 184 | 120 | 52 | 1200*1000*1500 | 280 |

| OSM180 | 1620 | 732 | 276 | 180 | 78 | 1500*1200*1500 | 400 |

| OSM240 | 1890 | 854 | 322 | 240 | 104 | 1800*1200*1600 | 520 |

| OSM300 | 2700 | 1220 | 460 | 300 | 130 | 2300*1350*1800 | 600 |

| OSM450 | 4050 | 1830 | 690 | 450 | 195 | 3850*1500*2000 | 800 |

| OSM525 | 4725 | 2135 | 805 | 525 | 227.5 | 4200*1550*2100 | 950 |

| OSM600 | 5400 | 2440 | 920 | 600 | 260 | 5000*1800*2250 | 1050 |

| OSM675 | 6075 | 2745 | 1035 | 675 | 292.5 | 5500*1800*2350 | 1250 |

| OSM750 | 6750 | 3050 | 1150 | 750 | 325 | 5850*1850*2400 | 1500 |

| OSM900 | 8100 | 3660 | 1380 | 900 | 390 | 6500*1950*2400 | 1700 |

| OSM1050 | 9450 | 4270 | 1610 | 1050 | 455 | 7800*2100*2450 | 1950 |

| OSM1500 | 13500 | 6100 | 2300 | 1500 | 650 | 10500*2300*2600 | 2100 |

| OSM1800 | 16200 | 7320 | 2760 | 1800 | 780 | 13000*2350*2600 | 2600 |

|