| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Alloy Steel Flange |

|---|---|

| Brand Name: | Kasugai |

| Model Number: | ASTM A182 F11 ANSI B16.5/B16.47 SO |

| Certification: | ISO PED AD2000 |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L / C , T / T |

| Supply Ability: | 500 ton per month |

| Delivery Time: | 30 - 60 working days |

| Packaging Details: | Seaworthy Packng |

| Product Name: | ASTM A182 F11 ANSI B16.5/B16.47 Alloy Steel Slip-On Flanges |

| Size Range: | 1/2″ to 48″,customized |

| Pressure Class: | 75, 150, 300, 400, 600, 900, 1500, 2500 |

| Thickness: | Sch10S to Sch160 |

| Dimensions: | ASME/ANSI B36.10M ASME/ANSI 36.19M |

| Type: | Slip-on (SO) |

| Company Info. |

| Kasugai Shanghai Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

ASTM A182 F11 ANSI B16.5/B16.47 Alloy Steel Slip-On Flanges

Product Information

| Product Name | ASTM A182 F11 ANSI B16.5/B16.47 Alloy Steel Flanges |

| Size Range | 1/2’ to 48” |

| Pressure Class | 75 150, 300, 400, 600, 900, 1500, 2500, |

| Thickness | Sch10S to Sch160 |

| Standards | ASME/ANSI B16.5/B16.47, JIS B2220 |

| Type | Slip - on Flange ( SO ) |

| Dimensions | ANSI B16.5, Custom Drawings |

| Coating | Anti-rust Paint, Oil Black Paint, Cold and Hot Dip Galvanized, Yellow Transparent, Zinc Plated |

| Origin | China |

| Applications | Offshore, Oil Field, Shipbuilding, Water System, Nature Gas, Pipe Projects, Electric Power, etc. |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, Ultrasonic flaw detector, Magnetic particle detector |

| Test Certificates | Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report |

Standards & Materials: ASTM A182 F11

The ASME B16.5 and ASME B16.47 flanges can be made from ASTM A182 Gr.F11 Class 2 steels by a forging process. They may be furnished in various flange types covering welding neck, slip on, and blind, etc. Both ASME B16.5 and ASME B16.47 have endorsed the use of ASTM A182 Gr. F11 Class 2 in Material Group 1.9, which has the nominal chemical composition of 1.25Cr-0.5Mo-Si. Flanges made from this steel are generally used with maximum working temperature limit of 590°C [1100°F]. It is permissible but not recommended for prolonged use above 590°C [1100°F].

Chemical Composition of ASTM A182 F11 Alloy Flanges

| Grade | C,max | Mn | Si | P, max | S, max | Cr | Mo |

| ASTM A182 F11 | 0.1-0.2 | 0.3-0.8 | 0.5-1.0 | 0.040 | 0.040 | 1.0-1.5 | 0.44-0.65 |

Mechanical Properties of ASTM A182 F11 Alloy Flanges

| Grade | Tensile Strength, min.(MPa) | Yield Strength, min (MPa) | Elongation in 2″, min (%) | Reduction of Area, min (%) | Brinell Hardness (HBW) |

| ASTM A182 F11 | 485 | 275 | 20 | 35 | 143-207 |

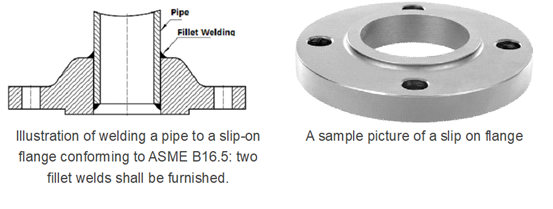

Flange Type: Slip On (SO)

Slip on flange also simplified as SO flange. SO flanges slip over pipes and are designed to bit slightly bigger on the inside than the pipe. They connect to the pipe through a fillet weld at the flange top and bottom. It is used to insert the pipe into the inner hole of flange, as the flange inner diameter is little bigger than the pipe’s outer diameter, pipe and flange could be connected by lap welding at the top and bottom of the flange.

The slip on flange is shorter in length than a weld neck flange, and is used in areas where short tie-ins are necessary or space limitations necessitate its use. Generally, the life span of a slip-on flange connection is about one-third that of the weld neck flange. Despite of additional welding involved during installation, its lower initial cost makes the SO flange preferred over WN flanges by many users. It is generally used in non-corrosive, non-critical, moderate pressure services. Slip on flanges of Class 150 and Class 300 are most commonly seen in utility engineering.

Pressure-Temperature Ratings

Both ASME B16.5 and ASME B16.47 has stipulated pressure-temperature ratings for ASTM A182 F5 steel, which are maximum allowable working gauge pressures in psi units at the temperature in degrees Fahrenheit. The data sheet is divided by Classes: ASME B16.5 flanges are available in Class 150, 300, 400, 600, 900, 1500, 2500; ASME B16.47 Series A are available in Classes 150, 300, 400, 600, 900; and ASME B16.47 Series B are available in Classes 75, 150, 300, 400, 600, 900.

| Temp. °F | Class 75 psi | Class 150 psi | Class 300 psi | Class 400 psi | Class 600 psi | Class 900 psi | Class 1500 psi | Class 2500 psi |

| -20~100 | 145 | 290 | 750 | 1000 | 1500 | 2250 | 3750 | 6250 |

| 200 | 135 | 260 | 735 | 980 | 1470 | 2210 | 3680 | 6135 |

| 300 | 115 | 230 | 700 | 935 | 1400 | 2100 | 3495 | 5830 |

| 400 | 100 | 200 | 670 | 890 | 1335 | 2005 | 3345 | 5570 |

| 500 | 85 | 170 | 645 | 860 | 1290 | 1940 | 3230 | 5385 |

| 600 | 70 | 140 | 605 | 805 | 1210 | 1815 | 3025 | 5040 |

| 650 | 60 | 125 | 590 | 785 | 1175 | 1765 | 2940 | 4905 |

| 700 | - | 110 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 750 | - | 95 | 530 | 710 | 1065 | 1595 | 2660 | 4430 |

| 800 | - | 80 | 510 | 675 | 1015 | 1525 | 2540 | 4230 |

| 850 | - | 65 | 485 | 650 | 975 | 1460 | 2435 | 4060 |

| 900 | - | 50 | 375 | 500 | 745 | 1120 | 1870 | 3115 |

| 950 | - | 35 | 275 | 365 | 550 | 825 | 1370 | 2285 |

| 1000 | - | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1050 | - | - | 145 | 190 | 290 | 430 | 720 | 1200 |

| 1100 | - | - | 95 | 130 | 190 | 290 | 480 | 800 |

| 1150 | - | - | 60 | 80 | 125 | 185 | 310 | 515 |

| 1200 | - | - | 35 | 45 | 70 | 105 | 170 | 285 |

Manufacturing Process

|