| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rotary Lime Kiln |

|---|---|

| Brand Name: | ZHONGKE |

| Certification: | ISO CE |

| Place of Origin: | Henan, China |

| MOQ: | 1 set |

| Price: | $66,000.00 - $780,000.00 / Set |

| Supply Ability: | 100 Set/Sets per Month |

| Product name: | Limestone Calcined Machine |

| Core Components: | PLC, engine, Bearing, Gearbox, MOTOR, GEAR |

| After-sales Service Provided: | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support |

| Power(W): | 800-20000KW |

| Weight: | 10t-2000t, 237 tons, 30-300t |

| Dimension(L*W*H): | According to the type |

| Pre-heater: | Vertical Pre-heater |

| Core Components Warranty: | 3 years |

Cement Plant Production Machine Vertical Shaft Lime Rotary Kiln

Introduction of Rotary Lime Kiln

The rotary kiln produced has advanced structure. It can effectively improve preheating effect with its low resistance vertical preheater. After the material is preheated, the feeding decomposition rate can reach 20%-25%, thus can directly make use of 10-15mm fine fraction materials. The reliable airtight two-ends combination squama make the air leakage factor under 10%. The usage of compound refractory reduces radiation loss.Rotary kiln belongs to building material equipment, which can be divided into cement kiln,metallurgy chemical kiln and lime kiln according to different materials.

Structure of Lime Rotary Kiln

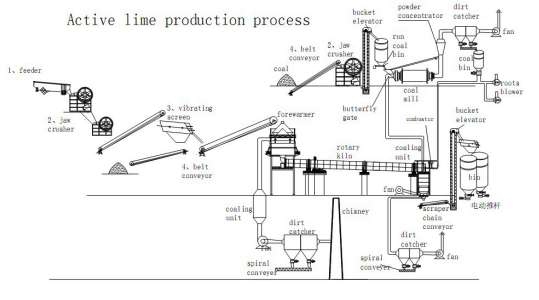

Lime kiln consists of kiln body,feeding device,cloth device, burning device,discharge device,electrical equipment,instrument control equipment,dust removal device,etc.

Different forms of lime kiln,its structure and calcination,process basic same,but the value of equipment has the very big difference.Of course use effect is distinct

Working Principle of Lime Rotary Kiln

Rotary kiln cylinder composed of steel plate, cylinder body with build by laying bricks or stones of refractory lining, and horizontal line into slope, three belting leather in each block supporting device, in the material near the end belting leather across the inner cylinder with tangential spring plate fixed on a big gear ring, which is a small gear meshing. During normal operation, the main drive motor is transmitted to the open-type gear device by the main drive motor, which drives the rotary kiln.Materials are calcined from the end of the kiln. Due to the effect of tilting and slow rotation of the cylinder, the material is along the circumference of a circle and tumbling along the axial direction (from high to low) mobile, continue to complete the process, and generate the clinker kiln hood into the cooling machine cooling.The fuel is sprayed into the kiln by the kiln head, and the waste gas and materials produced in the furnace are exchanged for impact crusher, which is exported by the kiln tail.

Main Technical Parameters:

| Design Capacity(t/d) | 150 | 300 | 600 | |

| Product | Active Lime | Active Lime | Active Lime | |

| preheater | Vertical Pre-heater | Vertical Pre-heater | Vertical Pre-heater | |

| rotary kiln | size (m) | Φ2.5×40 | Φ3.3×50 | Φ4×60 |

| Effective Volum (m3) | 142 | 292 | 575 | |

| Burning temperature | ≤1250 | ≤1250 | ≤1250 | |

| cooler | Grate Cooler | Grate Cooler | Grate Cooler | |

| fuel | Gas Coal Dust | Gas Coal Dust | Gas Coal Dust | |

| Heat Consumption(kJ/kgCao) | 5000-5300 | 5000-5300 | 5100 | |

Parameter of lime stone kiln rotary:

| size (m) | Φ2.5×40 | φ2.8x42 | Φ3x46 | Φ3.2x50 | φ3.2x54 | φ3.6x56 | φ3.8x58 | Φ4x60 | Φ4.3x58 | Φ4.3x64 | Φ4.8x68 |

| Effective Volume (m3) | 142 | 190 | 235 | 292 | 390 | 430 | 505 | 575 | 670 | 738 | 1005 |

| Burning temperature (°C) | 1350/1250 | 1350/1250 | 1350/1250 | 1350/1250 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 |

| capacity (t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 |

other product:

Magnesium oxide rotary kiln

Lime rotary kiln

Cement rotary kiln

Chemical rotary kiln

FAQ

Q1: How long is the warranty of the rotary kiln?

A1: Our warranty period is one year generally.

Q2: How long shall we replace the refractory brick?

A2:Usually 6-12 months(Depends on the time and temperature.)

Q3: Can l visit your factory?

A3:Yes. We warmly welcome you to visit our factory.We will take you

to our customer site to have a real look.We will arrange a car to

pick you up at the Xinzheng International Airport.

Q4: Do you provide equipment operation training?

A4:Yes.We can send professional engineers to the working site for

installation, adjustment, and operation training. All of our

engineers have passports.

Q5: Do you provide whole rotary kiln flow chart?

A5:Yes. Our experienced engineers are specialized in designing

process flow for various project, such as cement production line,

quick lime production line,magnesium production line etc.

Q6: Can you test our samples?

A6:Yes.You can send your samples to us for test and analysis.

Q7:How about price?

A7.Yes, we are factory and are able to give you the lowest price

than market one and we have a policy that “for saving time and

absolutely honest business attitude, we quote as low as possible

for any customer, and discount can be given according to

quantity.contact us.

|