| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | VSI Crusher |

|---|---|

| Model Number: | PLS-700 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiate |

| Payment Terms: | TT, L/C |

| Supply Ability: | 60 Set/Sets per Month |

| Delivery Time: | To be negotiated |

| Packaging Details: | Standard package or as request |

| Brand Name: | CN Crusher |

| Name: | VSI Crusher Manufacturer |

| Max. Feed Size: | 35 |

| Impeller Speed: | 1775-1965r/min |

| Power: | 55-110kw |

| Capacity: | 55-120t/h |

| Weight: | 7500kg |

| Company Info. |

| CN Crusher Equipment Co., ltd |

| View Contact Details |

| Product List |

Quick Details

Vertical Shaft Impactor is widely used for fine crushing and coarse

grinding of metal and nonmetal ores, cement, refractory material,

grinding material, glass raw material, building aggregates,

artificial sand, and all kinds of metallurgical slags. It is

especially suitable for medium hardness materials, high hardness

materials, and corrosion resistance materials, such as carborundum,

emery, magnesia, etc.

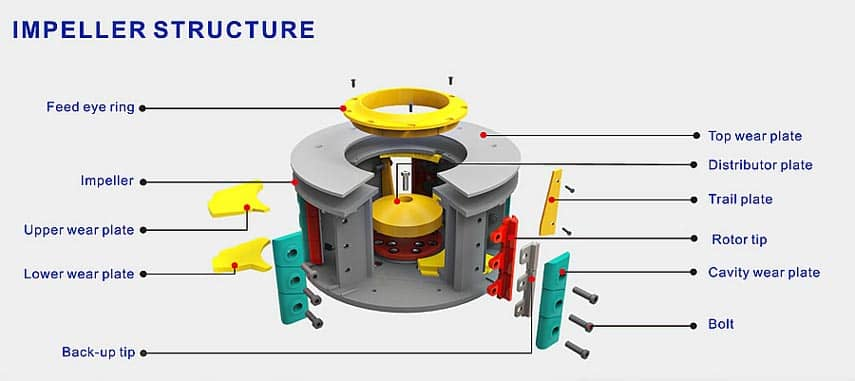

Vertical Shaft Impactor Working Principle

Stone Beat Stone: The materials fall vertically and uniformly from the top of the machine. One part of them enter into the revolving impeller at high speed through the distributor and feed pipe, and are shoot out from the discharge outlet of impeller by the action of the high-speed centrifugal force. Then at high speed they are smashed with another part of the materials that have been distributed around impeller through the distributor. After smashing each other the materials shall form whirlpool and impact many times caused by striking and attrition in the impeller and crushing chamber.

Stone Beat Iron: The materials fall vertically and uniformly from the top of the machine, and enter into the revolving impeller at high speed through the feed pipe. Then they are shot out from the discharge outlets of impeller by the action of the high-speed centrifugal force, and at high speed strike and crush with impact plate around the impeller.

| Model | Max. Feed Size(mm) | Impeller Speed(r/min) | Power(kw) | Capacity(t/h) | Weight(kg) |

| PLS-550 | 30 | 2258-2600 | 30-45 | 24-60 | 4780 |

| PLS-700 | 35 | 1775-1965 | 55-110 | 55-120 | 7500 |

| PLS-850 | 50 | 1320-1720 | 150-320 | 75-345 | 11500 |

| PLS-1000 | 60 | 1240-1460 | 320-500 | 200-585 | 17000 |

| PLS-1200 | 60 | 1040-1300 | 500-630 | 300-715 | 22650 |

Vertical Shaft Impactor is the latest product of authoritative experts from both home and abroad,connecting with quarry,mining present working conditions.

|