| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Welded Pipe Flying Saw |

|---|---|

| Brand Name: | JCCS |

| Model Number: | JCCS-32 |

| Place of Origin: | HeBei China |

| MOQ: | 1 set of |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 Set/Sets per Month |

| Delivery Time: | 15-30 work days |

| Packaging Details: | Usually a high quality steel square tube making machine is loaded in a container. Depends on the size and weight of the machine. |

| Product name: | Cold Cutting Flying Saw |

| Origin: | China |

| Applicable industries: | Building material stores, manufacturing plants, mechanical repair shops, construction works, energy and mining |

| Core components: | PLC, bearing, gear |

| speed: | custom made |

| Type: | Metal cutting tools |

| Advantage: | Stable performance |

| Control System: | CNC controller |

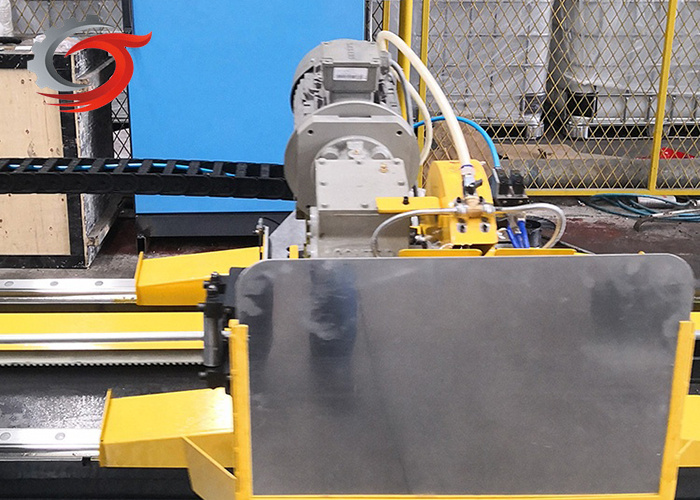

Carbon Steel Pipe Welding Machine Cutting Machine China Automatic Metal Pipe Cutting Machine

Introduction

Cold saw cutting machines are designed to make clean and very

precise in-line cuts without compromising effective production

speed, and on this basis optimize cutting performance parameters.

| material | Q195 Q235 SPCC | |

Cutting range | Round tube:MAX53mm | thick:0.5~2.5mm |

| Square tube:MAX40×40mm | thick:0.5~2.5mm | |

| Rectangular tube:MAX 30×50mm | thick:0.5~2.5mm | |

| Production speed | 120m/min(length 6 meter,dia.≤25mm) | |

| Power supply | AC380V,3PH,50HZ | |

| Mechanical length | 4420*1280*1280mm(as per final drawing) | |

Motor list | Drive:11KW | Yaskawa servo motor |

| feed: 1.8KW | Yaskawa servo motor | |

| saw: 11KW | Siemens AC motor | |

| Clamp | Pneumatic | |

| Carriage protection | Safety bumpers for carriage are equipped at both ends | |

| Equipment document | User’s manual & electrical diagram | |

Features

1. It can improve the quality of sawing workpiece;

2. The high-speed and soft curve reduces the impact of the machine and improves the service life of the equipment;

3. Improve sawing speed and productivity efficiency;

4. Remote operation and intelligent management system;

5. Safe and reliable.

our service

1. Professional pre-sales consultation and after-sales service to

help you find the best solution

2. Discuss technical details with our professional engineers

3. Strictly control the quality and production plan of the cold

flying saw. You will be kept informed of any progress

4. Check the cold flying saw before shipment

5. After the warranty period, spare parts are provided at cost

6. Professional engineers help you increase production, reduce

waste and reduce costs

7. Control the production progress and quality of the machine, and

provide you with detailed information in time

|