| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

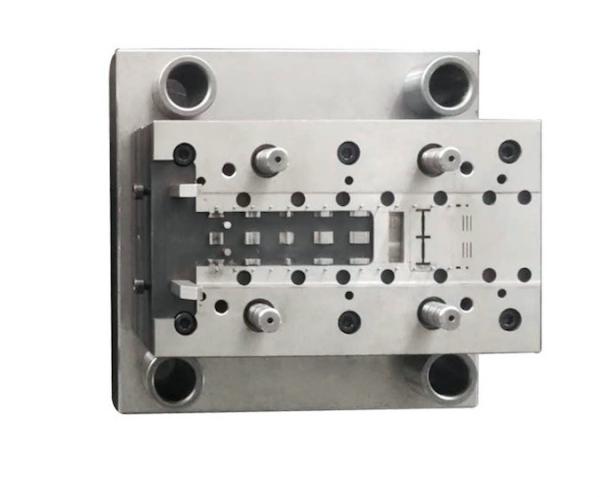

| Categories | Metal Stamping Mold |

|---|---|

| Brand Name: | GT |

| Model Number: | Metal Stamping Mold |

| Certification: | CE / ISO9001 |

| Place of Origin: | Dongguan China |

| MOQ: | 1 mold |

| Price: | Negotiate |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 65 molds / month |

| Delivery Time: | 20 days after 2D 3D confirmed |

| Packaging Details: | Woodencase for packaging mold & Carton Box for packaging products |

| Mold Base: | LKM C50 + P20 for AB , Cast iron etc |

| Product Material: | Aluminium , ADC12 , ADC14 , A360 , A380 , AlSi9Cu3 and so on |

| Shape & Color: | Can be design according to your needs |

| Model: | Sheet metal stamping molds tool and die makers |

| Item name: | Metal Stamping Mold |

| Certificated: | ISO 9001:2015 |

| Shaping Mode: | Die Casting |

| Mold Treatment: | Heat Treatment >HRC45 |

| Company Info. |

| TAKDA PRECISE MOULD FACTORY |

| View Contact Details |

| Product List |

Professionalism

1) Equipment: We own Stamping machines, Hydraulic press machines,

Auto-Turning machines, CNC-Turning machines, Milling machines,

Precision wire cutting machines, more than 160 sets in total;

2) Material: iron, carbon steel, stainless steel, brass, copper,

alloy steel, aluminum, cold rolled steel with various plating;

3) Surface treatment: kinds of plating (Zinc, Nikel, Chrome, Tin,

Ag); Painting, Powder, Anodizing, E-coating, Silkscreen, Heat

treatment, Black oxid

4) Standard/ specification: OEM service as per customers' requests,

within-house tooling design & fabricating;

5) RoHS compliance for export

6) Quality assurance in accordance with ISO9001:2008

7) Concurrent engineering capability on product design

8) Just-in-time manufacturing capability to meet customer's

requirement

9) Tailor-made packaging method according to customer's requirement

Product Name | Power press dies/mould |

Material of Die | DC53., SKH-9, SKD11, A3,SKD61 etc. |

Die Type | Stamping press moulds , stamping die, punching die, sheet metal

mould , progressivedie, terminal die,single die, double die or according to your parts |

Drawing format | igs,stp, prt, asm, pdf, dwg, dxf,Step |

Die Life | 1,000,000-3,000,000 shots |

First Trial | 15-25 days after mold drawing confirmed |

Mould design | Design the mould structure drawing according to your product

drawing or sample, then send to you for confirmation. |

Quality confirm | You will confirm our stamping die quality according to sample. If you need to adjust the product structure, we can help you to

change it further. |

Competitive Advantage:

1. We keep long term cooperation with some world Top Brand on

electronic product area, such Epson,

Canon and Sony.

2. We have successfully gained the quality certificate of ISO 9001

and IGS.

3. We can design and manufacture the mould in different

specification and standard, such as DME,HASCO

and DAIDO.

4. The factory is well equiped with the most advanced testing

instrument, it is effective to ensure the precision

of the mould.

5. Strict quality control;

6. Good After-sale service;

7. On time delivery

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 working days if the goods are in stock. or

it is 15-20 working days if the goods are not in stock, it is

according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge if there has

stock but do not pay the cost of freight.

Product details picture

|