| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Brick Plant Machine |

|---|---|

| Brand Name: | Halstec |

| Model Number: | Tunnel Kiln |

| Place of Origin: | CHINA |

| Certification: | ISO 9001 |

| MOQ: | 1 Set |

| Price: | USD 500,000-900,000 |

| Packaging Details: | Nude in the container |

| Delivery Time: | 60 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1 SET PER 2 MONTH |

| Length: | 120M |

| Kiln Section: | 3.6m 4.2m 4.8m 5.6m etc |

| energy consumption: | 220-280 Kcal |

| Finished Bricks: | Normal Bricks,porous Bricks,decoration Bricks |

| Product Name: | Brick Production Line |

| advantage: | Energy Saving |

| function: | Brick Manufacturing Equipment |

| type: | Brick Manufacturing Plant With Tunnel Klin |

| Company Info. |

| Halstec Engineering Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Masonry Tunnel Kiln 580T Brick Plant Machine With Coal Consumption 220-280 Kcal/Kg, Clay Brick Making,

The Brick Production Line is a fully automatic for brick production that can produce high-quality bricks with a total length of 120M. It is an energy-efficient machine with coal consumption of 220-280 Kcal. It has the capability to produce bricks of various sizes and shapes.

The Brick Production Line is a user-friendly machine that is easy to install and operate. It is equipped with a robust control system that allows for precise adjustments and ensures a smooth production process. The Brick Production Line also comes with a variety of safety features that make it safe and reliable for operation. It is the perfect brick production line machine for those looking for an efficient, reliable, and economical production process.

Halstec is a leading manufacturer in the brick machine production line industry, and we have designed the whole brick manufacturing plant as the demands of the market and customers. This brick machine production line is ISO 9001 certified, and comes with a minimum production capacity of 100000 bricks per day.

All machines and kilns are prefabricated in Chinese workshop, when all cargoes are ready, will deliver to the customer country by the containers. Halstec engineers will go to customer project location, to finish the kiln assemble, machine installation, and whole line commissioning work, etc. Halstec provides you a turn-key solution. Choose Halstec, choose the way to success.

| Technical Parameters | Description |

|---|---|

| Raw Material | Clay, Shale or Slurry, Coal Gangue, etc |

| Kiln Type | Hoffman kiln, mansory tunnel kiln, rotary kiln etc. |

| Service | including design, drawing provide, kiln assemble, commissioning etc |

| Kiln Section | from 3.6m to 16.8m |

| Capacity | 100,000-600,000 Bricks Per Day |

| Advantage | Energy Saving |

| Operation Mode | Fully Automatic |

| Brick Size | 240x115x53mm 250x120x75mm 200x100x50mm, as customer needs |

| Energy Consumption | 220-280 Kcal |

| Product Name | Brick Production Line |

Brick Plant Machine Technical Support and Services

We provide comprehensive technical support and services for our Brick Plant Machine. Our experienced and highly trained technical staff are available 24/7 to ensure that you have the support you need to operate your Brick Plant Machine effectively and efficiently.

We offer a range of services, including: Installation of Brick Plant Machine, Maintenance and repair, Technical advice and guidance, Software updates and upgrades, Training...

To make sure you get the most out of your Brick Plant Machine, we also provide a range of additional services, including:

Preventive maintenance, Performance monitoring, Parts and supplies ordering, Troubleshooting...

Our team with experienced technicians will provide you with the best service and support. Contact us to learn more about our Brick Plant Machine Production Line.

Packaging and Shipping for Brick Plant Machine:

At the factory, Brick Plant Machines are prefabricated, then deliver by containers. The machines are well fixed and fastened with steel wire to ensure they are safe during the sea shipping.

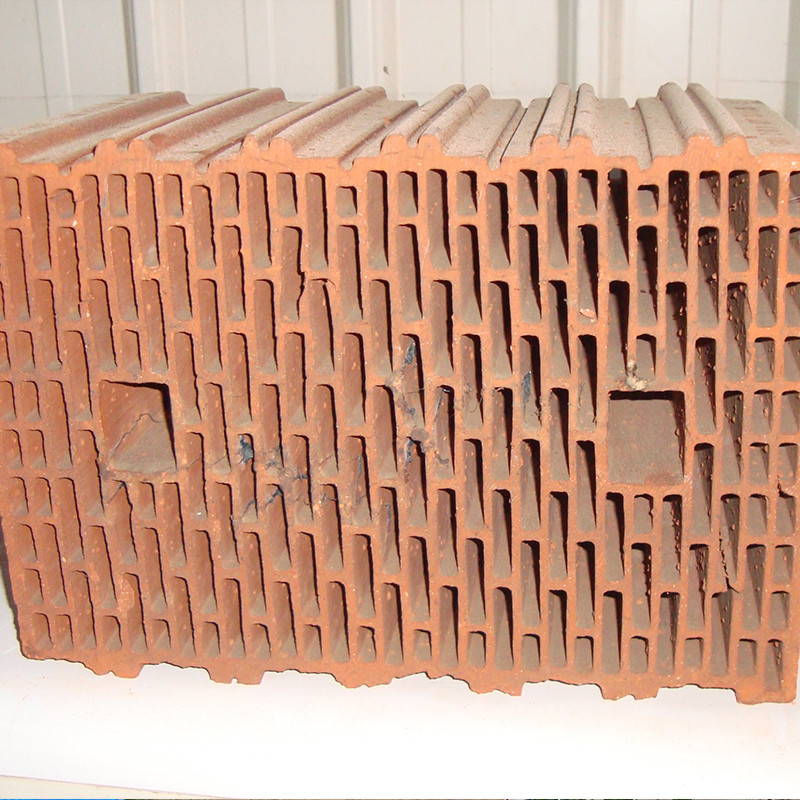

Finished Brick Samples

According to different usage purpose, finished bricks can be divided into out-wall decoration bricks, and inner-wall construction bricks.

Out-wall decoration bricks come with smooth surface and uniform color , and normally burning fuel is natural gas or coal powder, which is showered into the burning kiln by specific tube system. Out-wall decoration bricks also can be called as Face bricks.

Inner-wall construction bricks, normally featured with rough surface, but higher strength. Burning fuel for inner-wall construction bricks is coal, which can be added into the raw materials, or threw from the top of burning kiln.

Below is the sample for finished bricks, the size, shape and hole rate can be customized as the production requirements of clients.

Customers Show

With around 20 years experience of international trading, Halstec has set up more than 200 brick factories all over the world, such as Indonesia, Uzbekistan, India, Myanmar, Vietnam, South Africa, Zimbabwe, Bangladesh, etc. Below is the glimpse of our clients, hope can be your partner in very soon future.

FAQ:

|