| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Fluid Bed Dryer |

|---|---|

| Brand Name: | JingSu ShengMan |

| Model Number: | ZLG |

| Certification: | CE and ISO9001 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | USD20000-USD300000 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10sets |

| Delivery Time: | 60-90days |

| Packaging Details: | Plywood Cases |

| Condition: | New |

| warranty: | 1 year |

| Voltage: | Customized |

| Area of fluidized bed: | 0.9-14.4 |

| temperature of inlet air: | 70-140℃ |

| temperature of outlet: | 40-70 |

| capacity to vapor moisture: | 20-420kg/h |

| Heating Method: | Gas Electricity Steam |

| Material: | 304 316 |

| Core Components: | Bearing, Pump, Gear, Motor, Gearbox, PLC, Engine |

| Type: | Fluidized Bed Dehydrator |

| Company Info. |

| Jiangsu Shengman Drying Equipment Engineering Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

304/316 Vegetable Vibrating Fluid Bed Drying Machine with GMP standard

Scope for application

Vibrating Fluid Bed Dryer is suitablity in Pharmaceutical and

chemical industries: All kinds of press tablet and granule, boric

acid, borax, dihydroxybenzene, malic acid, maleic acid and so on;

Foodstuff and construction material industries: Less, monosodium

glutamate, edible sugar, edible salt, mine residue, bean, seeds and

so on;

It can also used for raw materials to add up damp or cooling and so

on.

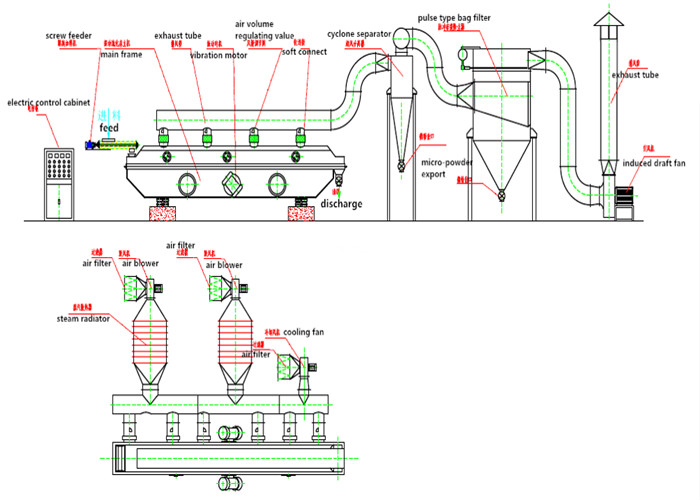

Principle of work

Raw material is fed into the machine from the inlet and moves

forward continuously along with the level of fluidized-bed under

the action of vibration. The hot air passes through fluidized-bed

and carries out hot heat exchange with damp raw material. Then the

damp air is exhausted out through cyclone separator and duster and

the dry raw material is discharged through discharge outlet.

Features of Fluidized Bed Dryer

The vibration is created by motor. It is stable in operation and

convenient in maintenance, low noise and long life.

High heat efficiency, raw material is heated evenly and heat

exchange is fully used and dry capacity is high. Compared with

ordinary drier, the energy can be saved about 30%. The state of

fluidization is uniform and no dead gaps or broken phenomenon so as

to have dry, cool products.

It is good in regulation and wide in suitability. The thickness of

raw material layer and movable speed inside the machine and the

amplitude can be adjusted.

It is small for damaging the surface of raw material. The equipment

can be used for drying raw materials that are easy broken. The

drying effect can not be affected even if raw materials have

irregular shape.

It is effective to prevent cross pollution between raw material and

air because the equipment adapts fully closed structure. The

environment of operation is clean.

You can string multi-set to raised capacity of raw materials, such

as polyacrylamide.

3. Technical parameters

| MODEL | area of fludized -bed | temperature of inlet air | temperature of outlet air | capacity to vapor moisture | vibration motor | |

| ㎡ | ℃ | ℃ | kg/h | model | power kw | |

| ZLG3*0.3 | 0.9 | 70-140 | 40-70 | 20-35 | YZS8-6 | 0.75*2 |

| ZLG0.45*0.6 | 2.7 | 70-90 | YZS15-6 | 1.1*2 | ||

| ZLG6*0.45 | 2.7 | 80-100 | YZS15-6 | 1.1*2 | ||

| ZLG6*0.6 | 3.6 | 100-130 | YZS20-6 | 1.5*2 | ||

| ZLG6*0.9 | 5.4 | 140-170 | YZS30-6 | 2.2*2 | ||

| ZLG7.5*0.6 | 4.5 | 130-150 | YZS30-6 | 2.2*2 | ||

| ZLG7.5*1.5 | 11.25 | 230-330 | YZS50-6 | 3.7*2 | ||

| ZLG8*1.8 | 14.4 | 290-420 | YZS75-6 | 5.5*2 | ||

Remark:

1. Parameters above in the table are regular model for reference;

2. We could make special model / size according to the customer's actual situation or requirement, please contact sales team to konw more details about vegetable dryer.

Applications

I> Inorganic: borax, boric acid, glass fibers, ammonium hydrogen fluoride, potassium permanganate, sodium perborate, ammonium thiocyanate, sodium thiocyanate, cobalt sulfate, nickel sulfate, zinc sulfate heptahydrate, ammonium chloride, calcium, strontium chloride, sodium chlorate, strontium, copper sulfate pentahydrate, sodium chlorite, sodium sulfite, ammonium nitrate, calcium nitrate, sodium nitrate, potassium bromide, sodium bromide, sodium sulfate, sodium salt

II> Organics: oxalic acid, succinic acid, hydroquinone, p-nitrobenzoic acid, fumaric acid, pentaerythritol, resorcinol, catechol, calcium hypochlorite, sodium silicate, GDL, sodium gluconate, thiourea, sorbitol, dicyandiamide, iminodiacetonitrile, itaconic acid

III> Fertilizer: potassium dihydrogen phosphate, calcium hydrogen phosphate, monoammonium phosphate, ammonium sulfate, magnesium sulfate heptahydrate

IV> Pesticides: Imidacloprid granules, granules glyphosate

V> Polymer: High-absorbent resin, a polystyrene resin, sodium polyacrylate

VI> Chemicals: washing powder

VII> Chemical additives: methyl cellulose, polyacrylamide, hydroxyethyl cellulose

♦ Food and beverage industry:L-arabinose, acesulfame, erythritol, trehalose, caramel, tartaric acid, coffee, bread crumbs, milk powder, citric acid, potassium citrate, sodium citrate , maltitol, xylose, xylitol, Ru refined, sugar, potassium sorbate, salt, sodium saccharin, monosodium glutamate, sodium iso-VC,

♦ Pharmaceutical medical industry:honeysuckle, taurine, vitamin C

♦ Animal husbandry and fishery industry:canola ,seeds

After-sale service:

Provide considerate services to minimize clients’ worries.

1. Assist clients to prepare for the first construction scheme.

2. Install and debug the equipment.

3. Train the first-line operators.

4. Examine the equipment.

5. Take initiative to eliminate the troubles rapidly.

6. Provide technical support.

7. Establish long-term and friendly relationship.

Service commitment:

1. Provide clients one-year warranty to make sure the machine work

well.

2. We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely.

3. Send every client a preferential quotation.

|