| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | IMD Lens |

|---|---|

| Brand Name: | HXSIMD |

| Model Number: | IMD-210 |

| Certification: | ISO9001/ISO14001/ISO16949 |

| Place of Origin: | SHENZHEN,CHINA |

| MOQ: | 10K pcs |

| Price: | According to drawing requirements |

| Payment Terms: | T/T, D/A, D/P, T/T, Western Union |

| Supply Ability: | 3000 Pieces per Day |

| Delivery Time: | 12 work days |

| Packaging Details: | standard packing (43cm*33cm*36cm, 10KG) |

| Feature: | HIGH GROSS |

| Process: | In Mold Decoration |

| Material: | ABS+PET |

| Shape: | According to your demand |

| technology: | IMD Injection Moulding |

| category: | Plastic decorative accessories |

IMD Plastic Lenses Lightweight Affordable Shatterproof And Colorful

The main advantages of IMD plastic lenses are:

1. Lightweight and lighter than glass lenses, making it difficult to slide when worn on the nose.

2. The price is cheaper compared to glass lenses.

3. Easy to dye and can be made into various colors.

4. Strong impact resistance and less prone to fragmentation.

5. The production efficiency of the product is high, the price is low, and it can meet the demand for lightweight and short products.

In short, plastic lenses have unique advantages in terms of lightweight, affordable, shatterproof, and diverse colors, and are widely used in eyewear lenses.

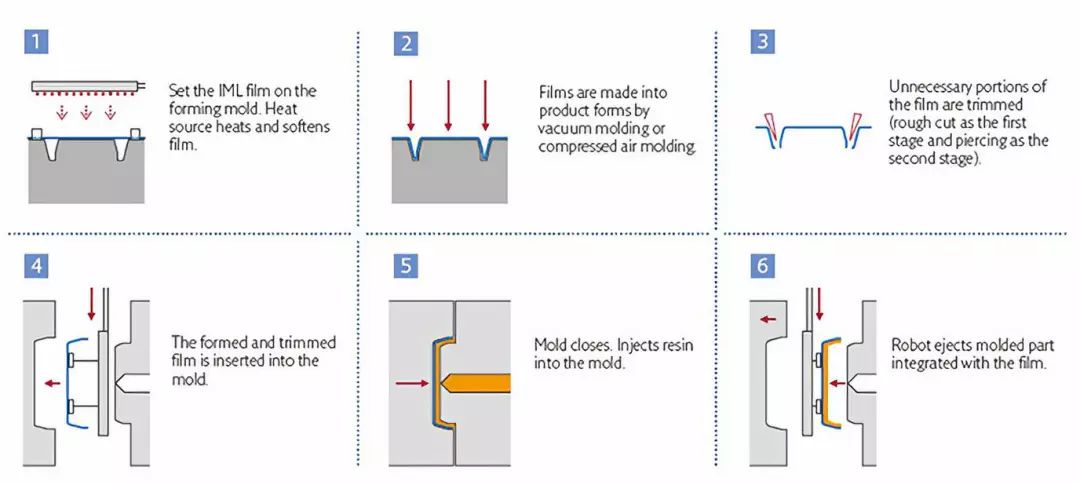

IMD Parts process introduction:

In Mold Decoration(IMD): use PET film coated on the surface as the carrier to print ink pattern layer, adhesive and ink curing on the printing surface. Then it is heated and baked for hot pressing forming and trimming. Put the shaped PET film into the injection mold cavity through manual or mechanical hand to fill the plastic, and melt the adhesive to bond the PET film with the ink pattern layer to form a whole with the plastic under high temperature.

Expansion area:

In addition to PET materials, it can also be cloth, PU leather, wood chips, bamboo chips and other sheet materials

Why choose us

We are the first professional IMD PARTS manufacturer in China,Founded in 2009, the company's industrial park covers an area of more than 30000 square meters, has a high-precision dust-free workshop, and has nearly 100 excellent management personnel, 35 engineering and technical personnel, 50 quality personnel, a total of nearly 500 employees, more than 500 injection molding equipment, and a monthly production capacity of nearly 15 million pieces; From engineering research and development to mold production, diaphragm printing, diaphragm molding, diaphragm injection molding, inspection and packaging, there is a complete process production process.

Full-process dust-free workshop operation

Full-process dust-free workshop operation

Our company has won the honors of high-growth enterprise, industry benchmark enterprise, contract-abiding and creditworthy enterprise, high-tech enterprise, etc

HXS has become a long-term partner of more than ten top 100 enterprises in the world

|