| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | High Temperature Alloy |

|---|---|

| Brand Name: | KAIXIN |

| Model Number: | KX-Alloy Nitronic 50 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 200KG |

| Price: | To negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50~80TONS per MONTH |

| Delivery Time: | 45~60days |

| Packaging Details: | Wooden Box, size as per guests request |

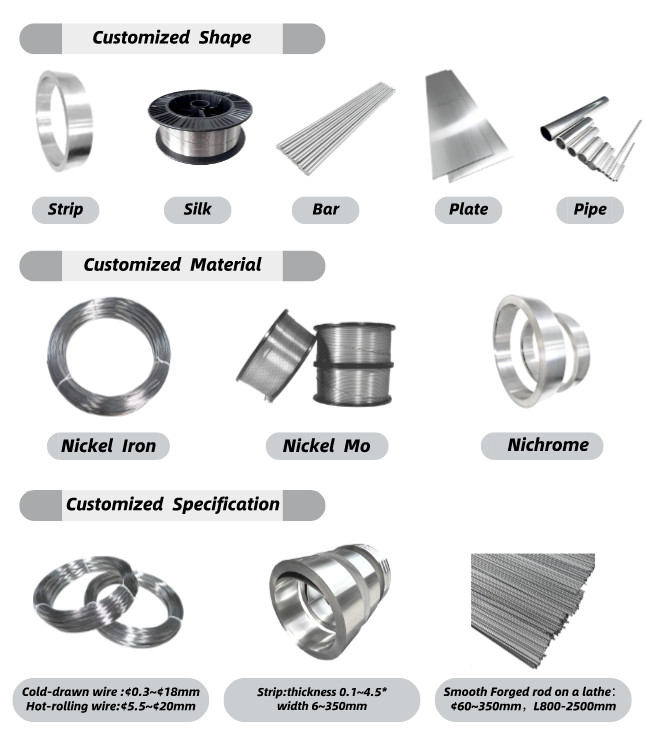

| Shape: | Wire, Strip, Rod, Tube, Plate |

| Alloy Type: | Nickel-based Deformed Superalloy |

| Raw Materials: | NI11.5-13.5%,CR20.5-23.5% |

| Executive Standard: | ASTM |

| Delivery State: | Sosoloid |

| Application: | Oil and gas, offshore, chemical and Marine industries |

| Features: | High strength, corrosion resistance, fatigue resistance and wear resistance |

| Size: | Negotiable |

| Company Info. |

| Danyang Kaixin Alloy Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

KX 1.3964 Light Rod Plate Structural Operating Temperature Range For High Temperature Alloy

Product Description and Application

The 1.3964 is also known as W.nics.Nitronic 50 , UNS S20910, AWS 165

Alloy 1.3964 is an austenitic stainless steel with corrosion resistance and strength that no other commercial material has. Its corrosion resistance is higher than type 316 and 316L and its yield strength at room temperature is approximately twice as them. Alloy1.3964 is widely used in a variety of corrosion resistance and high strength applications, such as Marine engineering, food processing, paper industry, chemical industry, power industry, aerospace and medical equipment. Alloy1.3964 can be used to manufacture components such as containers, pipes, pumps and valves in food processing, paper, chemicals,power and etc field, as well as high-pressure and high-temperature equipment, which are resistant to acid corrosion and wear.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Element | Min % | Max % |

| C | – | 0.06 |

| Si | – | 1 |

| Mn | 4 | 6 |

| Ni | 11.5 | 13.5 |

| Cr | 20.5 | 23.5 |

| S | – | 0.03 |

| P | – | 0.04 |

| Mo | 1.5 | 3 |

| N | 0.2 | 0.4 |

| V | 0.1 | 0.3 |

| Nb/Cb | 0.1 | 0.3 |

| Fe | bal |

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |

|