| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | High Temperature Alloy |

|---|---|

| Brand Name: | KAIXIN |

| Model Number: | KX-Alloy HT188 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 200KG |

| Price: | To negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50~80TONS per MONTH |

| Delivery Time: | 45~60days |

| Packaging Details: | Wooden Box, size as per guests request |

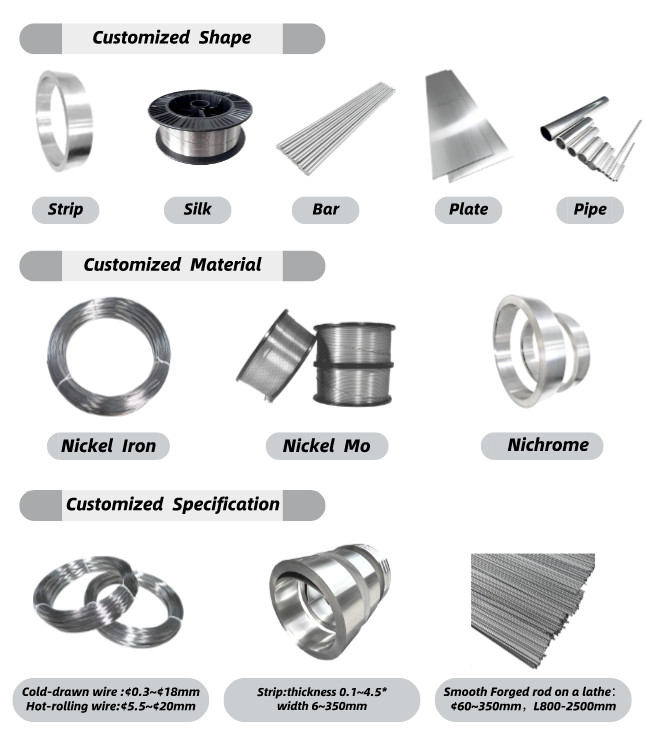

| Shape: | Wire, Strip, Rod, Tube, Plate |

| Alloy Type: | Solid Solution Strengthened Cobalt base Superalloy |

| Raw Materials: | NI20-24%,CR20-24% |

| Executive Standard: | ASTM,GB/T14992 |

| Delivery State: | Sosoloid |

| Application: | Use for Aerospace engine and shuttle |

| Features: | Thermal strength, oxidation resistance and good weldability |

| Size: | Negotiable |

| Company Info. |

| Danyang Kaixin Alloy Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

KX GH5188 Uns Light Rod Plate Structural Operating Temperature Range For High Temperature Alloy

Product Description and Application

GH5188 is also known as UNSR30188, W.N.2.4683,Hayness 188

GH5188 is solid solution strengthened cobalt base superalloy. Add

14% tungsten for solid solution strengthened and make the alloy

have excellent high temperature thermal strength. Add high content

chromium and trace lanthanum and make the alloy have good oxidation

resistance at high temperature and satisfactory forming, welding

and etc technological properties. It is suitable for the

manufacture of aeroengine parts requiring high strength below 980℃

and oxidation resistance below 1100℃. The alloy is widely used

abroad in the manufacture of high-temperature components of gas and

missiles, such as combustor, tail nozzle and heat exchanger parts

in the nuclear energy industry. The high temperature components

that aero-engine combustion chamber flame cylinder and guide vane

made of this alloy have passed long-term test and been put into

production in China.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting

Furnace(ESR)

| Alloy Grade | C | Mn | Si | P | S | Ni | Cr | Fe |

| GH5188 | 0.05-0.15 | 0.2-0.5 | ≤0.015 | ≤0.020 | ≤0.015 | 20.0-24.0 | 20.0-24.0 | ≤3.0 |

| B | Cu | La | Ag | Fb | Bi | W | Co | |

| ≤0.015 | ≤0.07 | 0.03-0.12 | ≤0.001 | ≤0.001 | ≤0.0001 | 13.0-16.0 | Rem |

| Density | 9.09g/cm3 |

| Magnetic Energy | Nil |

The alloy can be circulating test at 900℃ ↔260℃ for 200h dynamic

thermal corrosion test,corroded by gas in the combustion device.

The alloy corrosion resistance is better than GH3536 alloy in

polluted environment containing Na2SO2 and NaCl

a) Forged bar and ring,1180℃±10℃,Choose the cooling rate to ensure

the product mechanical properties ,HB≤293

b) Cold-rolled Plate and Strip,1165℃-1230℃,Rapid cooling, holding

time according to the product section thickness

c) Hot-rolled Plate,1170℃-1190℃,cooling,HV≤282

| Standard Number | Variety | Heat Treatment | Tensile Property | Durability | Room Temperature Hardness(HV) | Other Properties | |||||||

| θ/℃ | MPa | MPa | % | θ/℃ | MPa | r/h | % | ||||||

| ≧ | ≧ | ||||||||||||

| GJB 3317A | Hot-rolled Plate | Standard | 20 | 380 | 860 | 45 | 815 | 165 | 23 | 10 | ≤ 282 | Grain Size≧Grade 4 | |

| 927 | 76 | 23 | 15 | ||||||||||

| Q/5B 4003 | Thin Plate | Standard | 20 | 380 | 860 | 45 | 927 | 76 | 23 | 15 | --- | Bend,resist oxidation | |

| 650 | 250 | 620 | 40 | ||||||||||

| Q/5B 4002 | Strip | ≤0.51 | 20 | 380 | 860 | 40 | 927 | 62 | 23 | 8 | --- | Bend 180°and resist oxidation | |

| 650 | 250 | 620 | 40 | ||||||||||

| >0.51 | 20 | 380 | 860 | 45 | 927 | 76 | 23 | 5 | --- | ||||

| 650 | 250 | 620 | 50 | ||||||||||

| Q/5B 40222 | Bar | Standard | 20 | 380 | 860 | 45 | 927 | 90 | 23 | 15 | HB≤302 | Resist oxidation | |

| Q/5B 4014 | Ring forging | 20 | 380 | 860 | 45 | 927 | 83 | 23 | 15 | HB≤293 | Resist oxidation | ||

① Endurance test at any temperature | |||||||||||||

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |

|