| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Inconel Alloy |

|---|---|

| Brand Name: | KAIXIN |

| Model Number: | KX-Alloy738 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 200KG |

| Price: | To negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50~80 TONS per MONTH |

| Delivery Time: | 45~60days |

| Packaging Details: | Wooden Box, size as per guests' request |

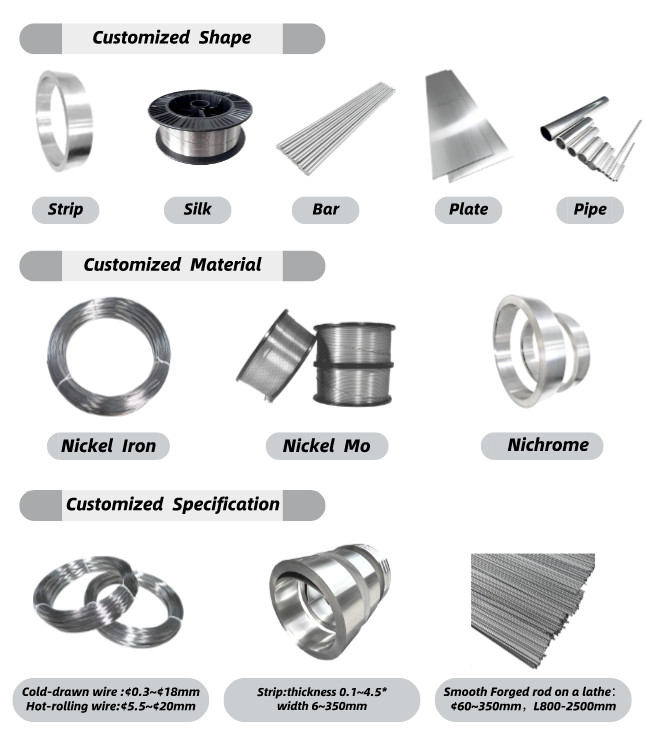

| Shape: | Wire,Strip,Rod,Pipe,Plate |

| Alloy Type: | Precipitation Hardening High-temperature Alloy |

| Raw Materials: | NI Rem,CR18-21%,Co12-15% ,MO3.5-5.0% |

| Executive standard: | ASTM |

| Delivery State: | Sosoloid |

| Application: | Manufacture turbine disc, working blade, high temperature fastener, flame cylinder shaft and turbine casing and etc parts |

| Features: | Fatigue resistance, oxidation resistance, corrosion resistance |

| Size: | Negotiable |

| Company Info. |

| Danyang Kaixin Alloy Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

KX Inconel 738 Nickel Alloy Wire Round Bar Tube Steel Sheet Light Rod on Inconel Alloy

Product Description and Application

Inconel738 is also known as GH4738, Inconel738Waspaloy(USA), NC20K14(France)

Inconel738 is that Ni-Cr-Co Precipitate-hardening deformed superalloy, the use temperature is below 815℃. Cobalt, chromium and molybdenum are added to the alloy for solution strengthening, aluminum and titanium are added to form γ’ phase, boron and zirconium are added to purify and strengthen the grain boundaries. The alloy has high yield strength and fatigue resistance at 760℃~870℃. It has high oxidation resistance and corrosion resistance in gas turbine atmosphere below 870℃.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| C | Cr | Ni | Co | Mo | Al | Ti |

| 0.03-0.10 | 18.0-21.0 | Rem | 12.0-15.0 | 3.50-5.00 | 1.20-1.60 | 2.75-3.25 |

| B | Zr | Fe | Mn | Si | P | S |

| ≤ | ||||||

| 0.003-0.010 | 0.02-0.08 | 2.0 | 0.10 | 0.15 | 0.015 | 0.015 |

| Density | 8.24g/cm3 |

| Melting Point | 1260-1320℃ |

| Magnetic Energy | Nil |

Product Heat Treatment Institution

1080℃±10℃, 4h, air cooling +840℃, 24h, air cooling +760℃, 16h, air cooling. Can produce bar, forging billet, strip, pipe, wire and etc., Usually delivered without heat treatment, the plates are delivered after solution treatment

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |

|