| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Heavy Duty Slurry Pump |

|---|---|

| Brand Name: | SHIZA |

| Model Number: | 14 / 12 ST - |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | based on quantity |

| Supply Ability: | 200sets monthly |

| Delivery Time: | 15days |

| Packaging Details: | wooden case |

| Structure: | Double Casing |

| Drive Type: | CV, DC(Z), ZV(Z), CR(Z) |

| Impeller: | 5 Closed Vans |

| Certificate: | CE, ISO9001 |

| Application: | Slurry Pumping |

Product overview

14 / 12 ST - heavy duty, horizontal slurry pumps. High efficiency transfer of abrasive and high density slurries with extended wear life and reliable service intervals. M pumps feature a rugged cast iron construction with replaceable wear liners available in 27% chrome white iron, rubber or urethane to suit a wide range of applications, slurry types and consistencies. M Horizontal Slurry Pumps are 100% fully interchangeable with the most common slurry pump design in the mining industry.

(R) slurry pumps continuous pumping of highly abrasive, high density slurries with minimal maintenace requirements and can be applied Multi-staged in series.

The positions of the pump outlet can be positioned at an interval of 45°according to different requirements.

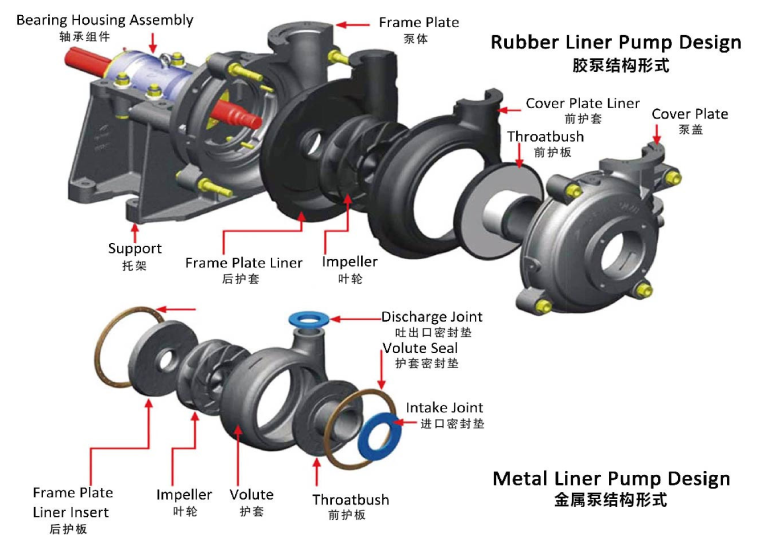

Both metal or rubber liners and impellers, or a combination of both, are interchangeable within the same pump to facilitate use.

cantilever, horizontal and centrifugal pump shafts can be sealed by packing seals or centrifugal type seals.

A removable cartridge type grease lubricated bearing assembly can be replaced with the pump base in-situ.

Polyurethane, stainless steel, Hastelloy 276-C, ceramic and various hard wearing alloys are available on request.

Typical Applications:

Tailings

Heavy Mining

Ash Handling

Cyclone Feeds

Pulp and Paper

Corrosive Slurries

Coal Preparation

Mineral Processing

Aggregate Processing

Heavy Refusal Removal

Materials

A05, Ultrachrome 27% Cr

A07, 15/3 Cr-Mo Iron

A49, Ultrachrome 28% Cr Low C

R26, Natural Rubber

R33, Natural Rubber, Reinforced

Type meaning

| Type meaning for mineral centrifugal slurry pump | |

| 14 / 12 ST-R | |

| 14 | Pump inlet size (inch ) 3 |

| 12 | Pump outlet size (inch)2 |

| ST | Bracket type |

| slurry pump | |

| R | R-Rubber liner pump |

14 / 12 ST - Capacity Control

During the operation of the slurry pump, attention should be paid

to the temperature and leakage of the packing gland. Normal packing

leakage should not exceed 10-20 drops per minute.

In the pump operation, if the slurry pump can take in air and it

can be solid, it will make an abnormal sound and vibrate

accordingly.

In the pump operation, if the backup valve of the standby machine

leaks and the switching valve is always open, it should be noted

that the backup machine is reversed due to the reverse flow.

When the pump regulates the flow during normal operation, it is not

possible to reduce the flow rate by reducing the opening of the

pump suction line valve. Otherwise, the pump inlet flow will be

insufficient and the pump will cavitation.

In the pump operation, for the bearings that need cooling water,

pay attention to the temperature and quantity of water, and try to

keep the bearing temperature within the specified range.

slurry pump start: Check the entire unit as follows before

starting.

(1) The pump should be placed on a firm foundation to withstand the

full weight of the pump to eliminate vibration and tighten all

anchor bolts.

(2) Pipes and valves should be supported separately. There are

seals at the pump flange. When tightening the coupling bolts,

please pay attention to the metal lining of the pump is higher than

the flange. At this time, the bolt should not be tightened too much

to avoid damage to the gasket.

(3) Rotate the shaft by hand according to the direction of rotation

of the pump. The shaft should be able to drive the impeller to

rotate, and there should be no friction. Otherwise, the impeller

clearance should be adjusted.

(4) Check the steering of the motor. Make sure that the pump

rotates in the direction of the arrow marked on the pump body. Note

that the pump is not allowed to rotate in the opposite direction,

otherwise the impeller thread will trip, causing damage to the

pump.

(5) When the transmission is directly connected, the pump shaft and

the motor shaft should be accurately centered. When the belt is

driven, the pump shaft and the motor shaft should be parallel, and

the position of the sheave should be adjusted so as to be

perpendicular to the groove to avoid severe vibration and wear.

(6) A detachable short pipe shall be installed at the suction pipe

of the pump. The length shall be sufficient to disassemble the pump

cover and replace the wearing parts to facilitate the inspection of

the pump.

(7) shaft seal inspection: the expeller shaft seal pump, because of its different stop seal structure, so when the pressure relief cover with oil cup, it is necessary to add grease through the oil cup, grease recommended calcium-sodium grease.

Performance table

| MODEL | ALLOWABLE MATING | MATERIAL | CLEAN WATER PERFORANCE | IMPELLER | |||||||

| MAX.POWER | LINER | IMPELLER | Q Capacity | H Head | Speed | Max. Eff. | NPSH | VANES NO. | IMPELLER DIA | ||

| (KW) | m3/h | L/s | (m) | n(r/min) | (%) | (m) | (mm) | ||||

| 1.5/B- | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2--4 | 5 | 152 |

| RU | RU | 10.8-25.2 | 3--7 | 7-52 | 1400-3400 | 30 | 3 | ||||

| 1/1.5B- | 15 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

| 2/1.5B- | 15 | M | M | 32.4-72 | 9--20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

| RU | RU | 25.2-54 | 7--15 | 5.5--41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 | ||

| 3/2C- | 30 | M | M | 39.6-86.4 | 11--24 | 12-64 | 1300-2700 | 55 | 4--6 | 5 | 214 |

| RU | RU | 36-75.6 | 10--21 | 13-46 | 1300-2300 | 60 | 2--4 | 5 | 213 | ||

| 3/2D-HH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

| 4/3C- | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4--6 | 5 | 245 |

| RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3--5 | ||||

| 4/3E-HH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2--5 | 5 | 508 |

| 6/D- | 60 | M | M | 162-360 | 40-100 | 12-56 | 800-1550 | 65 | 5--8 | 5 | 365 |

| RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3--5 | 5 | 365 | ||

| 6/4S-HH | 560 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3--8 | 5 | 711 |

| 6S-HH | 560 | M | M | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4--12 | 5 | 711 |

| 8/6E- | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2--9 | 5 | 510 |

| RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5--10 | 5 | 510 | ||

| 10/8E-M | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4--10 | 5 | 549 |

| 10/8ST- | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4--10 | 5 | 686 |

| RU | RU | 540-1118 | 150-330 | 12-50 | 400-750 | 75 | 4--12 | ||||

| 12/10ST- | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | ||||

| 14/12ST- | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3--08 | 5 | 965 |

| RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3--10 | ||||

| 16/14TU- | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4--10 | 5 | 1067 |

| 20/18TU- | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5--10 | 5 | 1370 |

Construction Design

|