| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ceramic Pin |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | XF-125 |

| Certification: | ISO9001-2005 |

| Place of Origin: | China |

| MOQ: | 1 pieces |

| Price: | USD1.21-5.16 |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram, D/P, D/A |

| Supply Ability: | 10000 pieces month |

| Delivery Time: | 15 working days after the order confirmed |

| Packaging Details: | intertional carton box |

| Item name: | 95% 99% Alumina ceramic pin |

| Features: | High strength Polished |

| Color: | Black white blue or custom |

| material: | alumina ceramic |

| MOQ: | 1 PCS |

| Delivery: | 7 days |

| Shipping: | DHL EMS UPS FEDEX TNT |

| OEM: | welcome |

| Precision: | +- 0.001mm |

| Finishing: | polished |

High Strength 95% 99.5% Alumina Ceramic Pin For Assembly In Vacuum Environment

| Product Name | High Strength 95% 99.5% Alumina Ceramic Pin For Assembly In Vacuum Environment |

| Material | Alumina |

| Color | White, Black |

| OD | 0.2mm - 50mm, And According to drawings |

| Length | 5mm - 400mm, And According to drawings |

| Surface Roughness | Ra0.05 |

| Torlerance | +/- 0.001mm |

| Lead time: | 15 - 30days |

| Max. working temperature | 1500 -1700 °C |

| Samples | Avaliable |

| Shipping: | Air Express (DHL/UPS/TNT/ FedEx) or Ocean Shipping |

1. High temperature resistance: 99.7% Al2O3 rods can stand 1800C at most. 95% Al2O3 rods can stand 1500C at most.

2. Good abrasive resistance: 99.7% Al2O3 rods, 3.9g/cm3, 95% Al2O3 rods 3.6g/cm3.

3. Good insulating property.

4. Tight tolerance: we can grind and polish the outer surface and length. Size tolerance can be +/-0.02mm after machining.Surface roughness can reach to Ra0.2um.

5. Fast delivery, we have large quantity alumina ceramic rods and blanks in stock.

6. Inspection, each single rods will be tested before shipping.

7. Low shipping cost, we have long time cooperation with shipping company, which can provide us very low prices.

Ceramic adapter plate,Ceramic centering pin,Ceramic connectors,Ceramic spinner,Ceramic roller

Ceramic blade,Ceramic brackets,Ceramic disc,Ceramic insulator,Ceramic rod,ceramic atomizer

ceramic fuse pin,ceramic nozzle,ceramic ferrule,ceramic necklace,ceramic ornament,alumina ceramic plate, ceramic cylinder, ceramic guide, ceramic pin, ceramic bushing, ceramic brick,ceramic injection molding,ceramic bushings,ceramic smoking pipe, ceramic spacer,ceramic piston pump,ceramic part

ceramic heating element vaporizer e cigarette, al2o3 ceramic, ceramic donut atomizer, alumina ceramic disc, alumina ceramic sheet , ceramic alumina , ceramic pressure sensor , ceramic sheet,

ceramic washer, zirconia ceramic plate, ceramic insert, white ceramic ring, ceramic shaft

ceramic pump, ceramic piston, ceramic nail, ceramic insulators, ceramic rod 3mm , ceramic dowel pin

ceramic pin gage , alumina ceramic parts , ceramic burr , ceramic proppant , ceramic needle

ceramic grinder, alumina ceramic rod , alumina ceramic ring, ceramic conical burr , ceramic heater rod

ceramic gear , machinable ceramic, ceramic arms , white ceramic ornaments , sustained high temperature on ceramics

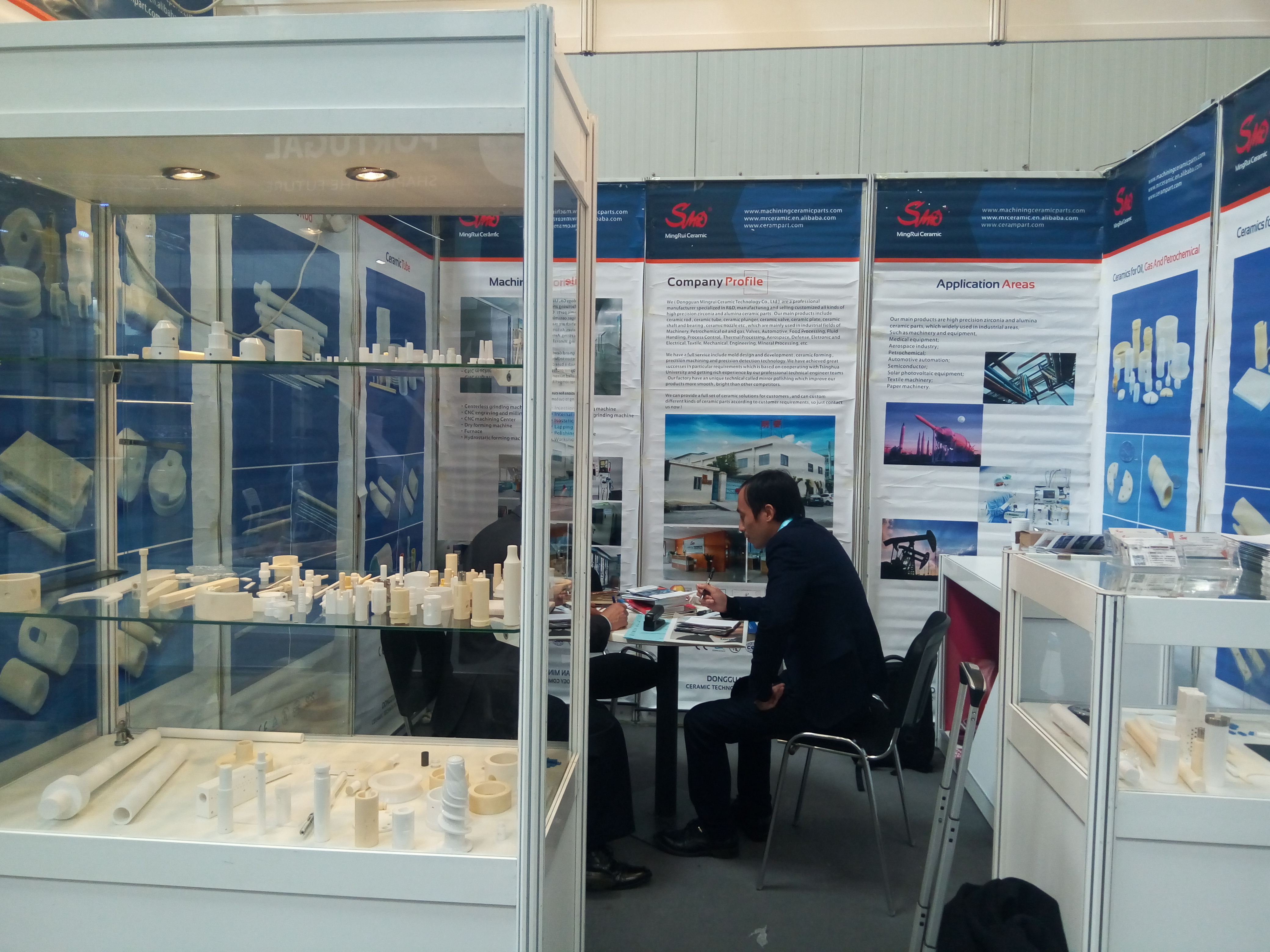

Mingrui offers you a wide range of production facilities like extrusion, injection moulding, pressing and casting. Depending on product geometry and quantities, we will choose the suitable technique for your products.For the final finishing of the parts we use CNC machining centres, equipped with diamond tools in order to meet high accuracies.

Our aim is to offer the ideal solution for any application. Our engineers therefore offer custom solutions that range beyond our existing product portfolio. With our well-equipped industrial development facilities, we produce innovations that can be rapidly commercially exploited.

Properties Sheet of zirconia and alumina :

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

|