| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Alumina Ceramic Parts |

|---|---|

| Brand Name: | Mingrui |

| Model Number: | Customized |

| Certification: | ISO9001:2015,,CE |

| Place of Origin: | China,Guangdong |

| MOQ: | 1 pieces |

| Price: | negotiable |

| Payment Terms: | Western Union, L/C, T/T, D/P, D/A, MoneyGram |

| Supply Ability: | 500 pieces week |

| Delivery Time: | 15-25 working days after the order confirmed |

| Packaging Details: | Packed in PP bags or sponge tray, then put in standard export carton packing. |

| Name: | ceramic chamber |

| process: | cnc machining |

| Features: | high temperature |

| Usage temperature: | 1500℃ |

| Working pressure: | 10MPa |

| Material: | alumina |

| Electrical Insulation: | Excellent |

| Corrosion Resistance:: | High |

| Business type: | Manufacturer |

High Temperature Assembled Alumina Ceramic Chamber for Laboratory

Key words : Ceramic Chamber

1. 99 alumina,abrasion-resistant formulations, dry-pressed molding.

Ceramic Chamber Application:

1. Industrial Insulating, Sealing and protecting materials

2. Electric and thermal insulation materials for electric

industryInsulation materials for instrument-equipment

3. Insulating materials for motor industry

4. Filling materials for expansion slot

5. Isolating materials as the sinter resistance

6. Sealing gasket for molten metal

Ceramic Chamber Advantage:

1. Low thermal conductivity

2. Low thermal capacity

3. Resistance to thermal shock

4. Does not asbe stos, excellent corrosion resistance, does not

react with modern aluminum

5. Excellent electric isolation and sound insulation

6. Strong but pliable in texture, highly pressure resistance.

| Properties | Units | 95 Alumina | 99 Alumina |

| Density | g / cm³ | 3.65 | 3.92 |

| Water absorption | % | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 |

| Poisson's ratio | / | 0.21 | 0.22 |

| HV Hardness HV | MPa | 1400 | 1650 |

| Flexural Strength @ room temperature | MPa | 280 | 310 |

| Flexural Strength @700°C | MPa | 220 | 230 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 |

| Max use temperature | °C | 1500 | 1750 |

| Resistance to acid alkaline | / | high | high |

| Dielectric Constant | / | 9.5 | 9.8 |

| Dielectric Strength | KV/mm | 16 | 22 |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 |

1. Are you a manufacturer ?

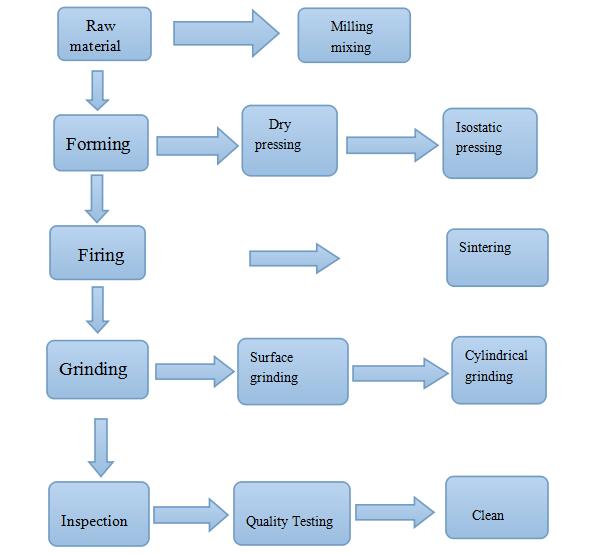

Yes we are a ceramic manufacturer . We proceed with the whole

process start from Powder material to forming , sintering ,

machining, marking , inspection , packing , we do the whole process

.

2. Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to

the product complexity .

3. What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.

|