| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicone Injection Molding |

|---|---|

| Brand Name: | SZOMK |

| Model Number: | HSI16 |

| Certification: | ISO9001:2015, SGS |

| Place of Origin: | Guangdong, China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Paypal |

| Supply Ability: | 100 piece per month |

| Delivery Time: | 15-30 working days |

| Packaging Details: | Standard carton or customized |

| Material: | 2316、H13、S136H、718、420、2738。 |

| Tolerance: | 0.01-0.1mm, Negotiable |

| Number of Mold Parting Surfaces: | Multiple parting surfaces |

| Cavity Number: | Multi cavity mold |

| Mold Installation Method: | Semi-fixed mold, Stationary mold |

| Main Processing Equipment: | Electric spark lathe, Quadratic Element, Polishing machine, Spectrometer, Milling machine, Hardness Tester |

| Company Info. |

| Shenzhen Futian Huaqiang Electronic World OMK Sales Department |

| Verified Supplier |

| View Contact Details |

| Product List |

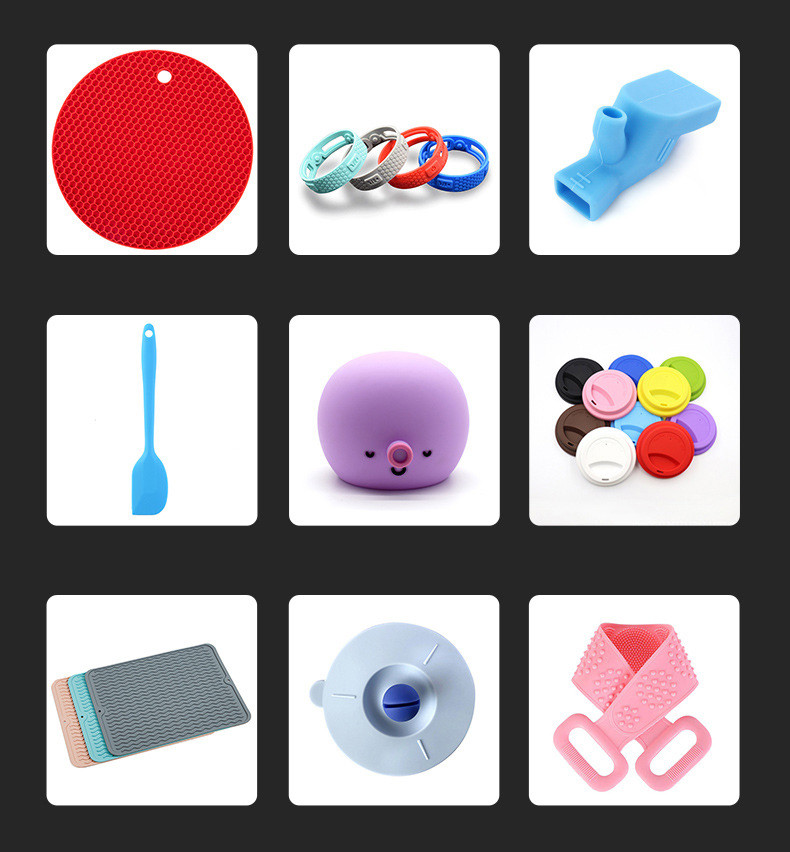

High Precision Molding Inject Mold Customized Liquid Silicone Rubber Molding

Description:

The production process of silicone molds can be customized according to customer needs to meet the needs of different customers. Silicone molds not only have the advantage of producing various shapes and sizes, but also can meet the special requirements of customers, such as color, material, etc., to meet the needs of different customers for various standards.

Application:

Medical devices

syringe gaskets

mechanical seals

candy molds

sealing rings

water retaining rings

Features:

| Name | Silicone Injection Molding |

| Material | VMQ, PDMS, HCR, EPDM, NBR, HTV |

| Service | Sticker, ultrasonic welding, plastic CNC, RFI/EMI shielding coating, custom PC plate, cutout, acrylic plate, flame retardant, laser engraving, Change Material UL94-V0 |

| Design Software | 3D&2D |

| Drawing Format | step, stp, igs, dwg, prt, pdf, stl(for 3D print),etc. |

| Production Ability | 250000 piece per month |

| Lead Time | 30-40 working days |

| Assembly & Test | Professional assembly and testing factory |

| Package | Wood case, standard carton, pallet or customized |

Advantage:

Provide rapid sample manufacturing: We are able to quickly manufacture samples, allowing customers to understand product quality and performance before formal production.

Provide competitive prices: We provide customers with competitive prices to ensure that they receive both high-quality service and affordable prices.

Having the ability to quickly respond to customer needs: We are able to quickly respond to customer needs and provide fast customization services to ensure timely production progress.

FAQ:

Q: Can you guarantee the delivery time?

A: Yes, we will develop a production plan according to customer requirements to ensure delivery is completed within the specified time.

Q: What is the manufacturing cycle of your silicone injection mold?

A: The manufacturing cycle varies depending on the product, usually between 20 and 40 days. At the same time, we also optimize the production plan based on customer needs.

Q: Does the production process meet environmental requirements?

A: Yes, our production process strictly complies with environmental requirements to ensure that it does not cause pollution to the environment.

Q: Does your factory have any relevant confidentiality policies?

A: Yes, we have a comprehensive confidentiality policy that can ensure the security of customer design and product information.

Q: What is the price of silicone injection molds?

A: The price of silicone injection molds varies depending on factors such as specifications and materials, but we will provide customers with high-quality products at a reasonable price.

Q: Can you guarantee product quality?

A: Yes, we ensure strict control over all aspects of the production process to ensure stable product quality.

|

|