| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Bottom Printer Slotter Die Cutter |

|---|---|

| Brand Name: | KECHENG |

| Model Number: | KC-PG1224 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1SET |

| Price: | Negotiated |

| Payment Terms: | TT,L/C |

| Supply Ability: | 60 sets/year |

| Delivery Time: | 100-120 working days |

| Packaging Details: | film packaging and carton |

| Name: | Bottom Printing Printer Gluer Inline |

| Colors: | 1 - 6 colors |

| Max feeding: | 1200*2500mm |

| Max printing: | 1150*2400mm |

| Registering: | +/-0.5mm |

| Convey type: | Roller transfer or vacuum transfer |

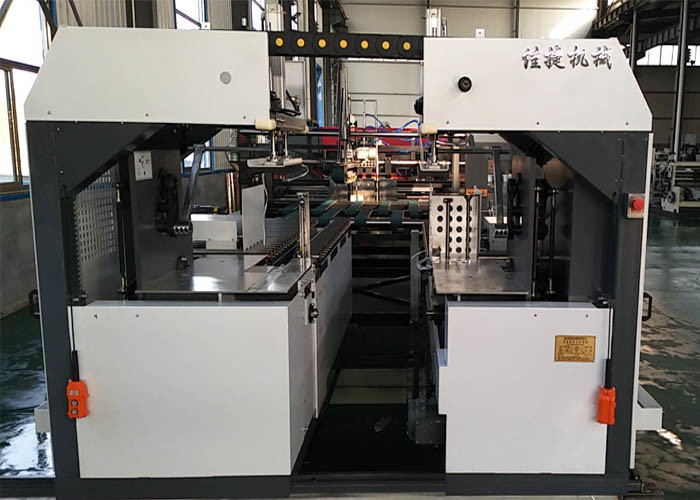

Corrugated Carton Making Machine Bottom Flexo Printing Printer Slotter Gluer Bundler Inline

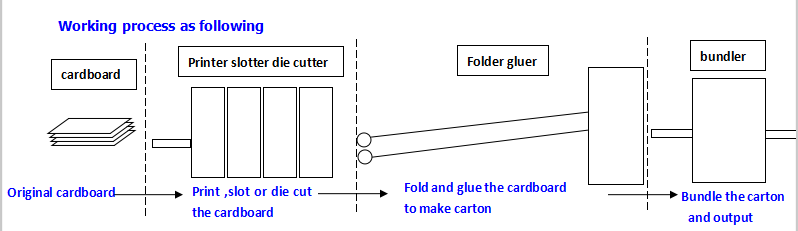

Corrugated Carton Making Machine Bottom Flexo Printing Printer Slotter Gluer Bundler Inline consist of lead edge feeder,bottom printing unit, slotter unit,folder gluer and bundler.The printing unit has roller transfer and vacuum transfer for option.Drying unit is for option.Rubber roller ink distribution or doctor blade chamber ink distribution for option. This line can save much more labor, it just need one time from cardboard to carton, especially without fish tail.

Technologic parameter

| Model | KC-PG920 | KC-PG1224 | KC-PG1228 | KC-PG1628 |

| Printing type | Bottom printing | Bottom printing | Bottom printing | Bottom printing |

| Max working speed | 250pcs/min | 200pcs/min | 200pcs/min | 180pcs/min |

| Max feeding size | 900*2100mm | 1200*2500mm | 1200*2900mm | 1600*2900mm |

| Max skipping feeding size | 1100*2100mm | 1400*2500mm | 1400*2900mm | 1800*2900mm |

| Min feeding size | 300*650mm | 350*720mm | 350*720mm | 420*750mm |

| Max printing size | 880*2000mm | 1150*2400mm | 1150*2800mm | 1550*2800mm |

| Cardboard thickness | 2-11mm | 2-11mm | 2-11mm | 2-11mm |

| Register | +/-0.5mm | +/-0.5mm | +/-0.5mm | +/-0.5mm |

| Slotting precise | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm |

| Die cutting precise | +/-1.5mm | +/-1.5mm | +/-1.5mm | +/-1.5mm |

| Max slotting depth | 210mm | 285mm | 285mm | 385mm |

| Slotting interval | 260*75*260*75mm | 270*85*270*85mm | 270*85*270*85mm | 285*100*285*100mm |

| Gluer speed | Sychronized with printer | Sychronized with printer | Sychronized with printer | Sychronized with printer |

| Bundling speed | 15-20bundles/min | 15-20bundles/min | 15-20bundles/min | 15-20bundles/min |

Features

BOTTOM PRINTING PRINTER

1 Sun alike lead feeder makes feeding easily and stable,make sure the high speed and high registering.all the baffles adjusted by electric control

2 Alarm will ring for safty reminding when open or close the unit

3 Emergency stop string install at the every unit for safe working.

4 All gears are made of 20CrMnTi,undergoes quenched and precised grinded for good printing, long life service and low running noise.

5 All the rollers undergo precise treatment,grinded and plated with rigid chrome and make balance rectification

6 Feeding wheel on the feeding roller are quick-movable by manual.

7 All the fuctions adjusted by computer control

8 Roll to roll transfer or vacuum transfer for operation at printing unit

9 Registering:+/-0.5mm

10 Doctor blade chamber or rubber roller ink distribution for option

11 Automatic ink washing system installed.

12 Automatic zeroing among the unts of feeding,printing,slotting and die cutting

13Automatic reposition after washing the printing plate during printing

14 Pre-creasing wheel,big creasing wheel and second creasing wheel at the slotting unit make the cardboard creasing better for folding .

15 Single shaft slotting or double shaft slotting for option

16 9CrSi or SKD slotting knife for option

17 Die cutting pressure are pneumatic or electric control

18 Anvil cover brand CUE,DEPAK,MAXDURA for option

19 Anvil cover repair knife installed

FOLDER GLUER

1 Gluer speed sychorized with printer

2 Second creasing wheel make the creasing line better for folding

3 The blower on the top to blow the waste for good gluing

4 Upper and down belt extension can be adjusted as per different cardboard

5 The vacuum system make the feeding stable and easy to rectify the cardboard folding

6 Rectification structures avoid joint forming the fish tail

7 Inserting type collection or Drop type collection for option

8 Spray gluing system or wheel gluing system for option

9 The convery arm can be adjusted automatically according to the different slotting interval

10 Good quality convey belt for long service time.

BUNDLER(OPTION)

1 Connect with folder gluer

2 Can move in lateral direction

3 Pneumatic flapping structure make the carton tidy and easy to bundle

4 Special string mouth design, makes the string output smooth and never broken

5 Easy to maintain and operate

6 Bundling speed 15-20 bundles per minute.

7 Single or double circular bundling for option

|