| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rotary Disc Filter |

|---|---|

| Brand Name: | Biocell |

| Model Number: | ZP1-4 |

| Certification: | ISO9001 |

| Place of Origin: | Wuxi China |

| MOQ: | 1 unit |

| Price: | To Be Negotiated |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 units per month |

| Delivery Time: | 30-45 days |

| Packaging Details: | Wooden Box |

| Item Name: | Volute Sludge Dewatering Machine |

| Material: | Stainless Steel |

| Surface Treatment: | Nickle Plated |

| Colour: | Grey, Blue |

| Head Type: | Socket Pan Head |

| Power: | 2.9 KW |

| Number Of Filter Discs: | 4 pcs |

| Single Disc Filter Area: | 1.45 ㎡ |

| Motor Brand: | SEW Or Tsubaki Or NORD |

| Industry: | Wastewater Treatment, Pure Water Process |

| Function: | Filtering Suspended Matter |

| Packing: | Wooden Box |

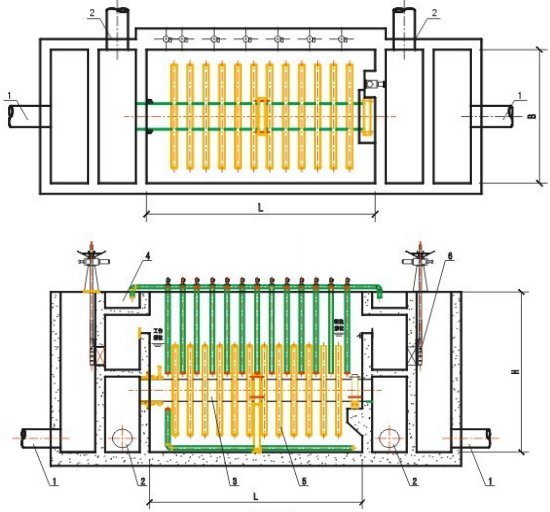

Screw Sludge Dewatering Machine For Filtration Wastewater Treatment

Overview

The fiber turntable filter is a new generation of high-efficiency

filtration technology innovated by our factory on the basis of the

traditional turntable filter.

This technology is used in the advanced treatment unit for removing

SS in the advanced sewage treatment process, and the part can be

removed in combination with the additional chemicals, Phosphorus,

turbidity, COD and other pollutants. It has the advantages of

simple system structure, convenient operation and maintenance, and

small footprint. low energy consumption specialty. New sewage

treatment plants have been built in cities, sewage treatment plants

have been upgraded, reclaimed water reuse, surface water

purification, and other aspects all have been widely used.

Parameters

| Model | Filter Disc Diameter(m) | Number Of Filter Discs (pcs) | Single Disc Filter Area (㎡) | Rated Throughput (T/d) | Total Installed Power (kw) | Net Size Inside The Tank LXWXH(mm) |

| ZP1-4 | 1 | 4 | 1.45 | 1100 | 2.9 | 1800X1600X2000 |

| ZP1-8 | 1 | 8 | 1.45 | 2200 | 3.1 | 2900X1600X2000 |

| ZP1-12 | 1 | 12 | 1.45 | 3320 | 3.2 | 4200X1600X2000 |

| ZP1-14 | 1 | 14 | 1.45 | 3850 | 3.4 | 4800X1600X2000 |

| ZP1-16 | 1 | 16 | 1.45 | 4450 | 5.7 | 5500X1600X2000 |

| ZP1-20 | 1 | 20 | 1.45 | 5500 | 5.8 | 6700x1600x2000 |

| ZP1-24 | 1 | 24 | 1.45 | 6650 | 5.9 | 7900x1600x2000 |

| ZP1-28 | 1 | 28 | 1.45 | 7750 | 6.0 | 9100x1600x2000 |

| ZP1-30 | 1 | 30 | 1.45 | 8300 | 6.2 | 10500x1600x2000 |

| ZP2-4 | 2 | 4 | 5.8 | 4450 | 2.9 | 1800X2800X3500 |

| ZP2-6 | 2 | 6 | 5.8 | 6650 | 3 | 2500X2800X3500 |

| ZP2-8 | 2 | 8 | 5.8 | 8900 | 3.1 | 3100X2800X3500 |

| ZP2-10 | 2 | 10 | 5.8 | 11000 | 3.2 | 3700X2800X3500 |

| ZP2-12 | 2 | 12 | 5.8 | 13200 | 3.3 | 4200X2800X3500 |

| ZP2-14 | 2 | 14 | 5.8 | 15500 | 5.4 | 4800X2800X3500 |

| ZP2-16 | 2 | 16 | 5.8 | 17800 | 7.7 | 5400X2800X3500 |

| ZP2-20 | 2 | 20 | 5.8 | 22000 | 8.1 | 6600X2800X3500 |

| ZP2-24 | 2 | 24 | 5.8 | 26500 | 8.3 | 7800X2800X3500 |

| ZP2-28 | 2 | 28 | 5.8 | 31000 | 8.5 | 9000X2800X3500 |

| ZP2-30 | 2 | 30 | 5.8 | 33400 | 8.7 | 10500X2800X3500 |

| ZP3-4 | 3 | 4 | 13.1 | 10000 | 3.2 | 2000X4000X4700 |

| ZP3-6 | 3 | 6 | 13.1 | 15000 | 3.3 | 3000X4000X4700 |

| ZP3-8 | 3 | 8 | 13.1 | 20000 | 3.4 | 3600X4000X4700 |

| ZP3-10 | 3 | 10 | 13.1 | 25000 | 5.5 | 4200X4000X4700 |

| ZP3-12 | 3 | 12 | 13.1 | 30000 | 5.6 | 4800X4000X4700 |

| ZP3-14 | 3 | 14 | 13.1 | 35000 | 5.7 | 5400X4000X4700 |

| ZP3-16 | 3 | 16 | 13.1 | 40000 | 6 | 6000X4000X4700 |

| ZP3-20 | 3 | 20 | 13.1 | 50000 | 6.2 | 7200X4000X4700 |

| ZP3-24 | 3 | 24 | 13.1 | 60000 | 8.6 | 8500X4000X4700 |

| ZP3-28 | 3 | 28 | 13.1 | 70000 | 8.8 | 9700X4000X4700 |

| ZP3-30 | 3 | 30 | 13.1 | 75000 | 9 | 9700X4000X4700 |

Technical characteristics

1. The treatment effect is stable and reliable: the filter cloth

aperture is less than 10um, and the filter cloth fluff is thick.

Filters smaller particles.

2. Small footprint: Change the traditional plane filtering

mechanism and adopt the vertical turntable setting. All sides of

the turntable are the effective filter area. Several times the

filtering area can be obtained in a limited plane area, which

greatly improves the filtering efficiency.

3. Small head loss: The design is unique, the internal head loss of

the filter is only 0.2-0.3M, and it is also possible to avoid

lifting.

4. Project investment is low: the volume of the filter is small and

the internal structure is simple. The production cost is low, the

installation cost is very low, and the total project investment of

the filter tank is more than 30% less than that of sand filter and

other filters.

5. Low operating cost: The operating cost is less than 0.005

yuan/ton.

6. High backwashing efficiency, low water consumption and short

cycle: modular standard design, the backwashing water volume is

only that of traditional sand filter

1/2~1/3, no need to stop when backwashing.

7. The filter cloth has stable performance and larger flux: the

filter cloth adopts a new type of nanofiber material, the fiber

material has a memory function, impurities are not easy to adhere,

and the service life is long.

8. Easy to construct, install, operate and manage: run fully

automated control. Filtration, anti-suction cleaning, etc. are all

controlled by the program, and are equipped with multiple

protections, and no special personnel are required for daily

operation and management.

|