| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Filtration Wastewater Treatment |

|---|---|

| Brand Name: | Biocell |

| Model Number: | MDS352 |

| Certification: | ISO9001 |

| Place of Origin: | Wuxi China |

| MOQ: | 1 unit |

| Price: | To Be Negotiated |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 units per month |

| Delivery Time: | 30-45 days |

| Packaging Details: | Wooden Box |

| Product Name: | Volute Sludge Dewatering Machine |

| Material: | Stainless Steel 304 |

| Surface Treatment: | Nickle Plated |

| Colour: | Grey, Blue |

| Head Type: | Socket Pan Head |

| Power: | 3.75 KW |

| DS Standard Capacity: | 240 kg/h (High Concentration) |

| Sludge Treatment Capacity: | 12 m3/h (20000 mg/L) |

| Motor: | SEW Or Tsubaki Or NORD |

| Application: | Wastewater Treatment, Pure Water Process |

| Function: | Filtering Suspended Matter |

| Packing: | Wooden Box |

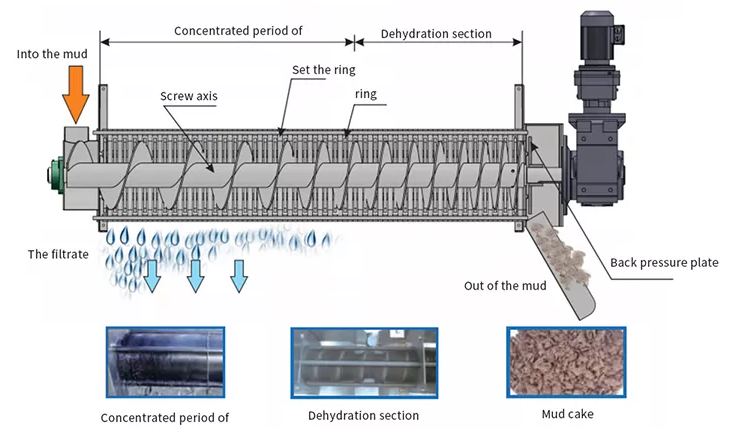

Screw Sludge Thickener Filtration Wastewater Treatment Machine

The Principle Of The Inner Flow Mesh Plate Grille

The geared motor drives the sprocket to rotate, and the sprocket drives the mesh plate to rotate continuously; the sewage enters the grille from the water inlet and is filtered by the mesh plate. After filtering, the water flows to the outside of the mesh plate, and the dirt is trapped on the inner surface of the same plate. Continuously rotate the belt to the top; the backwash system washes the outside of the washing plate, and the dirt is washed into the slag collection tank under the action of the washing water, and flows out of the sewage outlet together with the washing water.

| Model | DS Standard Capacity(kg/h) | Sludge Treatment Capacity(m³/h) | ||||||

| Low Concentration | High Concentration | 2000mg/L | 4000mg/L | 10000mg/L | 20000mg/L | 25000mg/L | 50000mg/L | |

| MDS101 | 3 | 6 | 1.5 | 0.75 | 0.6 | 0.3 | 0.24 | 0.12 |

| MDS131 | 6 | 12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 | 0.24 |

| MDS132 | 12 | 24 | 6 | 3 | 2.4 | 1.2 | 0.96 | 0.48 |

| MDS201 | 12 | 20 | 6 | 3 | 2 | 1 | 0.8 | 0.4 |

| MDS202 | 24 | 40 | 12 | 6 | 4 | 2 | 1.6 | 0.8 |

| MDS301 | 30 | 60 | 15 | 7.5 | 6 | 3 | 2.4 | 1.2 |

| MDS302 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS303 | 90 | 180 | 45 | 22.5 | 18 | 9 | 7.2 | 3.6 |

| MDS351 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS352 | 120 | 240 | 60 | 30 | 24 | 12 | 9.6 | 4.8 |

| MDS353 | 180 | 360 | 90 | 45 | 36 | 18 | 14.4 | 7.2 |

| MDS354 | 240 | 480 | 120 | 60 | 48 | 24 | 19.2 | 9.6 |

| MDS401 | 100 | 170 | 50 | 25 | 17 | 8.5 | 6.8 | 3.4 |

| MDS402 | 200 | 340 | 100 | 50 | 34 | 17 | 13.6 | 6.8 |

| MDS403 | 300 | 510 | 150 | 75 | 51 | 25.5 | 20.4 | 10.2 |

| MDS404 | 400 | 680 | 200 | 100 | 68 | 34 | 27.2 | 13.6 |

Advantages of Inner Inlet Mesh Grille

The dirt is trapped on the inner side of the stencil, backwash is carried out when the stencil is running at the top, and the entrapment enters the slag collection system, which can effectively remove 1-6mm fibers and other solids.

The main components of the equipment are made of non-metallic materials, so the equipment is light in weight, wear-resistant and corrosion-resistant, and can effectively intercept fibrous substances in the water, and 99% of the substances larger than the aperture can be effectively intercepted. The phenomenon of overturning will not cause secondary pollution. The installation of the whole machine does not require pre-embedding of civil works, and there are no transmission parts underwater, so maintenance and maintenance do not require water interruption.

Scope Of Application

This series of products is a very reliable decontamination filtration mechanical equipment with stable operation effect and excellent performance in municipal sewage treatment and water supply treatment, various industrial sewage treatment, and other applications in the field of solid-liquid separation.

This series of products can continuously and automatically remove the solid suspended solids in the filtered water body during operation, which can not only remove the wooden wedges, branches, plastic products and other floating objects in the water body, but also effectively remove the hair and fibers in the filtered water body. It is an ideal high-efficiency pretreatment equipment for water supply and drainage systems. It has been widely used in the fields of sewage treatment, reclaimed water treatment, industrial wastewater treatment, water intake of water supply plants, and industrial water intake of power plants.

Process Effect

Parameters

| Model | DS Standard Capacity(kg/h) | Sludge Treatment Capacity(m³/h) | ||||||

| Low Concentration | High Concentration | 2000mg/L | 4000mg/L | 10000mg/L | 20000mg/L | 25000mg/L | 50000mg/L | |

| MDS101 | 3 | 6 | 1.5 | 0.75 | 0.6 | 0.3 | 0.24 | 0.12 |

| MDS131 | 6 | 12 | 3 | 1.5 | 1.2 | 0.6 | 0.48 | 0.24 |

| MDS132 | 12 | 24 | 6 | 3 | 2.4 | 1.2 | 0.96 | 0.48 |

| MDS201 | 12 | 20 | 6 | 3 | 2 | 1 | 0.8 | 0.4 |

| MDS202 | 24 | 40 | 12 | 6 | 4 | 2 | 1.6 | 0.8 |

| MDS301 | 30 | 60 | 15 | 7.5 | 6 | 3 | 2.4 | 1.2 |

| MDS302 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS303 | 90 | 180 | 45 | 22.5 | 18 | 9 | 7.2 | 3.6 |

| MDS351 | 60 | 120 | 30 | 15 | 12 | 6 | 4.8 | 2.4 |

| MDS352 | 120 | 240 | 60 | 30 | 24 | 12 | 9.6 | 4.8 |

| MDS353 | 180 | 360 | 90 | 45 | 36 | 18 | 14.4 | 7.2 |

| MDS354 | 240 | 480 | 120 | 60 | 48 | 24 | 19.2 | 9.6 |

| MDS401 | 100 | 170 | 50 | 25 | 17 | 8.5 | 6.8 | 3.4 |

| MDS402 | 200 | 340 | 100 | 50 | 34 | 17 | 13.6 | 6.8 |

| MDS403 | 300 | 510 | 150 | 75 | 51 | 25.5 | 20.4 | 10.2 |

| MDS404 | 400 | 680 | 200 | 100 | 68 | 34 | 27.2 | 13.6 |

Factory Site

Package&Delivery

Compay Profile

Since 2017, Biocell has gradually developed from a small mill that produces mbbr bio meida and auxiliary materials including mbbr coarse bubble diffuser and media retention screen to a large-scale innovative factory, which has independent R&D and production capacity for mbbr integrated wastewater treatment plant. The factory covers an area of 10,000 square meters. , The construction area is up to 25,000 square meters, and there are more than 100 employees at present.

Wuxi BioCell Environmental Technology CO., Ltd. is a professional moving bed biofilm reaction system supplier that is mainly engaged in the R&D of MBBR technology equipment, production, and affiliated sales and services.

The main products include Mbbr integrated sewage treatment plant; MBBR suspended bio filter media; Mbbr coarse bubble diffuser and Mbbr media retention screen/seive.

Customer Photo

|