| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Induction Heat Treatment Machine |

|---|---|

| Brand Name: | GY |

| Model Number: | GYS-160AB |

| Certification: | CE, FCC, SGS, ROHS |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 500 sets per month |

| Delivery Time: | 5-8 workdays after payment |

| Packaging Details: | wooden boxes |

| Product Name: | Induction Heat Treatment Machine |

| Heating Materials: | Stainless Steel |

| Warranty: | 1 Year |

| Technology support: | All life |

| After-sales Service Provided: | Engineer On-site Service, Online Support, Video Technical Support |

| Work time: | Non stop, 24 hours a day |

| Features: | Energy saving, safer, more efficient, environmentally, |

| Application: | Online Annealing |

| Company Info. |

| Guangyuan Technology (HK) Electronics Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

160KW Induction Heat Treatment Machine For Multi-Heating Methods

WHAT IS INDUCTION HEATING:

Induction heating is a fast,efficient,precise and repeatable heat treatment method for heating metals or other electrically-conductive material.Material is a metal such as steel,iron,brass,aluminum,alloy,copper,stainless steel,tungsten,nickel,precious metals,silver,zinc,gold and etc.or be semiconductor such as silicon carbide,carbon or graphite.

Quick Detail:

| Name | 160KW Induction Heat Treatment Machine For Multi-Heating Methods | Application | Induction heating |

| Work power | 340V-430V | Out power | 160KW |

| Product size | main : 1000x695x1100mm | Certificate | CE,SGS |

| transformer : 870x430x750mm |

Specification

| Model | GYS-160AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 240A |

| Output power | 160KW |

| Fluctuating frequency | 10-50KHZ |

| Output current | 400-6500A |

| The flow rate of cooling water | 0.08-0.16Mpa 15L/Min |

| Water temperature protection point | 50C |

| Product size | main : 1000x695x1100mm |

| transformer : 870x430x750mm | |

| Net weight | main : 155kgs |

| transformer : 95kgs |

Advantages of induction heat treatment machine:

1. Fast heating: the minimum rate of heating is less than 1 second (rate of heating is available for adjustment and control).

2. Wide coverage of heating: it can be used to heat various metal parts (replace removable induction coil as per different operating switches).

3. Easy installation: it can be used once it is connected with power source, induction coil as well as water supply pipe and rising pipe; it is small in size and light in weight.

4. Easy operation: you can learn to operate it within several minutes.

5. Fast start-up: it can be started to perform heating operation on condition that water and power supply is available.

6. Low power consumption: As compared with conventional vacuum tube high frequency equipments, it can save the power by approximately 70%. The smaller the size of the work piece is, the lower power consumption would be.

7. High effectiveness: it has such features as uniform heating (it is applicable to adjust the spacing of the induction coil to ensure the appropriate temperature as required by each part of work piece), fast warming and limited oxic horizon, and can guard against any waste after annealing.

8. Comprehensive protection: it has such functions as overpressure, over-current, overheat and water shortage alarm indications as well as automatic control and protection.

9. Controllable temperature: it is applicable to control the temperature for heating work pieces as per the preset heating time, and thereby control the heating temperature at a certain technical point.

10. Comprehensive full load design: it can work continuously for 24 hours.

11. Small size and light weight: it has a weight of only several dozens of kilograms, of which, the limited floor space can effectively save the workshop space.

12. Elimination of high voltage: it requires no step-up transformer which may produce approximately ten thousand voltage, and thus can ensure the maximum safety.

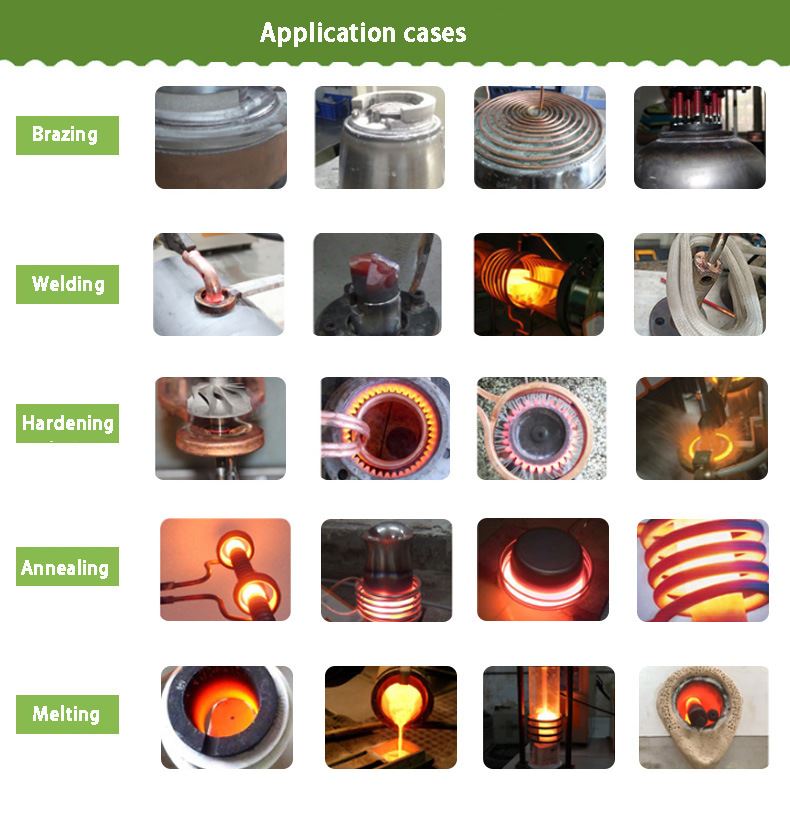

APPLICATIONS FILED:

Tubing wires and cables: Induction welding, induction annealing/ normalizing

Aviation Industry and Automobile Industry: Induction brazing and induction curing bonding

Oil and gas Shibuilding industry: Induction straightening, use induction heating to remove paint and coating

Matallurgy and foundry: Forging and Melting

Generator motor and Pump: Induction Pre-heating and Induction Bolt Heating

ABOUT GY

GY Induction has been engaged in manufacturing of induction heating machine for 27years. At present, there are currently more than 10,000 GY induction heating machines working all over the world. GY induction heating machines are widely used in mechanical forging heating processing, industrial heat treatment manufacturing, tool induction brazing manufacturing, and other fields. Based on the principles of induction technological updates and customers' need, GY induction heating has always been strving to produce industrial induction heating machines with GY Induction Heating's own characteristics and independent core technologies in the induction heating industry. With the upgrading of induction heating equipment from generation to generation, as well as our rich experience in induction heating industrial applications, we serve end customers with high quality industrial induction heating machines all over the world. Taking "win-win with customers" as our value foundation, GY Induction Heating, with our complete R&D designs, project solutions, production team, and after-sales support, are looking forward to cooperating with you.

|