| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Precision Casting |

|---|---|

| Brand Name: | NBSJ |

| Model Number: | SJ7292576 |

| Certification: | TS 16949 and ISO 9001 |

| Place of Origin: | China |

| MOQ: | 1000-5000pcs |

| Price: | negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 3,0000-50000pcs per month |

| Delivery Time: | 10 working days after received your payment |

| Packaging Details: | Packed with anti-corrosion rust paper and bubble paper to pretension ,big rust big and wood box and stick the label |

| Product Name: | Stainless Steel CNC Precision Machining Parts |

| PROCESS: | investment casting and machining |

| Tolerance of rough casting: | ISO8062 CT4-CT6 |

| Standard: | TS 16949 and ISO 9001 |

| Application: | Industrial |

| Weight: | 0.03-0.6KG |

| Material: | 1.4016 |

| Used For: | Auto |

Custom High Quality Stainless Steel CNC Precision Machining Parts

The Stainless Steel CNC Precision Machining Parts is made of 304

stainless steel, which is easy to weld, has high rust resistance in

extreme environments, and capability not to deform with time.

We not only provide various stainless steel exhaust castings, but

also provide a complete exhaust solution. For your standardized

design, no matter what your motivation, we can provide you with an

absolutely awesome exhaust system, which is superior to the so

-called competitors.

Advantages of Stainless Steel Casting

Reliable process controls and repeatability

Design and casting versatility

Surface: very smooth finish

Tight tolerances

Efficient production

Affordable tooling

Material variety

| Product name | Stainless Steel CNC Precision Machining Parts |

| Material: | Stainless steel, |

| Investment casting | lost wax casting,Stainless steel casting,Alloy steel casting,Carbon steel casting,Bronze and Brass casting,Aluminum casting |

| Machining | Drilling, Reaming and tapping,CNC Turning machining,CNC Milling machining,Wire EDM |

| Heat treatment | Annealing,Solution,Normalizing,Tempering,Quenching,Induction hardening,Hardening and tempering |

| Surface treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Stainless Steel CNC Precision Machining Parts

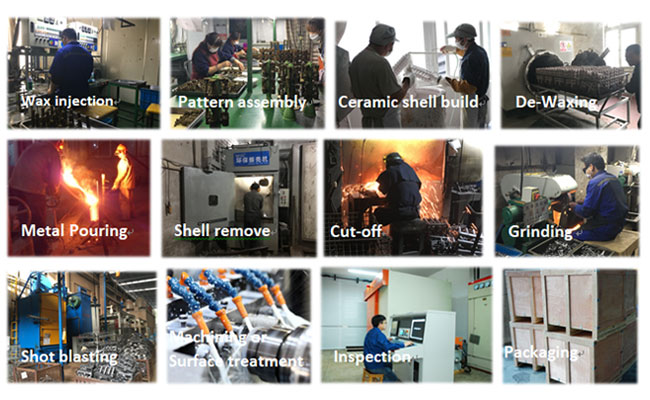

Our invertment precision casting

Process flow:

Wax Injection--Make Wax pattern and repair--Inspection--Shell

Making--De-waxing--Roasting Shell and Melting Steel--Composition

Inspection--Pouring--De shelling--Cutting and Grinding the pouring

gate--Inspection--Heat

treatment--Shotblasting--Machining--Anti-Corrosion--Final

Inspection--Shipping

Precision Casting Part Packing

Our Company

Our

Precision Casting Manufacturing Process

|