| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Industrial Machine Knives |

|---|---|

| Brand Name: | Passion |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | USD 50-70/pcs |

| Payment Terms: | TT in Advance |

| Supply Ability: | 1000 PCS per month |

| Delivery Time: | 5-10days |

| Packaging Details: | carton packing |

| Product name: | industrial machine knives |

| Video inspection: | Yes |

| Machine type: | High speed machine |

| Supplier type: | Final manufacture |

| Production capacity: | 1000-1500pcs/Month |

| Shipping: | Air Express/Sea cargo |

| Blades Grade: | YG12X |

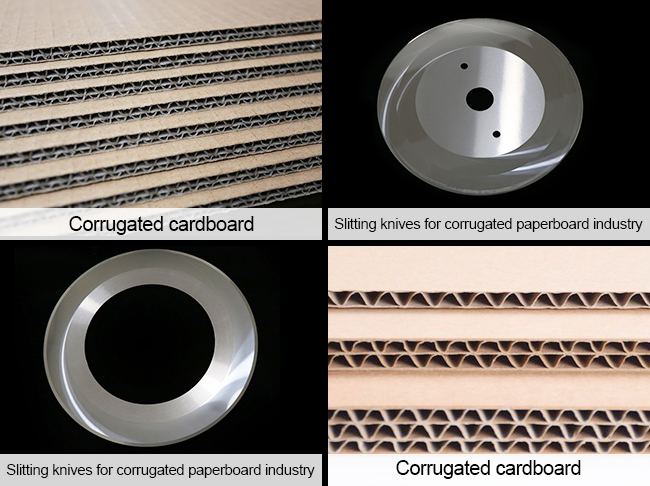

Corrugated Carton Slitting Knife High Precision Tools Razor Slitter Blades

"Passion" tungsten carbide precidion cutting blade has been widely used by various industries.

As one of the private tungsten carbide manufacturers who have its own independent industrial park ,we've been devoting ourselves to creating a trustworthy brand by customer in the first place.We provide not only excellent tungsten carbide products,but also precision cutting tool.

Widely used for slitting corrugated board in domestic and oversea machines or production lines.

---- This kind of knives is made by best pure tungsten carbide raw material.

---- The cutting edge is very sharp, flatness and high precision degree.

We manufacture carbide razor slitters for the following corrugated paper making machine: Agnati, Fosber, Isowa, Marquip, Peters etc.

Specification

| material | This product is produced by using YT/YG series primary cemented carbide blanks, using a combination of tungsten carbide, spherical cobalt powder and carbide particle size and ratio. This can ensure the sharp edge of the knife, good cutting effect and long service life. The problem of frequent replacement of traditional blades is well improved, thereby improving equipment efficiency. |

| Flatness | 0.003mm, or customer customize |

| TYpe of edge | Sharp edge, high hardness, good toughness |

| HRA | 85-93 HRA |

| Surface roughness | Ra0.2 |

| Laser engraving | Done as requirement |

| Merits | |

| Package | step 1, wrapped carbide blades in paper to avoid carbide blade be

broken step 2, put the carbide blade in inner small carton box step 3, put the inner box into outer carton and fill the carton with foamed plastic step 4, wrap the carton with packaging tape |

| Shipping | BY fedex, DHL, TNT, or by sea shipping with big bulk |

| Specification for optional: | Φ230*Φ110*1.3, Φ230*Φ110*1.1-6*Φ9, Φ220*Φ115*1.0-3*Φ9,

Φ240*Φ32*1.2-2*Φ8.5, Φ240*Φ32*1.3-2*Φ8.5, Φ240*Φ115*1.0-3*Φ9, Φ250*Φ150*0.8, Φ257*Φ135*1.1, Φ260*Φ140*1.5-6*Φ9, Φ260*Φ168.3*1.2-8*Φ10.5, Φ260*Φ168.3*1.3-8*Φ10.5, Φ270*Φ168.3*1.5-8*Φ10.5, Φ291*Φ203*1.1-6*Φ8.5, Φ300*Φ112*1.2-6*Φ11 |

| Production | To ensure the quality and the requirements of the drawings can be

met before mass production 1st:, Start to prepare the RTP powder as per customer’s requirement with our wet-grinding machine 2nd, Before mass production, do a trial pressing and sintering using mould, 3rd, Check the appearances and the sizes of the samples with micrometer, projectors etc. |

| Testing | 1st,Mass production press the raw materials to shape blanks, Notes: all carbide blades blanks must be passed by semi finished inspection 2nd,Sinter blanks to finish (HIP) and finished products inspection, Notes:10 sets of vacuum sintering furnace and 2set of HIP in the factory ensure the best quality and production capacity. 3rd,Cleaning/tumbling to make the carbide blades clean and nice surface. |

| Application | Suitable for corrugated paperboard machines,like Fuli, TCY, Fosber, Mitsubishi, K&H, Marquip, Isowa, Oranda, Peters , BHS, Agnati, Justu and etc |

Advantage

The cutting surfaces of razor blades are mirror polished to reduce

the work friction, extending the lifetime

of the blade and reducing the noise level during cutting.

1. Higher quality level.

2. Competitive prices level.

3. Maximum blade lifetime is 16 million meters.

4. Higher mirror finish (Ra = 0,02 µm).

5. Each blade is separately packed.

Company profile

Packing

FAQ

1. How can I get the sample to check your quality?

After price confirmation, you can require for samples to check our product’s quality. If you just need a blank sample to check the design and quality. We will provide you sample for free as long as you afford the express freight.

2. How can I get the price?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please tell us in your email so that we will regard you inquiry priority.

3. What is your term of delivery?

We accept EXW, FOB Shenzhen or FOB Guangzhou. You can choose the one which is the most convenient or cost-effective for you.

* We are here to waiting for you, Please do not hesitate to contact us.

|