| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

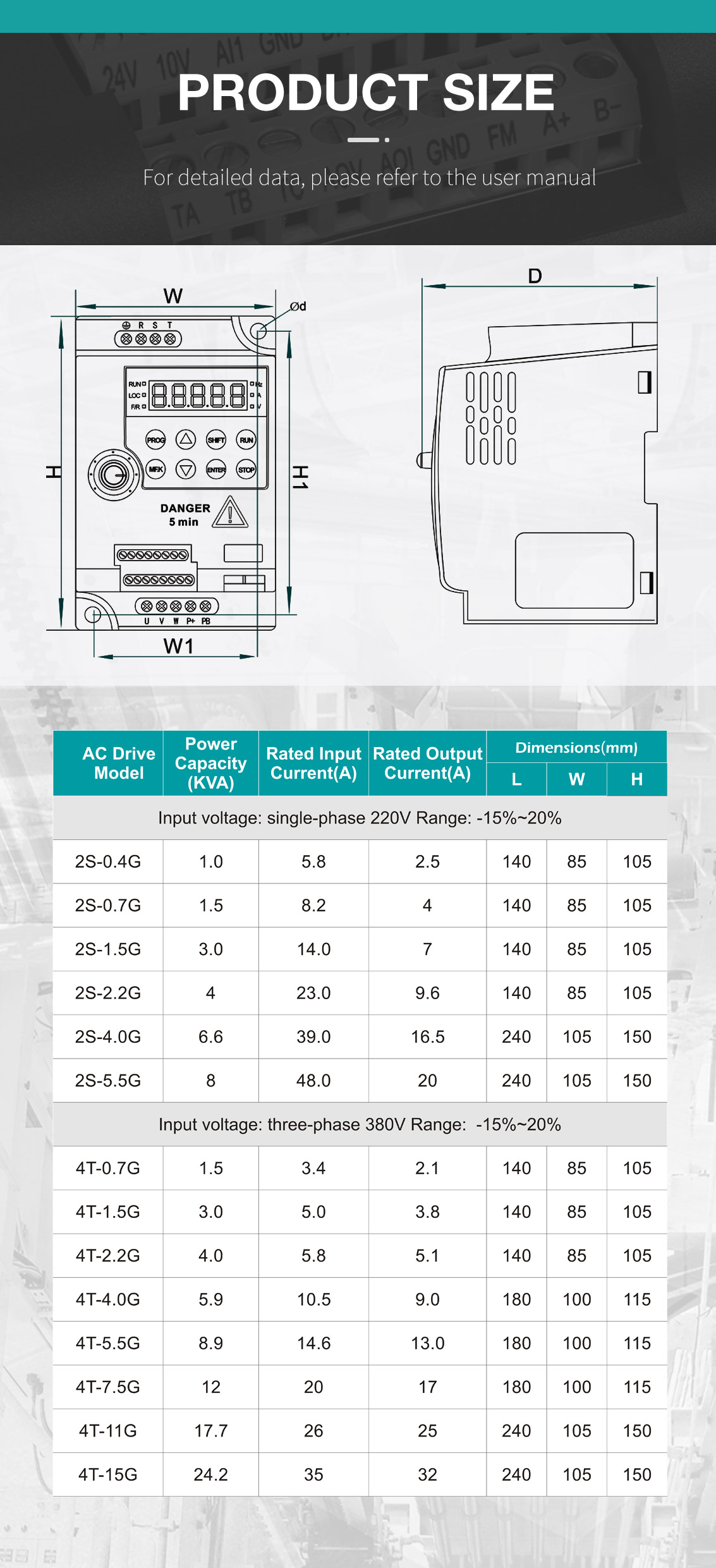

| Categories | Single Phase Inverter |

|---|---|

| Brand Name: | K-Drive |

| Model Number: | KD100 |

| Certification: | CE And ISO Certificated |

| Place of Origin: | China |

| MOQ: | 1pcs |

| Price: | 35USD ~ 300USD |

| Payment Terms: | L/C, D/A, D/P, Western Union, T/T, MoneyGram |

| Supply Ability: | 30000 Sets Per Month |

| Delivery Time: | 1~7 Days |

| Packaging Details: | Carton Box /Woody Box |

| Name: | 7.5kw 10hp Vfd |

| Power: | 7.5kw/10hp |

| Voltage: | 220v/380v |

| Frequency: | 0-2000HZ |

| Protection: | Overload,Overvoltage,IP20,Short Circuit,over Heat |

| Igbt: | Infineon |

| Highlight: | 10HP Single Phase Motor Vfd Drive, 7.5KW Single Phase Motor Vfd Drive, 10HP Variable Frequency Device |

220V 380v 7.5KW 10HP VFD with vector control ac drive frequency inverter

Product Advantage

1. Our KD-100 series is vector control, it can run very accurately with faults less than 0.5%.

2. It has perfect protection, for example, over voltage, over current protection, especially the groud protection.

3. It has the optimized algorithm which is easy to use, even those who don't have a good knowledge of Vfd also can operate it without any problems.

4. We were also certificated by the European standard, such as the CE, ISO9001.....

5. If all these still can not fullfil the requirement of our customers, we have the excellent R&D team can design the software program according to your requirement.

Thanks to sophisticated engineers, scientific producing workmanship, rigorous quality control systems and management team, K-Drive frequency inverters are equipped with advanced features, some of which are listed as below:

01. Starting torque: 180% at 0.5Hz (V/f pattern, SVC pattern);

02. Speed adjustable range: 1: 100 (V/f pattern, SVC pattern);

03. Speed accuracy: +/-0.5% (V/f pattern), +/-0.2% (SVC pattern);

04. Over load capability: 150% 1minute, 180% 10seconds;

05. Abundant frequency command sources;

06. Diverse input and output terminals;

07. Ambient temperature: -10°C~50°C;

08. High precise torque constraint, process PID control, multi-speed control, contracting brake control, field weakening control, all sides protection, etc;

09. Online and offline auto-tuning of motor parameters can both performed;

10. Extremely short-time acceleration can be performed without any trip, such as 0.1s or 0s from 0Hz to 50Hz;

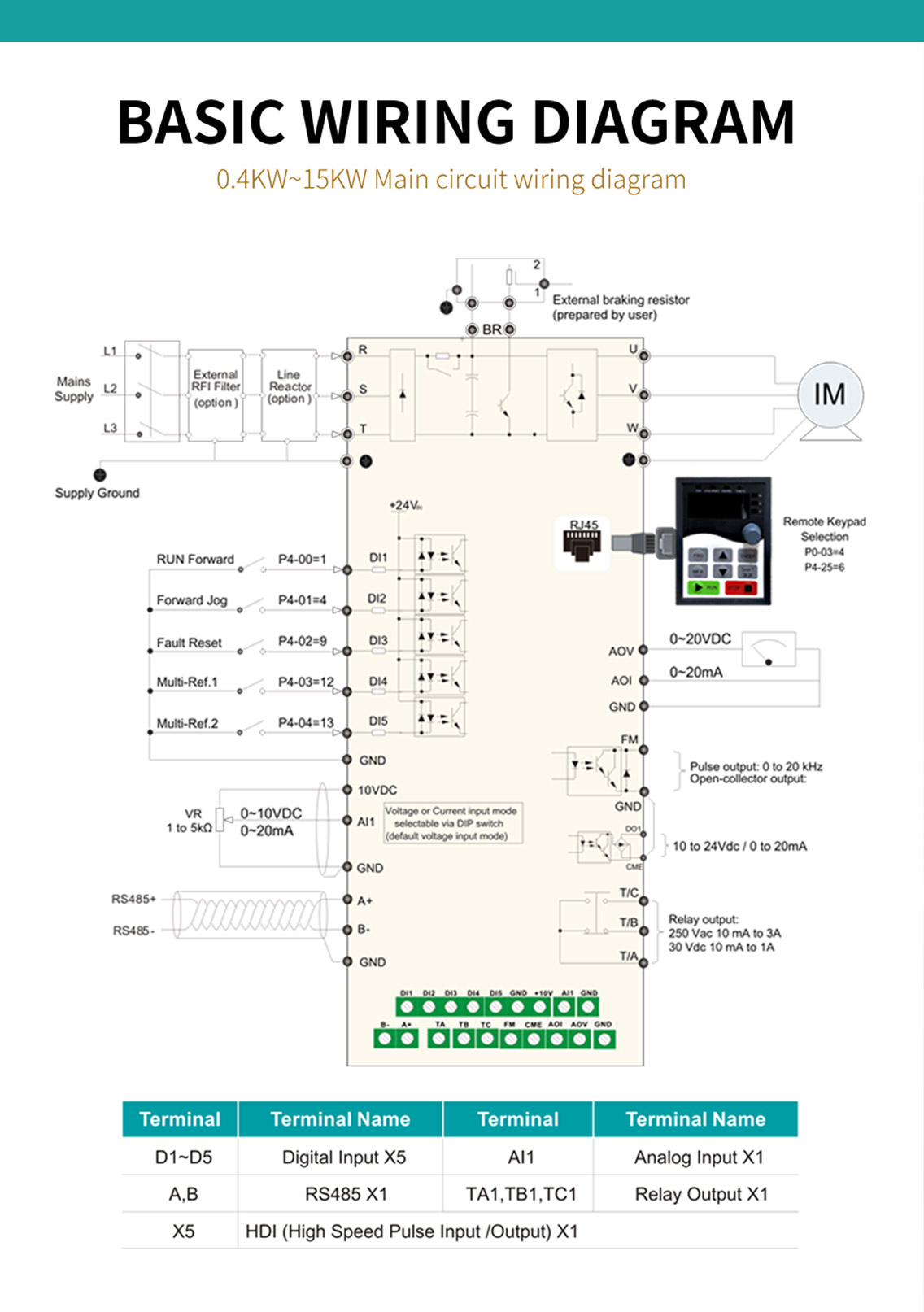

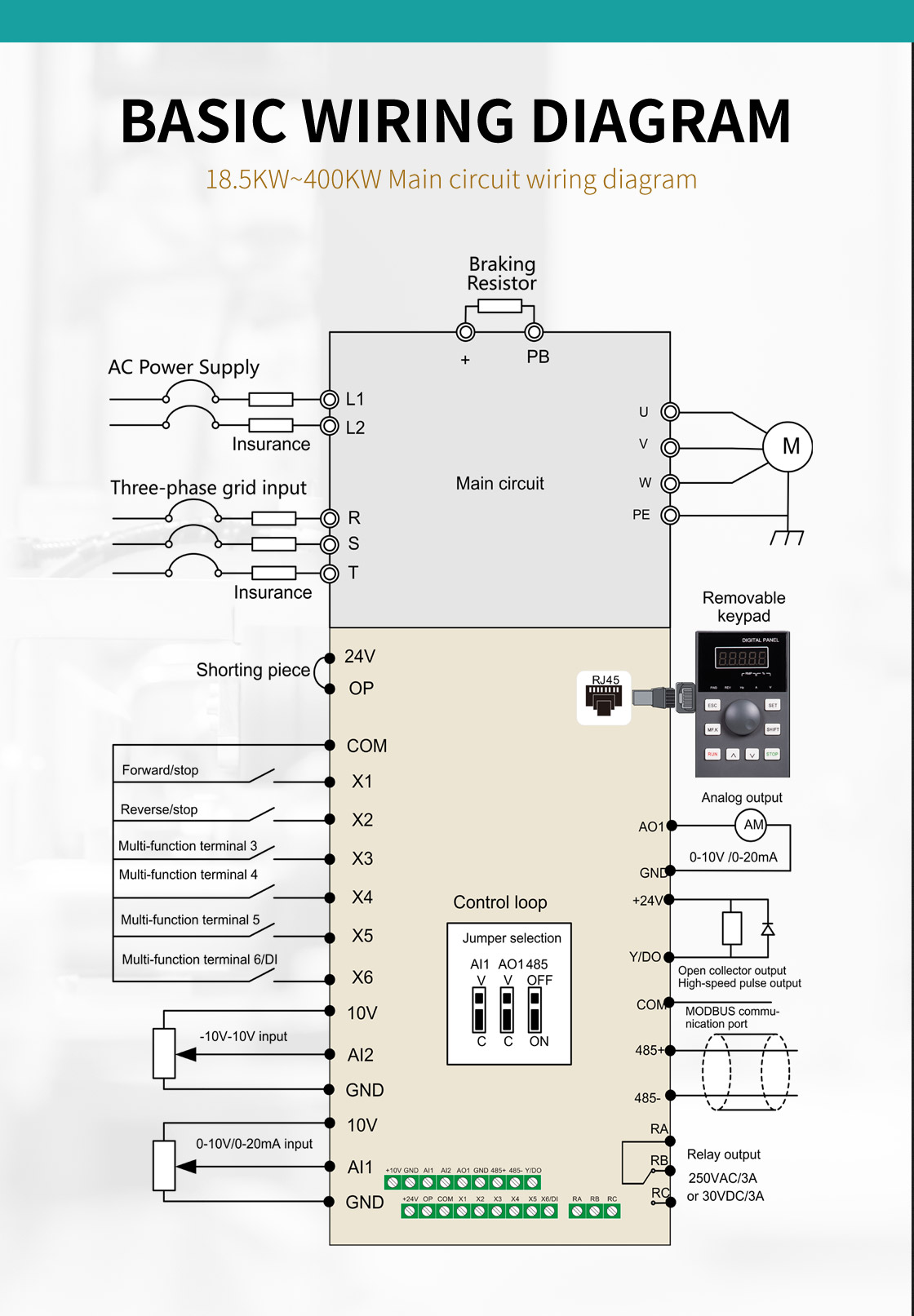

| Mains Supply (L1/L,L2,L3/N) | |

|---|---|

| Supply voltage | 208-240V±10% 380-480V±10% |

| Power source frequency | 50/60Hz±5% |

| Displacement power factor (cos φ) | (> 0.98) |

| Output Data (U, V, W) | |

|---|---|

| Output voltage / frequency | 0-100% of supply voltage / 0.00-600.00 Hz or customized |

| Ramp time | 0.01-60000 S |

Note:150% current can be provided for 1 minute, 180% for 10 seconds. Higher overload rating is achieved by oversizing the drive.

| Digital Input | |

|---|---|

| Programmable digital inputs | 5 |

| Logic | NPN or PNP |

| Voltage level | 22 - 26V |

| Analog Input | |

| Analog inputs | 2 |

| Modes | Voltage or current |

| Level | 0 to +10V, 0/4 to 20 mA (scalable) |

| Automatic correction | YES |

| Relay Output | |

| Programmable relay outputs | 1 |

| RA - RB / TA - TB | Normally close |

| RA - RC / TA - TC | Normally open |

| Contact capacitance | 250VAC/3A, 30VDC/3A |

| Terminal 485 Interface | |

| 485+ / 485- | Rate: 4800/9600/19200/38400/57600/115200 bps Max. distance: 500m |

| GND | Isolated from COM |

| Ambient | |

| Vibration | Less than 5.9 m/s² (0.6g) |

| Humidity | Relative humidity 5% - 95 %. No condensation |

| Corrosive environment | 3C3 |

| Ambient temperature | -10 ºC - 50 ºC |

| Altitude | 0 - 2,000 m |

| Rated output current derated 1% every 100 m above 1,000 m | |

| Storage temperature | -40 - +70 ºC |

| Efficiency | Efficiency At rated amps: ≥93% |

| IP grade | IP20 |

| Cooling method | Forced air cooling |

| Fieldbus Communication | |

| Modbus RTU, Modbus ASCII | Built-in |

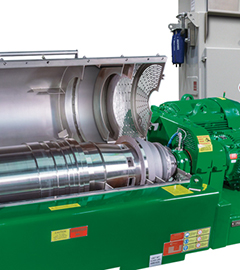

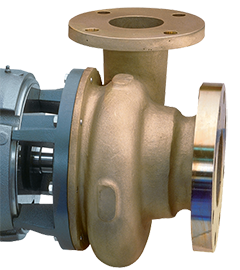

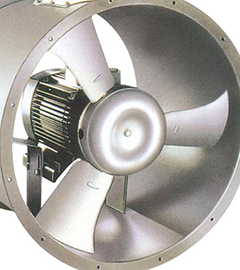

KD100 drives are economical series at K-Drive. They offer V/f control, including voltage and frequency separated control, adaptable to various industrial applications if sensor-less vector control is not required, including printing machines, packaging machines, pumps, fans and blowers, etc.

|  |  |

| Conveyors | Centrifuges | Food processing Machinery |

|  |  |

| Pumps | Fans | More … |

In the trend of advocating smart and simple industrial automation, environmentally friendly products, value-added solutions, K-Drive, as one of the world's leading drive manufacturers aggressively investing in R&D, production, and continuous quality improvement, is well positioned to provide its customers with technology-driven, performance-outstanding products such as VFDs, wind power converters, servo drives, HEV/EV drives, helping its customers save energy and increase industrial productivity with sustainability on the one hand, and enhancing their entire value-chain quality, delivery, and services on the other hand.

In production, rigorous quality control is implemented on components, circuit boards, and the finished goods, assuring products without defects.

| Performance | Common brands | K-Drive |

|---|---|---|

| Applicable motors | Asynchronous motors | Asynchronous /synchronous motors |

| Starting torque | 2.0Hz, 150% (sensor-less vector control) 0Hz, 180% (closed-loop vector control) | 0.5Hz, 180% (sensor-less vector control) 0Hz, 200% (closed-loop vector control) |

| Speed adjustable range | 1:100 (SVC), 1:1000 (VC) | 1:200 (SVC), 1:1000 (VC) |

| Ambient temperature (no derating required) | -10-40ºC | -10-50ºC (for most of the models) |

| Rated input voltage | 208VAC-400VAC | 208VAC-480VAC |

| Communication | Modbus RTU//ASCII | Modbus RTU//ASCII Profibus-DP, CANopen, etc. |

| Position control (fixed length, or angular positioning) | × | √ |

| Field weakening control | × | √ |

| Autotune online | Online | Online & Offline |

| Short-time ramp-up | Trip | No trip |

| Customized features (software and/or hardware) | Unprocurable or no experience | Procurable with rich experience |

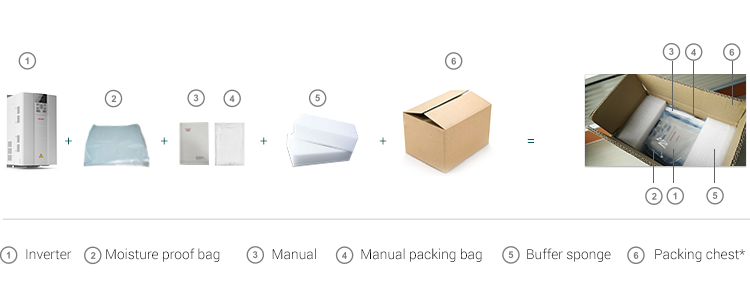

All drives are well packed before shipment, fit for air shipment, sea transportation, and express delivery. Customers are able to call its own nominated forwarder or consult K-Drive logistics department for worldwide shipment services.

* Low-power inverters are packed in cardboard box, and others are in plywood cases.

* Plenty of transportation procurable globally in accordance with customer demand or K-Drive expertise.

Please leave us an inquiry for more details of our frequency inverters, like information of the model numbers, technical data, applicable application, pricing, distributor policy, lead time and/or customized functionality.

Check the VFD specifications: The first step in assessing a VFD is to review its specifications, including its input voltage, output voltage, frequency range, rated power, and protection features.

Verify the wiring connections: Ensure that the VFD is correctly wired and grounded to prevent electrical hazards.

Test the VFD functionality: Test the VFD by applying a load to the motor and observe how the VFD responds to different speed and torque settings. Verify that the VFD can operate within its specified range without overheating, tripping, or generating excessive noise.

Check the safety features: Verify that the VFD has safety features, such as overcurrent protection, overvoltage protection, and overload protection, to prevent damage to the motor and the VFD itself.

Inspect the VFD enclosure: Ensure that the VFD enclosure is clean and free from debris that can block airflow and cause overheating. Also, verify that the VFD has adequate ventilation and cooling.

Verify the VFD programming: Check the VFD programming to ensure that it is correctly set up and configured for the intended application. Verify that the VFD has been programmed with the correct motor parameters, such as motor type, horsepower, and operating frequency range.

Record the assessment results: Keep a record of the VFD assessment results, including any issues found, and recommend any necessary corrective actions.

Overall, assessing a VFD requires careful attention to detail and a good understanding of VFD operation and safety features. It is essential to follow the manufacturer's instructions and guidelines to ensure a safe and accurate assessment.

|