| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Automatic Blowing Machine |

|---|---|

| Brand Name: | Eceng |

| Model Number: | YCQ-2L-4 |

| Certification: | CE&ISO&SGS |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | 25000-35000USDper set |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 10sets per month |

| Delivery Time: | 20workingday |

| Packaging Details: | film packing |

| cavity: | 4 |

| capacity: | 4000 |

| PLC: | Mitsubishi |

| cylinder: | SMC |

| Electric parts: | Schneider |

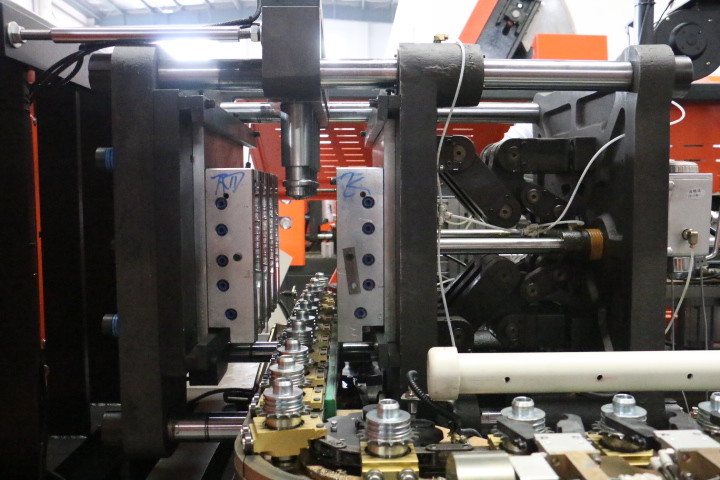

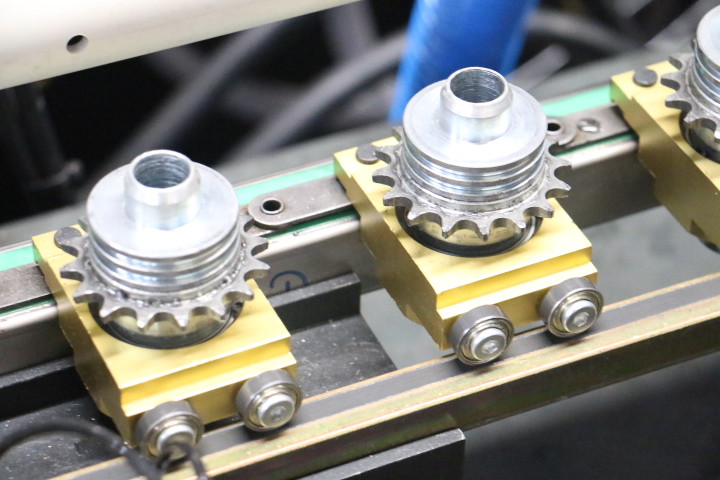

Factory making machine-Automatic PET plastic

Bottle Blowing Machine

| Model | YCQ-2L-2 | YCQ-2L-3 | YCQ-2L-4 | |

Bottle type specification | Cavity | 2 | 3 | 4 |

Theory output | 2400-2700 | 3500-4000 | 4500-5000 | |

| Max.volume | 2L | 2L | 2L | |

Bottle mouth maximum overall diameter | 80mm | 28-38mm | 28-38mm | |

Bottle biggest diameter | 100mm | 100mm | 100mm | |

Bottle maximum height | 330mm | 330mm | 330mm | |

Power specifications | Light tube quantity | 32pcs | 32pcs | 32pcs |

Light tube power | 0.75KW | 1.25KW | 1.25KW | |

Maximum heating power | 24KW | 40KW | 40KW | |

All electric machine installation | 27KW | 43KW | 43KW | |

Actual consumption | 8.1KW | 21.5KW | 21.5KW | |

Air pressure specification | Work pressure | 7-9kg/c㎡ | 7-9kg/c㎡ | 7-9kg/c㎡ |

Low-pressure gas consumption | 1000L/min | 1600L/min | 1600L/min | |

Blow bottle pressure | 25-35kg/c㎡ | 25-35kg/c㎡ | 25-35kg/c㎡ | |

Higher -pressure gas consumption | 1500Ltr/min | 2500Ltr/min | 3000Ltr/min | |

Forzen water specification | Work pressure | 5-6 kg/c㎡ | 5-6 kg/c㎡ | 5-6 kg/c㎡ |

Temperature range | 10℃ | 10℃ | 10℃ | |

Consumption | 5000kcal/hr | 8000kcal/hr | 8000kcal/hr | |

Forzen water flow | 30L/min | 88L/min | 88L/min | |

Machine specification | Size of the machine | 2.25x1.6x1.7 | 4.0x1.6x1.9 | 4.5x1.6x1.9 |

Weight of the machine | 2.5ton | 3ton | 3.5ton |

1. Reply the email and take action in 24 hours;

2. 100% Quality inspection before the shipment;

3. Can trainning clients operator for free in seller`s factory

4. Engineer overseas is avilable

5. Blowing mould and injection mould made orginal

6. Auxiliary machines for complate line.

7.Custimized design as requirements.

|