| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Plastic To Diesel Machine |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-10TPD |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 35000-65000/set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 220 sets per year |

| Delivery Time: | 15 days |

| Packaging Details: | Nude packing |

| Raw material: | waste plastic and tyres |

| Type: | Batch type |

| Cooling method: | circle water cool |

| Output product: | Fuel oil , Carbon black , Steel wire, gas |

| Heating fuel: | Wood /Coal /Gas /Oil |

| Voltage: | 380V |

| Capacity: | 1-15ton per batch |

| Internal volume: | 40.6 m³ |

| Rotating speed: | 0.4 turn/minute |

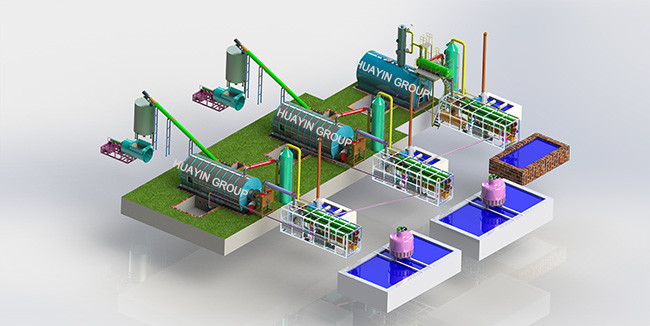

Pyrolysis Plant And Refinery Pyrolisis Plastic To Gasoline And Diesel

The Function of the Waste Plastic Pyrolysis Machine

The bulk of the plastics we use—the candy wrappers, stand-up

pouches, potato chip bags, protective packaging, single-use cups,

frozen food bags are constructed from multiple plastics that are

nearly impossible to separate. At this time the pyrolysis plant is

a good choice for recycling the waste plastic. By using the waste

plastic pyrolysis machine , we can get plastic pyrolysis oil and

carbon black.

Working process of waste plastic pyrolysis system machine :

Step 1 . Put the raw material into the pyrolysis reactor . Huayin offers auto feeder machine to help feeding , saving time and labour.

Step 2. Heat the pyrolysis reactor. When the temperature reaches to 300-600 degrees , a large amount of oil and oil gas will be produced. The oil will be collected into the oil storage tanks.

Step 3. Dedusting . During the pyrolysis process , the black smoke will be purified by the ceramic packing dedusting device which can filter the smoke effectively., thus the smoke meets the emission standards. We also have other designs for the dedusting system, customers can choose according to their budget and local emission standard.

Step 4. Discharge carbon black and steel wire. The carbon black will be discharged out by screw conveyor discharger with water cooling jacket , allows discharging at a high temperature.

Parameter of Huayin Pyrolysis Machine

| Model | HY-05 | HY-08 | HY-10 | HY-15 | HY-30 |

| Capacity | 5 t/d | 8 t/d | 10 t/d | 15 t/d | 30-35 t/d |

| Working Type | Batch | Batch | Batch | Batch | Continuous |

| Reactor size(m) | D2.2*L5.5 | D2.6*L6.6 | D2.8*L6.6 | D2.8*L8.1 | D1.2*L24 |

| Reactor material | Q245R | Q245R | Q245R | Q245R | 310S stainless steel |

| Power | 29.4KW | 29.4KW | 32KW | 34KW | 100KW |

| Heating Fuel | Pyrolysis oil /coal/ wood/natural gas | ||||

| Burners | 3*300,000 kcal | 3*300,000 kcal | 3*300,000 kcal | 4*300,000 kcal | 12*30000kcal |

| Working pressure | Normal | Normal | Normal | Normal | Normal |

| Landing Area | 200m2 | 250m2 | 300m2 | 350m2 | 700m2 |

| Number of Containers | 1*40FR+1*40HQ | 1*40FR+2*40HQ | 1*40FR+2*40HQ | 1*40FR+2*40HQ | bulk cargo |

| Noise (dB) | ≤60 | ≤60 | ≤60 | ≤60 | ≤60 |

| Cooling Mode | Circle Water | Circle Water | Circle Water | Circle Water | Circle Water |

Advantages of Huayin Plastic to Fuel Pyrolysis System

1. High automation: Loading used tires/plastic into the pyrolysis reactor with 50ton hydraulic pressure, so the auto feeder can help you save labor and load more waste raw material, compared with manual feeding, the automatic feeder is more efficient.

2. 100% safety: The pyrolysis reactor is made of Q245R/Q345R boilerplate, which is high pressure and high-temperature resistance that ensure its longer service life. Adding perfect hot seal technology to ensure operation safely.

3. Environmental friendly: Flue gas is purified by ceramic packing dedusting device, finally no black smoke emitted.

4. High efficiency discharging device: Discharge carbon black from pyrolysis reactor after the production is finished in a sealed condition, no pollution and saves labor and time.

5. Strictly quality control. All of the steel plates are purchased from China's famous company " Anyang Iron and Steel Co., Ltd ", and the raw material inspection certificate can be provided to customers. For each set of machines, we will do ultrasonic nondestructive testing, and automatic submerged welding technology to ensure the machine quality.

Packing and delivery

Packaging details | 1*40FR and 1*40HQ for 10 tons 2*40 HQ for 5 tons Weight: about 30tons All goods are packed with export standard package to make sure no damage during transportation. |

| Detail details | about 15 days after receiving deposit. |

For more details , welcome contact us !

|