| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tungsten Carbide Valve Seats |

|---|---|

| Brand Name: | XYMJ |

| Model Number: | Customized |

| Certification: | ISO 9001:2018 |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 2000 kilograms per month |

| Delivery Time: | 7-15 |

| Packaging Details: | Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton |

| Advantages: | HIP-Sinter/ high accurate |

| Material: | Wc+Co(Ni) |

| Physical Performance: | High Wear Resistance, Corrosion resistance |

| Product Name: | Cemneted Carbide Valve Seat And Ball |

| Free Sample: | Yes |

| Size: | Customized |

Hard Metal Alloy Solid Cemented Tungsten Carbide Valve Seat

Tungsten carbide mechanical seals are being used increasingly on fluid pump to replace packed gland and lip seal. Pump with mechanical seal perform more efficiently and generally perform more reliably for extended periods of time.

According to the shape, those seals are also called tungsten

carbide mechanical seal rings. Due to the superiorities of tungsten

carbide material, Our tungsten carbide mechanical seal rings shows

high hardness, and the most important is that they resist corrosion

and abrasion well. therefore, tungsten carbide mechanical seal

rings are having wider use than seals of other materials.

Specification

1. High strength, high wear resistance, high precision, good

temperature resistance and good corrosion resistance.

2. Mainly used for the sealing of valves of oil pumps in petroleum

industry`s containing wells, viscous oil wells, sea oil wells and

high pressure sulfur resistant oil wells, etc.

3. Balls and seats are used with compatible cemented carbide valve

seats.

4. Precision machined cemented carbide balls of other grades and specifications are also available based on customers` demands.

5. Compatible high precision valve seats can also be made.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

Grade and applicaton for valve seat

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) | Application |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wear-resistant |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Application |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 | Corrosion-resistant |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 | |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 | |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

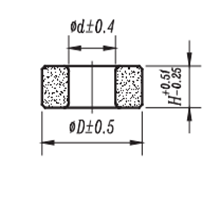

| Seats dimension (mm) | ||

| D | d | H |

| 19.48 | 11.68 | 12.7 |

| 22.66 | 13.97 | 12.7 |

| 28.22 | 17.02 | 12.7 |

| 33.81 | 20.96 | 12.7 |

| 36.09 | 24.38 | 12.7 |

| 41.43 | 26.92 | 12.7 |

| 48.79 | 33.27 | 12.7 |

| 74.93 | 43.18 | 19.05 |

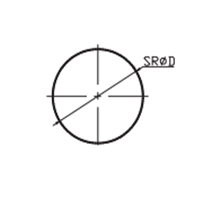

| Ball dimension (mm) | ||

| D±1.27(mm) | ||

| 15.88 | ||

| 19.05 | ||

| 23.83 | ||

| 28.58 | ||

| 31.75 | ||

| 34.93 | ||

| 42.88 | ||

| 57.15 |

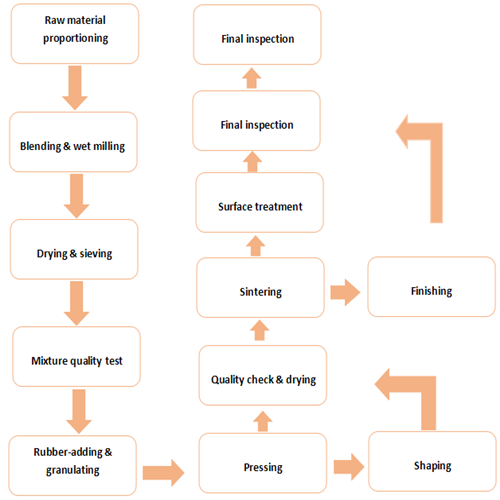

Production Process

FAQ

Q1: Are you trading company or manufacturer ?

A1: We are factory.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is

25-35 days if the goods are not in stock, it is according to

quantity.

Q3: Do you provide samples ? is it free or extra ?

A3: Yes, we could offer the sample for free charge but do not pay

the cost of freight.

Q4: What is your terms of payment ?

A4: Payment<1000USD, 100% in advance. Payment>1000USD, 30%

T/T in advance ,balance before shipment.

|