| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cold Runner Injection Molding |

|---|---|

| Brand Name: | Chitwing |

| Model Number: | Smart Watch |

| Certification: | ISO 9001:2015 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 set/month |

| Delivery Time: | 30 day(s) |

| Packaging Details: | The mold is packaged with a wooden box and placed on a wood pallet. |

| Size: | 350.000 X 450.000 X 391.000 |

| IMM Tonnage: | 180T |

| Mold Weight: | 392kg |

| Mold base P/N: | GCI3045 10011090 |

| Tool life: | 500000 shots |

| Part material: | PC |

| Gate: | Side gate |

| Slide/Lifter: | 2/5 |

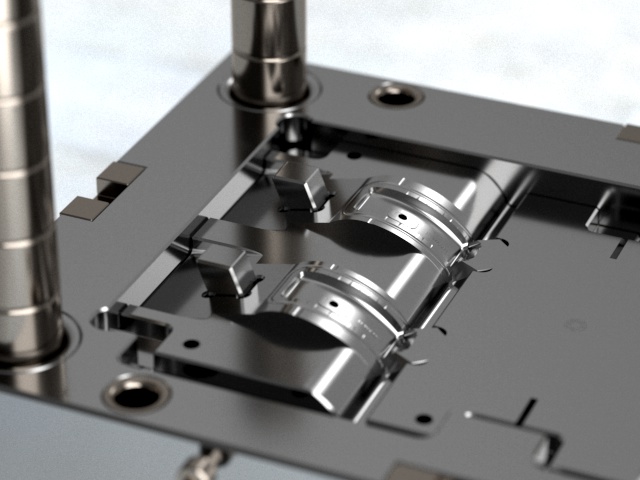

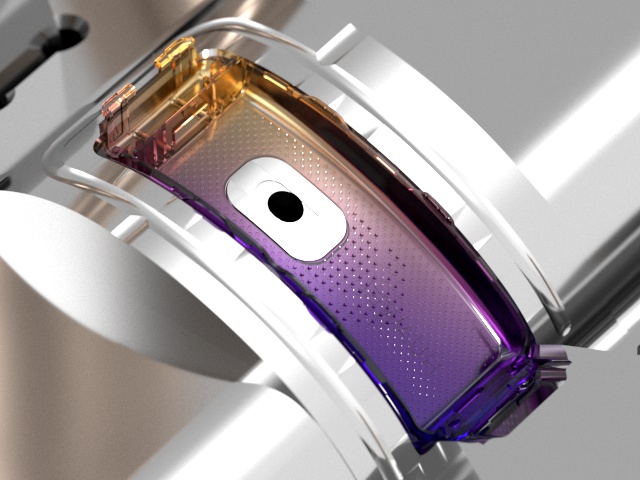

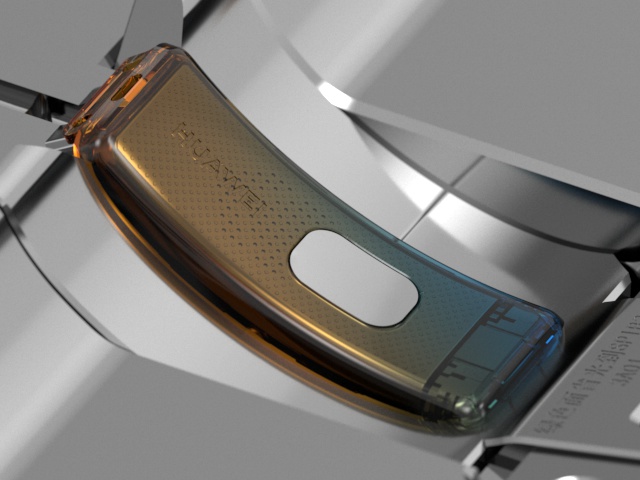

Transparent Smart Watch Base

Lower Housing (1*4)

No.23305

| Mold base P/N | GCI3045 10011090 | |||

| Mold size | 350x450x391 | |||

| Mold net weight | 392kg | |||

| IMM Tonnage | 180T | |||

| Standard | LKM | |||

| Type | Three-plates mold | |||

Tool life : 500K shots

Gate : Side gate

Part material : PC

Part size : 21.41 X 50.40 X 25.18mm

Product net weight : 1.6g

Injection/runner type : Hot runner produces no condensed materials, has a high degree of automation, does not require post-processing, and greatly saves the cost of raw materials and labor | ||||

Surface finish : A surface EDM with SPI-B1 molded part has smooth and clearer surfaces. | ||||

Steel of cavity & core : Harden (1*4/S136) injection molding process, ensure long tool life, and meet requirement of high-quality mass production. | ||||

| Slide | Lifter |

| 2 | 5 |

Display diagram

| Mold base P/N | GCI3045 10011090 | |||

| Mold size | 350x450x391 | |||

| Mold net weight | 392kg | |||

| IMM Tonnage | 180T | |||

| Standard | LKM | |||

| Type | Three-plates mold | |||

| Tool life : 500K shots Gate : Side gate Part material : PC Part size : 21.41 X 50.40 X 25.18mm Product net weight : 1.6g | ||||

Injection/runner type : Hot runner produces no condensed materials, has a high degree of automation, does not require post-processing, and greatly saves the cost of raw materials and labor | ||||

Surface finish : A surface EDM with SPI-B1 molded part has smooth and clearer surfaces. | ||||

Steel of cavity & core : Harden (1*4/S136) injection molding process, ensure long tool life, and meet requirement of high-quality mass production. | ||||

|