| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicone Auto Parts Making Machine |

|---|---|

| Brand Name: | TYM |

| Model Number: | TYM5058 |

| Certification: | CE,ISO9001 |

| Place of Origin: | China |

| MOQ: | »1 |

| Price: | USD 48999-55999 Set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 set year |

| Delivery Time: | 45 workdays |

| Packaging Details: | wooden case |

| Condition: | New |

| After-sales service provided: | Engineers available to service machinery overseas,Online support |

| Power(kw): | 12.1 |

| Automatic: | Yes |

| Opening stroke: | 200-700mm |

| Injection rate: | 30g/s |

| Style: | Horizontal |

| Clamping force: | 130T |

| Machine weight: | 5.3T |

| Machine dimension(l*w*h): | 2.4*1.6*3.4m |

| Product name: | vertical injection molding machine |

| Color: | Green |

| Warranty: | 1 year |

| Ejector stroke: | 150mm |

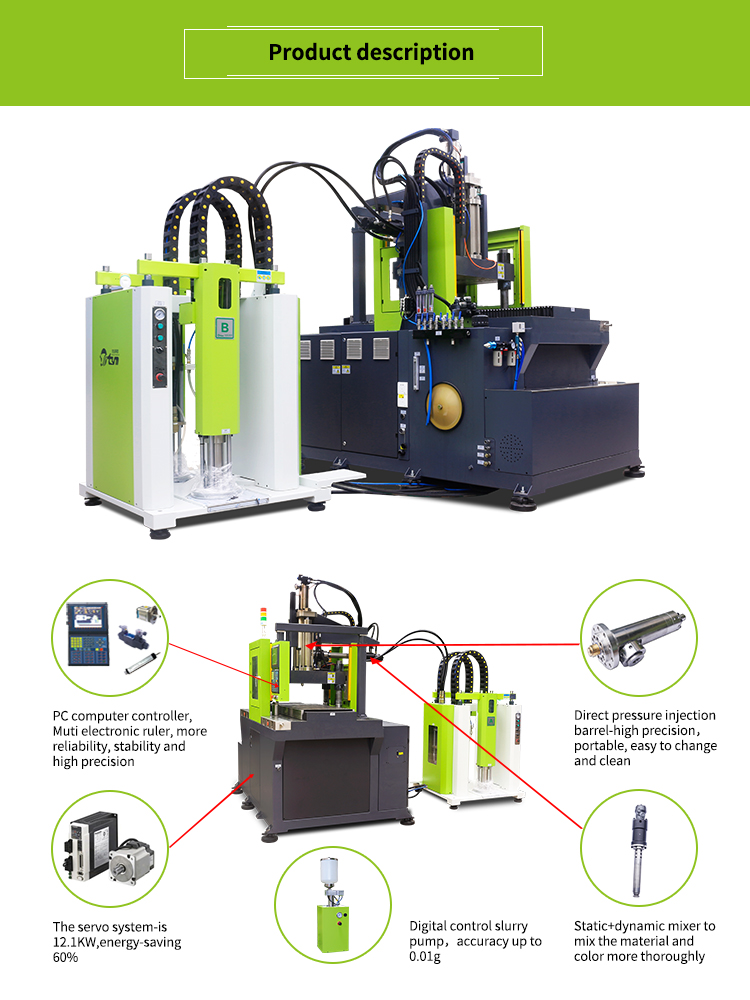

High speed injection molding machine for auto parts/high transparency/high effeciency production process

Silicone rubber is distinguished from other elastomers by the strength of the siloxane bond. Whereas carbon bonds have a binding energy of 355 kJ/mol, the strength of the siloxane bond is 433 kJ/mol. This contributes to its greater heat resistance, chemical stability, and electrical insulation.

At the same time, silicone bonds also feature low intermolecular forces, which means that other chemical groups attached to them can rotate freely. Because of this, liquid silicone rubber possesses material properties such as a high degree of elasticity and compressibility, as well as water repellence and good releaseability.

When choosing materials to manufacture critical parts and components, consider Liquid Silicone Rubber (LSR). LSR is the primary material we process at TYM — as a result, there’s no better partner for your manufacturing needs, and no one more experienced in helping clients make the most of it.

Liquid silicone rubber’s characteristics and chemical properties make it an ideal material for applications spanning several different industry verticals

Mechanical Characteristics for TYM-L5058-2

| TYM-L5058 Vertical LSR injection molding machine | |

| Injection Unit | |

| Shot Volume | 165 g |

| Injection Rate | 30 g/s |

| Injection Pressure | 19.6 T |

| Clamping Unit | |

| Clamping Force | 130 T |

| Opening Stroke | 250-550 mm |

| Tie-Bars Pace | 500*580 mm |

| Ejection Force | 7.8 T |

| Ejection Stroke | 150 mm |

| Others | |

| Pump Pressure | 21 Mpa |

| Motor Power | 12.1 KW |

| Heater Power | 9 KW |

| Mould Orientation Ring Diameter | Φ 100 mm |

| Machine Weight | 5.2 T |

| Machine Dimension | 2.5*1.6*3.6 m |

Our Service & Advantages:

1. Reply your enquiry in 24 working hours.

2. Experienced staff answers all your questions in fluent English.

3. More than 10 years experience to LSR injection molding machine

in China.

4. Tianyuan can design the LSR injection molding equipment

according to the customer's requirements, provide a whole set of

solutions for the LSR equipments.

5. Our LSR injection molding machine is widely used in medical

industry, food industry, infant industry , diving industry,

insulator industry and other LSR production field.

6. According to the high quality, precise and reliable of the LSR

injection molding machine, we help the customer to produce the

refined LSR products and price ratio is in high performance in the

LSR industry.

7. Welcome OEM and ODM.

|