| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Portable Concrete Batch Plant |

|---|---|

| Brand Name: | ENCKE |

| Model Number: | EC25 m³/h |

| Certification: | CE SGS IS9001 |

| Place of Origin: | Mainland |

| MOQ: | 1 set |

| Price: | USD |

| Payment Terms: | T/T, L/C, Western Union, D/A, D/P, MoneyGram |

| Supply Ability: | 100 sets per year |

| Delivery Time: | 20-40 work days |

| Packaging Details: | 1 unit 40’HQ Container along with the bag cement feeding system |

| Item: | Price Mobile Concrete Batch Mix Plant 25m3/h Four Aggregate Bins |

| Aggregate silo: | four aggregate bins |

| Features: | producing concrete just a few hours after the batching plant is installed at the building site |

| Weighing system: | optioanl/cement weighed in concrete mixer |

| Concrete mixer: | planetary mixer or pan mixer |

| Type: | 25m3/h |

| Company Info. |

| Shandong Encke Imp&Exp Co.,LTD |

| View Contact Details |

| Product List |

Price Mobile Concrete Batch Mix Plant 25m3/h Four Aggregate Bins

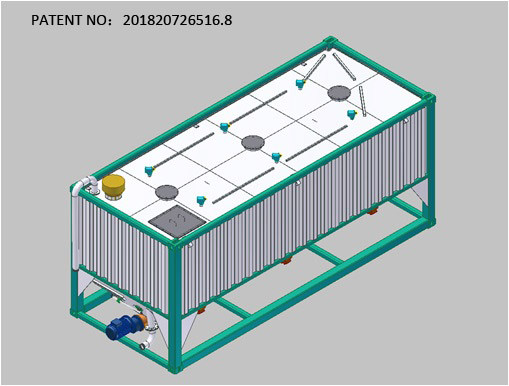

The mobile concrete batch mix plant EC25 is intended for the production of high-quality concrete and concrete mixes in volumes of 20-30 m3 per hour.The plant is designed on a container frame,which can be moved directly .The mobile concrete batch mix plant is compact, well thought-out solutions, designed to provide optimum flexibility.

Starting producing concrete just a few hours after the batching plant is installed at the building site. All you have to do is connect electricity, water and any other equipment, and fill sand and gravel in the hoppers. And when the job is done, just move the plant on to the next job.

The key point is that the mobile concrete batch mix plant is a profitable investment which will soon pay for itself and return a profit. All wearing parts are produced in robust materials and can be replaced separately, which minimises operating costs.

Technical features:

| Max mixing capacity: | 0-30m³ / h | |||

| Total electric power (min-max): | 31-46KW. | |||

| Automatic and manual mixing control | Included | |||

| WEIGHTING SYSTEM | ||||

| Aggregate bins | 2*4m³/4*4m3 | Sand and stone | ||

| Aggregate Weigh Hopper | 0-1000KG | Weighing load cell | ||

| Aggregate Weighing belt conveyor | Belt wide B=800 | |||

| Cement Weighing Capacity | 0-250KG | Weighing load cell | ||

| Water Weighing Capacity | 0-200KG | Weighing load cell | ||

| Additive Weighing Capacity | 0-25L | |||

| MIXER | ||||

| Load capacity | l | 750L | ||

| Mixing capacity | l | 500L | ||

| Pump electric motor | kw | 15 | ||

| AIR COMPRESSOR | ||||

| Delivery | l/min | 330 | ||

| Air tank | l | 100 | ||

| Electric motor | kw | 3 | ||

| RECOMMENDED OPTION | ||||

| Horizontal silos | m³ | 26 | Multi choice | |

| Concrete belt conveyor | m | 12 | Width 800,7.5kw | |

| OPTIONAL | ||||

| Cement silo | 15-100 ton | |||

| Container bag bins | 2m³ | Suitable for container bag | ||

| Additive Weighing system | 25L | |||

| Conveyors (Ø 219mm with motor) | ||||

| DIMENSIONS AND WEIGHT | ||||

| Width | mm | 2305 | ||

| Length | mm | 6055 | ||

| Height | mm | 2530 | ||

| Weight | kg | |||

The mixer is two types :planetary mixer /pan mixer

Recommended supporting horizontal silo

-Self erecting , no crane required.

-Extremely fast start-up/dismantling

-Extreme transportability for both road trailers or box containers

-Minimum environmental impact(low level silo )

-No permission required for installation

-No civil works required

|