| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Die Casting Parts |

|---|---|

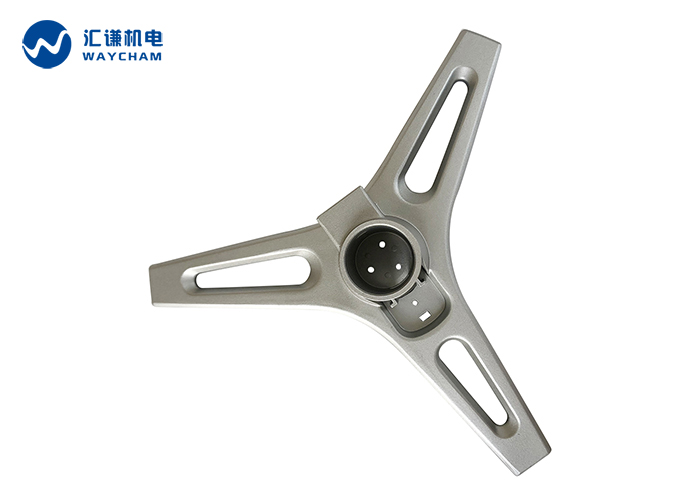

| Brand Name: | Waycham |

| Model Number: | WA-156 |

| Certification: | ISO9001:2008,SGS,ROHS,TS16949 |

| Place of Origin: | Jiangsu, China |

| MOQ: | 10pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 00000 Piece/Pieces per Week CNC Audio Part Aluminum Profile Shell |

| Delivery Time: | 5-8 work days |

| Packaging Details: | PE Foam+Plastic Bag+Carton Box+Pallet |

| Material: | ADC10,ADC12,A356,A360,A380,A383,A386,A390 |

| CNC Machining or Not: | Precision CNC machining |

| Type: | Motorcycle engine parts |

| Working Capabilities: | Die Casting |

| Process: | Investment casting |

| Surface treatmENT: | Zinc plating, brushing, pickling, sand blasting |

| Standard: | DIN,ASTM,GOST,ISO,BS,NADCA |

| Application: | Industry components |

| Tolerance: | ISO 2768-M |

| Special process: | Vacuum Die-casting, Constant Temperature Mould |

| Usage: | Industrial Shock Absorber |

ADC12 Aluminum Die Casting with CNC Machining use for Bracket

1.ODM&OEM service are all welcomed

2.Practicable Software: Solidworks,Pro/Engineer,Auto CAD,PDF,JPG

3.Mold Making Time: 10-20 days

4.Mold Life Time: 500000-1000000pieces

| Material | Aluminium alloy ACD10, ACD12, A380,Zinc Alloy, etc |

| Machine s | CNC Precision Mould Engraving Machine, CNC Forming Machine, |

| CNC Turning, EDM, Linear Cutting Machine, Die Spotting Machine(200T), | |

| Die Casting Machine(120T~1200T), Lathe, Grinding Machine, etc. | |

| Surface Treatment | Polishing, Sandblasting, Painting, Powder coating ,Galvanizing, Chrome plating |

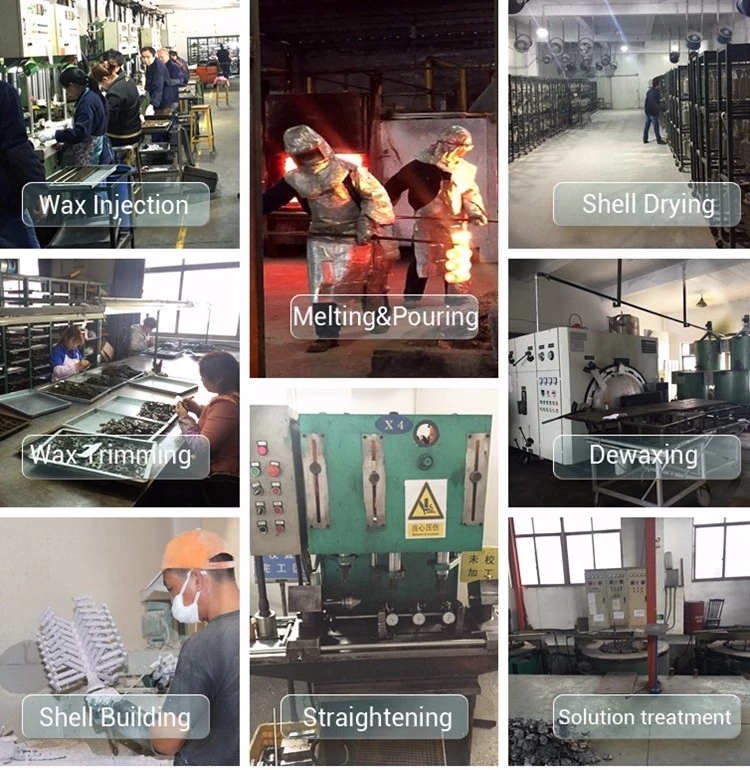

| Manufature | Confirmation Drawings - Open Tooling - Sample Approval - Incoming Qulity |

| Processes | Check - Die Casting - Fix the burrs - Drilling and Threasing - CNC Machining |

| Polishing - Internal Process Quality Check - Surface Treatment - Packing | |

| Outgoing Quality Check - Shipping | |

| Standard | ISO, DIN, ANSI, JIS, BS,NADCA and Customer Requirement |

| Drawing format | We accept DXF,DWG,IGS,STEP,and so on |

| Terms of trade | EXW, FOB, CIF |

| Lead Time | 20-25 days after order confirmed or as your request |

| Packing | Single polybag, bubble bags, wooden case, carton box, or as your requests |

| Logo | Can be made as your own logo, your own brand |

| After-sales Service | We will follow up every customer and solve all problems satisfied after sale |

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown

cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your

authorization letters.

Q2. What is your terms of payment?

A: T/T L/C,PayPal. We'll show you the photos of the products and

packages

before you pay the balance.

Q3. What is your terms of delivery?

A: FOB,

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your

advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We

can build the molds and fixtures.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our

customers benefit ;

2. We respect every customer as our friend and we sincerely do

business and make friends with them,

no matter where they come from.

Company Information:

We are committed to help clients realize the concepts and designs with support of our engineering and manufacturing advantages that includes projects made of processes like:

Our Quality promise is quite simple,we get the order and we take the responsibility:

Tooling development: | customer pay 50% of the tooling cost to us,then we develop the

tooling and provide the sample to customer,If sample delivery fail

more than 3 times,we return the money to customer. | ||

Batch production: | we take responsibility of the order quality, If such situation

happens, report to us and we find quick solution for customer | ||

With support of our comprehensive engineering and manufacturing capabilities, we improve the design to save time and cost before production. During production, our clients just need to find Bensun for all different components production.

At the moment of setup, Bensun has been placing the Quality and Service as the priority, as our team understand the Quality and Service is the key to build and maintain the mutual-beneficial relationship with our clients.

Bensun is looking forward to working with you for mutual success, your inquiry and visit is warmly welcomed.

|