| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

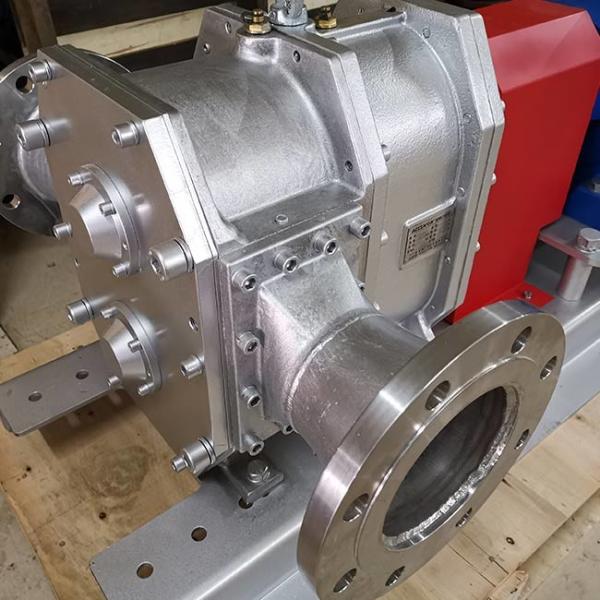

| Categories | Industrial Lobe Pump |

|---|---|

| Brand Name: | accuvon |

| Model Number: | AP 100 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Connection: | Flange DN100 |

| Rotor material: | 3-lobe, screw, FKM Rubber |

| Flow Range: | 40 m³/h |

| Speed: | 370 rpm |

| Pump casing material: | 316L Stainless steel |

| Seal Type: | SISIC / SISIC / FKM |

| Viscosity: | 50 – 1,800 cP |

| Working pressure:: | 6- 7 bar |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Petrochemical Products / Rotary Lobe Pumps / Over Pressure Protect

In the loading station of a refinery two Accuvon Rotary Lobe Pumps are being operated for various petrochemical products. The smaller units fills up drums, the larger AP 100 loads truck units. The relief valve is installed as mechanical over pressure protection and control device for additional operational safety.

Application data:

| Pump | AP 100 |

| Medium | Petrochemical Products |

| Flow Rate | 40 m³/h |

| Pump Speed | 370 rpm |

| Solids | / |

| Environment | EX DIIBT4 |

| pH value | Neutral |

| Temperature | approx. 30° C |

| Pressure | 6 - 7 bar |

| Viscosity | 50 – 1,800 cP |

Technical data::

| Casing | 316L Stainless steel |

| Casing protection plate | 316L Stainless steel |

| Static O-rings | FKM |

| Shaft seal | SISIC |

| O-Rings (dynamic) | FKM |

| Rotors | tri-lobe screw profile, FKM |

| Drive | 15 Kw |

Advantages of this Accuvon AP 100

· EX (explosion proof)

· Self priming

· low shear

· resistant to solvents

· good wear resistance

· slightly viscous media

· Reduced maintenance times and downtimes

Production processes in the oil industry depend heavily on robust and durable pumping systems. The wide range of pump sizes, the option loaded modular design and the peripheral equipment enable Accuvon to supply a suitable Rotary Lobe Pump for your oil application. Accuvon Rotary Lobe Pumps are manufactured to the Explosion Proof Standard.

The Accuvon MIP-Design is a unique advantage to minimize downtime and maintenance: MIP (Maintenance In Place) allows the quick and convenient replacement of all fluid wetted parts without removal of pipes, drives or other components of the pump unit by your own staff. Quick - Uncomplicated - Inexpensive.

Petrochemical fluids often include abrasive and aggressive characteristics. Wide viscosity ranges demand customized solutions for pumping systems: Accuvon offers rotor materials with different coatings (Elastomer, PTFE or Urethane) or solid stainless steel rotors. Casing protection plates are supplied with different steel, plastic or ceramic quali[1]ties. For operational safety the Accuvon relief valve can be added as a mechanical over pressure protection device.

Variety of Rotor Designs Rotor geometry and materials are customized for each individual application Rubber elastomers, Urethane or stainless steel lobe designs are available.

Similar application of sewage treatment:

Accuvon provides many applications on-board ships and in other areas of the marine industries - from handling of both fresh and seawaters to fuels of all kinds, oil or oil sludge, bilge or other water-oil mixtures, fish or fish waste, sewage or other fluids with or without solids, of low or high viscosities.

Sewage | Ballast Water | Bilge / Loading | Oil Sludge | Fuel / Crude Oil | Oil-Water Separation | Fish / Kitchen Waste | Mud | Emulsions | Oilfield Chemicals | Marine Diesel Oil | as Skimmer Pump

Features of Accuvon Rotary Lobe Pumps:

1.Self-priming, Valve-less, Positive Displacement Pump

2. Easy Maintenance through Front Cover

3. Controllable Flow, Ratio up to 1 : 5

4. Capacity of up to 3200 m³/h

5.Pressures of up to 25 bar

6. Dry-running Capability

7.Reversibility, same pump output for both directions

8. Gentle, Low-Pulsation Pumping

9.For Viscous, Solid, Abrasive or Shea-sensitive Mediums

10. Low Parts Replacement Costs

Components of a Accuvon Rotary Lobe Pump

1 Timing gear

2 Quench and control chamber

3 Casing in block design

4 Unwetted shaft

5 Axial and radial casing protection

6 Shaft seal

7 Rotors

8 Quick-release cover

|