| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Twin Shaft Grinder |

|---|---|

| Brand Name: | accuvon |

| Model Number: | HAP 120 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Type: | Dual-shaft grinder HAP 120 |

| Connection: | Flange DN100 |

| Grinder: | Hart metal |

| Flow Range: | 40 m³/h |

| Speed: | 120rpm |

| Pump casing material: | GG25 Grey cast iron |

| Seal Type: | Mechanical Seal |

| Solids Content: | 3 -5 TS |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Primary Sludge Excellent cutting result , twin-shaft grinder for WWTP

A major sewage treatment plant experienced several instances of pump faults upon their change in processes, which causes an increase in dry matter content of the primary sludge that resulted in agglomerated solids clogging up the pumps.

Following the successful implementation of Accuvon HAP120 twin Shaft Grinder through various tests; for the reduction of the primary sludge;the Accuvon HAP120 twin Shaft Grinder was installed on the suction side of two primary sludge pumps that handle the sludge alternately.

The excellent grinding result, interchangeable blades with different profiles that allows different degrees of communition, space-saving design etc… had convinced the sewage plant operators to replace all existing shredders by our Accuvon twin Shaft Grinders.

operating principle

The dual-shaft grinder was designed using the principle of the Accuvon Rotary Lobe Pump. Instead of the rotating lobes, this device has interconnecting cutting blades set on the hexagonal carrier shaft and attached with a central bolt.

The different circumferential speeds and blade configurations ensure excellent cutting results.

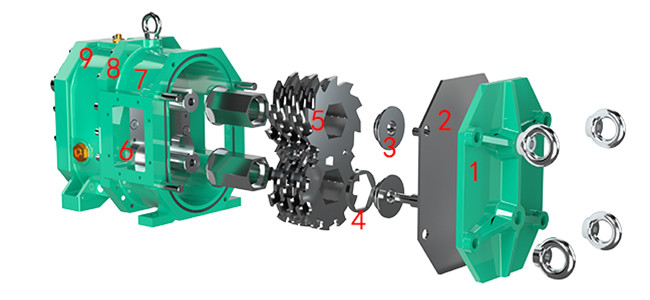

Components

1 Quick-release cover

2 Axial casing protection

3 Central clamping unit

4 Spacer rings

5 Cutting blades

6 Shaft seal

7 Block casing

8 Quench and control chamber

9 Carrier gear unit and gear reducer

blade configurations

The degree to which the Accuvon Crusher cuts is determined by the choice of blade configuration, the teeth profiles, the blade widths and the flow speed.

Currently, a choice of nine different blade configurations can be selected depending on the assignment. The different circumferential speeds of the shafts create a tearing/cutting result. The use of hardened steel ensures the blades are kept sharp for longer. Defective cutting blades can be individually replaced.

Control technology

The Crusher generally runs in reverse for 5 seconds upon starting – afterwards changing to the original direction of rotation

Reversing in the event of overload (blockages or clogging): Reversing upon reaching 70% of the motor power rating (value can be freely configured via the control unit)

Alert: when reversing five times within ten minutes due to overload Counter which runs in the background to record the number of load-dependent reversals

The Accuvon control technology guarantees trouble-free operation of the Crusher.

design options

combined with a rotary lobe pump; can also be combined with other pumps

advantages

Macerating Technology data:

| Medium | Primary Sludge |

| Flow Rate | Up to 40 m³/h |

| Speed | 120rpm |

| Temperature | 20 °C |

| direction | Reversible operation |

| Solids Content | 3 – 5 % TS |

Application data of Dual-shaft grinder:

| Type | Dual-shaft grinder |

| Grinder | Crusher |

| Casing | Grey cast iron |

| Casing protection plates | Hart metal |

| O-Rings | NBR |

| Shaft sealing | SiSiC / SiSiC |

| Knife geometries | long shaft F16Z, short shaft G10Z |

| Drive | 3 kW |

Model data sheet:

| Model | Flow(max) | velocity of flow | Standard DN mm | Optional DN mm | Standard power | Optional power |

| HAP80 | 25m³/h | 3m/s | DN80 | DN100 | 3Kw | 4Kw |

| HAP100 | 40m³/h | 3m/s | DN100 | DN125 | 3Kw | 4Kw |

| HAP120 | 60m³/h | 3m/s | DN100 | DN125 | 3Kw | 4Kw/5.5Kw |

| HAP140 | 80m³/h | 3m/s | DN125 | DN150 | 3Kw | 5.5Kw |

| HAF125 | 100m³/h | 3.1m/s | DN125 | DN150 | 7.5Kw | 11Kw |

| HAF150 | 150m³/h | 3.1m/s | DN150 | DN200 | 11Kw | |

| HAF200 | 200m³/h | 3.1m/s | DN200 | DN250 | 11Kw | |

| HAX250 | 300m³/h | 2.4m/s | DN250 | DN300 | 18.5Kw | |

| HAX300 | 500m³/h | 2.4m/s | DN300 | DN350 | 18.5Kw |

|