| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rubber Lobe Pump |

|---|---|

| Brand Name: | ACCUVON |

| Model Number: | AP 140 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Rotor Type: | Wear-resistant Rubber Rotor |

| Medium: | Liquid containing particles |

| Material of pump: | Gray Cast Iron |

| Flow: | 2.2-133 m³/h |

| Speed: | 600 rpm |

| Rate of flow: | 3.714 l/rev |

| Axial and radial casing protection: | XAR400 Hardmetal |

| Drive: | Hydraulic motor |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

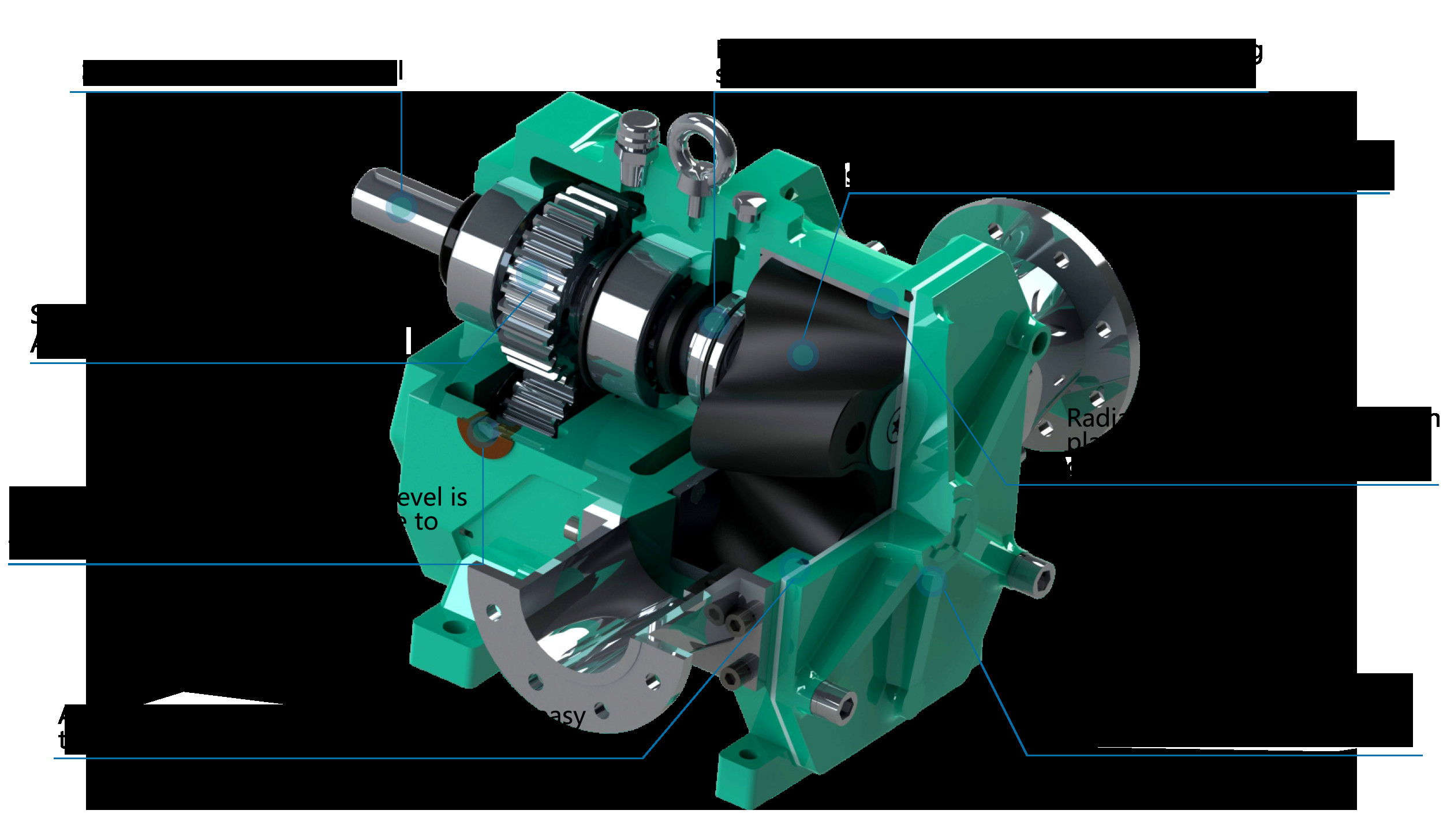

Equip Hardmetal Protection Plate Rubber Lobe Pump For Chemical Liquid

ACCUVON Rotary Lobe Pump

Rotary Lobe Pumps are self-priming, valve less, positive displacement pumps. With speed-proportional flow, they continuously deliver trouble-free pumping of liquids of various consistencies and multiphase mixtures. They are compact and operate with low shear and low pulsation.

Specifications:

| ACCUVON | rate of flow l/rev | flow (m³/h) | pressure (Mpa) | speed rpm | Flange diameter DN mm | power Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Note: Above flange is regular for each model, besides we also offer various flange connection according to your requirements

Technical Detail

| Model | AP 140 |

| Rotor | Rubber rotor |

| Seal | Double mechanical seal |

| Axial and radial casing protection | High-strength steel , resistant to wear |

| Drive | Electric Motor,diesel engine, hydro turbine, hydraulic motor |

| Material of pump | Cast Iron, Stainless steel |

| Pressure | 0-0.6 mpa |

| Flow | 2.2-133 m³/h |

| Power | 7.5-22 / KW |

| Speed | 10-600 rpm |

| Work efficiency | Up to 85% |

| Rate of flow | 3.714 l/rev |

| Self - priming | Up to 9.5m vertical / 30m horizontal |

| Medium | High-corrosive / high-viscous |

Advantage

--Capacity up to 1800 m3/h

--Head up to 120 m

--Solids handling up to 95 mm

--Viscosity up to 100000 cp

--Technical features: Wide selection of models (including mobile and ATEX), sizes and materials

--available three type of mechanical seals types

--Casing in block design

--Pump shaft does not become in contact with the pumped liquid

--Wide selection of rotors, which can be adapted to specific parameters (including versions with replaceable lobe tips and special version for biogas industry)

--Self-priming, no vacuum system necessary

--Pump can be used in both horizontal and vertical position

--Easy pump maintenance, no line disassembling necessary

--Replaceable wear plates in casing upper and bottom part (option), as well as in front and rear part (standard)

--Quench chamber between pump casing and gear box Adjustable flow 1:6

--Can pump chemically aggressive and viscous liquids

--Can be reversed

--Capable of running without causing damage

--Can be driven by electric, diesel, hydraulic, pneumatic engine and PTO Compact size

Structure features

The pump cavity design is so simple. All models of pumps retain simple design styles. The fast -opening pump cover is opened to provide guarantee for user maintenance personnel without disassembling the pipeline. The driver can guarantee online repair. Greatly reduced the stop time. Before and after, the upper and lower wear -resistant internal lining design, comprehensively ensure the non -wear of the pump shell and ensure long -term durability. Such a simple maintenance characteristics reduce the operating cost of the entire life cycle of the equipment.

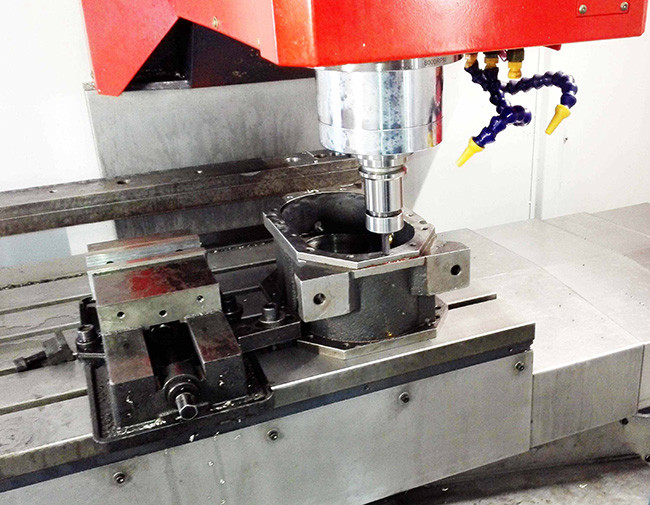

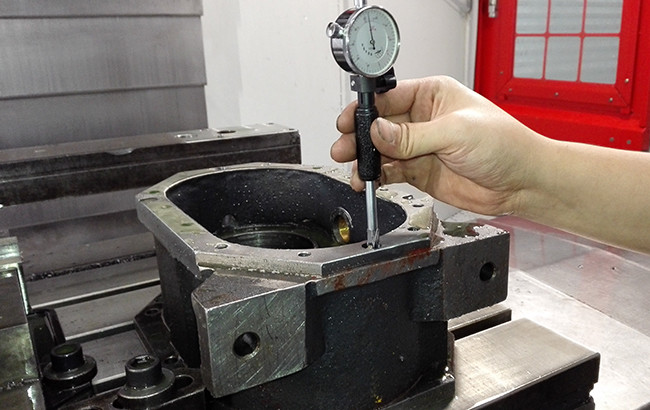

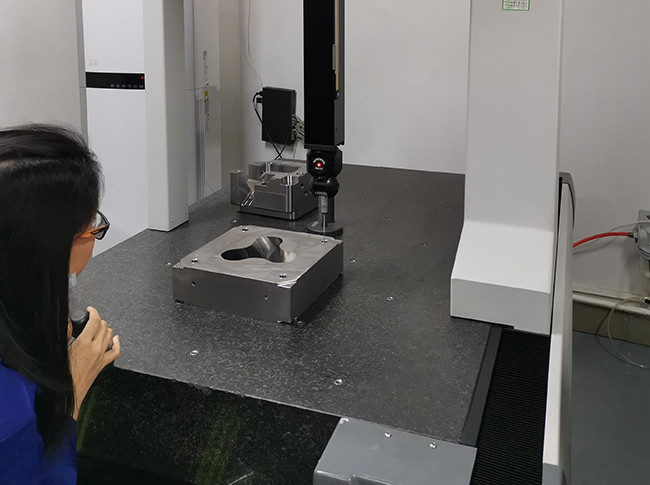

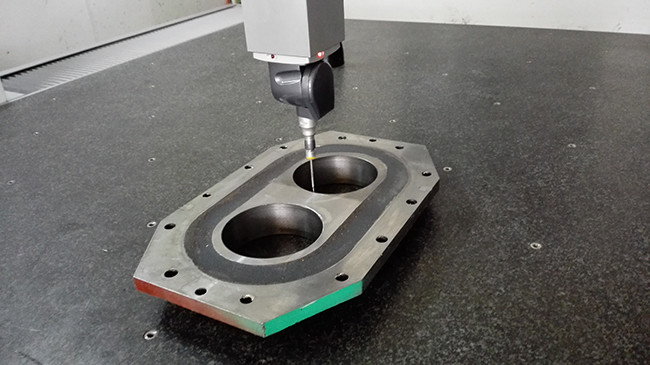

Quality inspection photos

|