| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Rotary Lobe Pump |

|---|---|

| Brand Name: | ACCUVON |

| Model Number: | AX 350D |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Rotor Type: | EPDM Rubber |

| Flange Connection: | DN 200 / DN 250 / DN 300 / DN 350 / DN 400 |

| Main Products: | Lobe Pump |

| Flow Range: | 45 - 2926 m³/ h |

| Seal: | Double mechanical seal |

| Axial and radial casing protection: | XAR500 Hard metal |

| Drive: | Variable speed gear motor |

| Power: | 90 - 450 KW |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Resistant To Solids Positive Displacement Rotary Lobe Pump

ACCUVON Rotary Lobe Pump

Rotary Lobe Pumps are self-priming, valve less, positive displacement pumps. With speed-proportional flow, they continuously deliver trouble-free pumping of liquids of various consistencies and multiphase mixtures. They are compact and operate with low shear and low pulsation.

Specifications:

| Description | Rotary Lobe Pumps |

| EPDM Rubber | EPDM Rubber |

| Seal | Double mechanical seal PLAN53A |

| Axial and radial casing protection | XAR500 Hardmetal |

| Drive | Variable speed gear motor |

| Material of pump | Full of carbon steel |

| Pressure | 0 - 0.6 Mpa |

| Flow | 45 - 2926 m³/ h |

| Power | 90 - 450 KW |

| Custom printing | Acceptable |

Parameter of AX 350D

| Drive | Weight | Dimensions | |

| KW | KG | L / mm | H / mm |

| 45 | 2000 | 2688 | 1005 |

Design 1 | Short, straight pipe connectors with connection flange and gasket, in mm / inches approx.

| AX 350D | DN 200 / mm | DN 250 / mm | DN 300 / mm | DN 350 / mm | DN 400 / mm |

Advantages Lobe Pumps

Components

1. Quick-release cover

The robust construction of the Rotary Lobe Pump, which always features a single-sided bearing, permits use of a quickrelease cover, through which all parts subject to wear can be inspected and replaced quickly and without major effort. The cover can be removed after releasing only four ring nuts. This makes maintenance quick and easy.

2. Axial and radial casing protection

Installed axially as standard between pump casing and rotor are casing protection plates or sheets.

3. Rotors

Various rotor contours and designs based on different materials : e.g. elastomers, plastics or metal can be used, depending on the pumped medium.

4. Shaft seals

In contrast to many other positive displacement pumps, ACCUVONRotary Lobe Pumps feature the single-acting mechanical seal with quench as standard.This maintenance-free shaft seal is available in diverse sliding surface materials specially adapted to the pumped medium. Special versions in the form of pressurized or double-acting seal faces are also optionally available.

5. Non-wetted shaft

The carrier shafts of the Rotary Lobe Pumps do not come into contact with the pumped medium due to the self-sealing design.

6. Casing in block design

the pump casing is made of a single cast part and manufactured to narrow tolerances. It is available in high-quality gray cast iron, spheroidal cast iron or stainless steel.

7. Quench and control chamber

The liquid-filled and separately sealed control chamber separates the carrier gear unit from the pump chamber.

it protects the gear unit from penetration by the pumped medium while protecting the pump chamber from contact with gear oil. It also serves as the quench chamber for the mechanical seals.

8. Carrier gear unit and timing gear

The timing gear and carrier gear unit represent a separately sealed component. The high quality and extremely sturdy gear wheels ensure even, smooth operation, as well as long service life

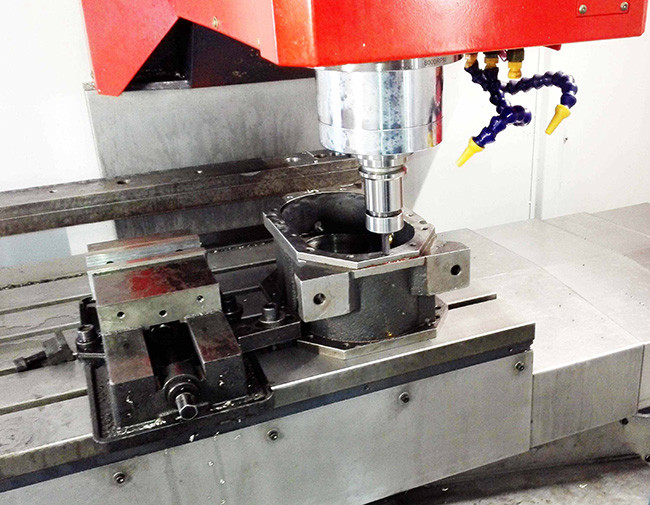

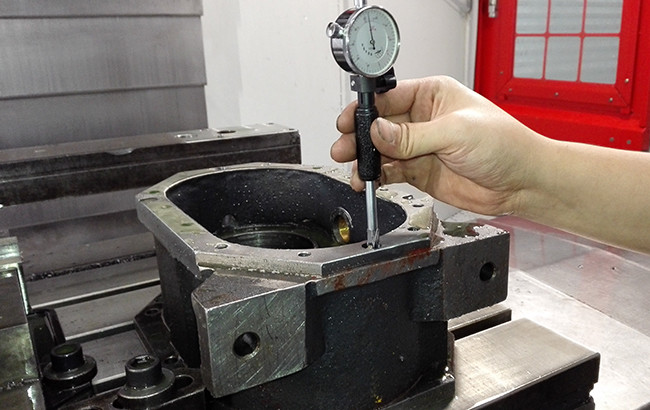

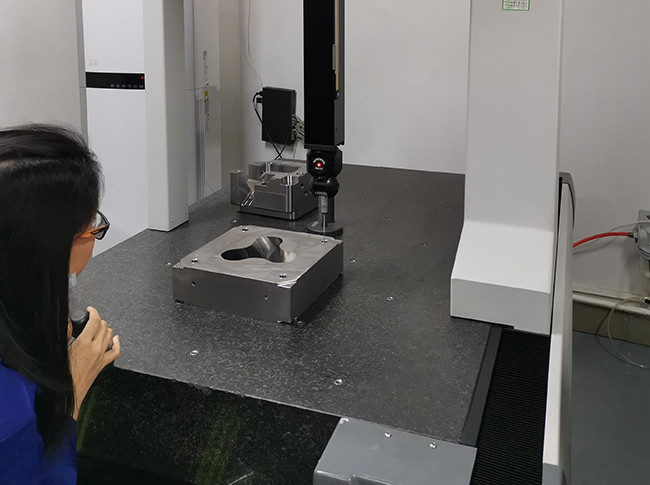

Quality inspection photos

FAQ:

Q: How can I make order ?

A: Contact us and tell us your requirements, and then we will send quotation as your request.After finished payment, we will arrange shipping for you.

Q: Which payments are acceptable?

A: T/T, L/C, Western Union, Paypal

Q: Which shipping terms are available?

A: By sea, air, Express

Q: How about the delivery time?

A: It is normally 5-10 working days after payment, Depends on your quantity.

Q: What guarantee do you have?

A: The product warranty period is 1 years, except for wearing parts (if the product fails to work normally due to poor manufacturing, the company will replace and repair products and parts for users free of charge. Product damage caused by human causes is not covered by the warranty.

Q: Can I purchase parts separately?

A: Yes, all pump spare parts can be purchased separately.

|