| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Coil |

|---|---|

| Brand Name: | TISCO |

| Model Number: | 301L, 301, 310S, 410, 316L, 316, 314,420, 430, 304, 304L, 305 |

| Certification: | ISO9001 |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1MT |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union/Paypal |

| Supply Ability: | 2000MT/Month |

| Delivery Time: | 3-15work days |

| Packaging Details: | Exporting package/wooden box package/Or per customers’ requirement |

| Product name: | No.4 Stainless Steel Coil |

| Material: | 200 Series/300 Series/400series/904L/2205 |

| Thickness: | 1.5-15mm 0.3-3.0mm |

| Width: | 1000 1220 1500 1800 2000mm |

| Price term: | CIF CFR FOB EX-WORK |

| Coil weight: | 1MT - 10MT,20MT |

| Company Info. |

| Jiangsu Pucheng Metal Products Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Mill Edge No.4 Stainless Steel Coil width 1219mm 1200mm 1500mm 410 420 430 For Knife

Description:

A 'No 4' surface is produced by cutting the surface with abrasive belts to remove a very small amount of metal without affecting its thickness. For architects and designers, No 4 finish gives low gloss and best apparent flatness of panels.Mill edge is a non-trimmed edge appearance after hot / cold rolling and annealing/ pickling process. It usually leaved an irregular pinhole line on the edge side around 10mm - 15mm.The everyday rigors placed on cutlery demand a material that exhibits excellent strength, lasting durability, and resistance to mildly corrosive environments. For this reason, 410 stainless steel has become a staple in the manufacturing of knives and flatware.420 stainless steel alloy is commonly used in knife blades. Its high-strength and corrosion-resistant properties make it an ideal material for knives that are frequently exposed to the elements.

Product | Stainless Steel Coils |

Material Type | Magnetic / Non-Magnetic |

Standard | GB JIS AISI SUS ASTM DIN TUV BV etc |

Grade | 410,420/430,409,201,304,316,316L,etc |

Technology | Cold Rolled |

Thickness | 0.15mm to 2.0mm or customized |

Width | 10mm to 1290mm or customized |

Surface | BA, 2B,A 2B, NO.4, HL, Mirror |

Edge | Mill Edge, Slit Edge |

Other Choices | Leveling: improve flatness, esp. for items with high flatness

request. |

Skin-Pass: improve flatness, higher brightness | |

Strip Slitting: any width from 10mm to 1290mm | |

Sheets Cutting: Square Sheets, Retangle Sheets, Circles, Other

Shapes |

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤ 0.03 | 3.5-5.5 | 16.0-18.0 | - |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 6.0-8.0 | 16.0-18.0 | - |

| 304 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 8.0-13.0 | 18.0-20.0 | - |

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.0-13.0 | 18.0-20.0 | - |

| 309S | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤ 0.03 | 12.0-15.0 | 22.0-24.0 | - |

| 310S | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 19.0-22.0 | 24.0-26.0 | - |

| 314 | ≤0.25 | ≤1.5-3.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 19.0-22.0 | 23.0-26.0 | |

| 316 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 10.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.0 | ≤2.0 | ≤0.035 | ≤ 0.03 | 9.013 | 17.0-19.0 | - |

| 347 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤ 0.03 | 9.0-13.0 | 17.0-19.0 | |

| 410 | ≤0.15 | ≤1.0 | ≤1.0 | ≤0.035 | ≤ 0.03 | - | 11.5-13.5 | - |

| 420 | ≤0.16-0.25 | ≤1.0 | ≤1.0 | ≤0.040 | ≤ 0.03 | - | 12.0-14.0 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.0 | ≤0.040 | ≤ 0.03 | ≤0.60 | 16.0-18.0 | - |

| 904L | ≤0.02 | ≤1.0 | ≤2.0 | ≤0.045 | ≤ 0.03 | 23.0-28.0 | 19.0-23.0 | - |

SURFACE | PROCESSING METHODS | APPLICATION |

NO.1 | The surface finished by heat treatment and pickling or processes

corresponding there to after hot rolling. | Chemical tank, pipe. |

2B | Those finished, after cold rolling, by heat treatment, pickling or

other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen

utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

8K | The product is continuously processed with 1000# abrasive thus it

is with high gloss and reflection properties. | Contruction,mirrors,plate sets,decorations,ect. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives

specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

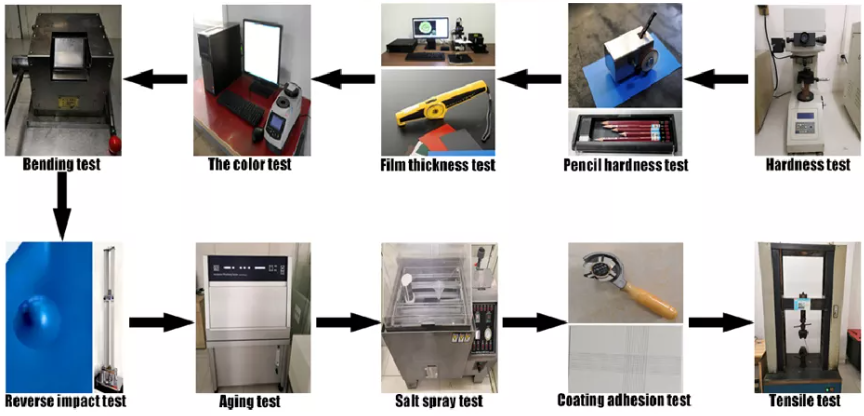

Quality Test:

Application:

Package:

About Us:

Jiangsu Pucheng Metal Products (Group) Co., Ltd provides customers

with different specifications and materials for stainless with 10

years' experience.Special Purpose with high quality, fast delivery,

competitive price and excellent exprience of after-sale service.We

have keep highly appreciated cooperation with purchasers from many

countries .If you are interested in our products, please feel free

to contact me any time! Welcome to hear from your inquiry!

FAQ:

Q:Why should you buy from us not from other suppliers?

A:Our company has advanced production equipment, can meet customer

customized service requirements, product quality and deliveryspeed

are the world's leading level.Professional packaging team and

quality inspection team, professional steel supplier service.

Q:Can you send samples?

A:Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

Q:What is your terms of payment ?

A:T/T, 100% L/C at sight, Cash, Western Union are all accepted if

you have other payment,please contact me.

|