| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Waterproof Aluminum Decking |

|---|---|

| Brand Name: | KaiLun |

| Model Number: | KL-K40479 |

| Certification: | ISO/TS16949:2009 |

| Place of Origin: | Zhenjiang,Jiangsu China |

| MOQ: | 1 Tons |

| Price: | Negotiation |

| Payment Terms: | T/T, L/C... |

| Supply Ability: | 3000Tons / Month |

| Delivery Time: | Within 12 days after received your deposit |

| Packaging Details: | EP paper + Kraft Paper + Plywood pallet, as per export packing standard, custom packaging is available |

| Product Name: | Aluminum Skirt Board |

| Usage:: | for Auto Accessory |

| Shape:: | Flat Bar |

| Alloy or Not: | Alloy |

| Deep Process:: | Cutting, Milling, Drilling, Punching,CNC,etc |

| Company Info. |

| Jiangsu Karen Aluminum Co.,Ltd |

| View Contact Details |

| Product List |

6000 Series Extrusion Aluminium Skirting Boards for Auto Accessories on Pedal Plate

Detailed Product Description:

Product Name: | Aluminum Profile for Auto Accessory | Alloy: | 6005, 6063, 6061, etc. |

|

|

| Mill Finished, Anodizing, Electrophoresis, |

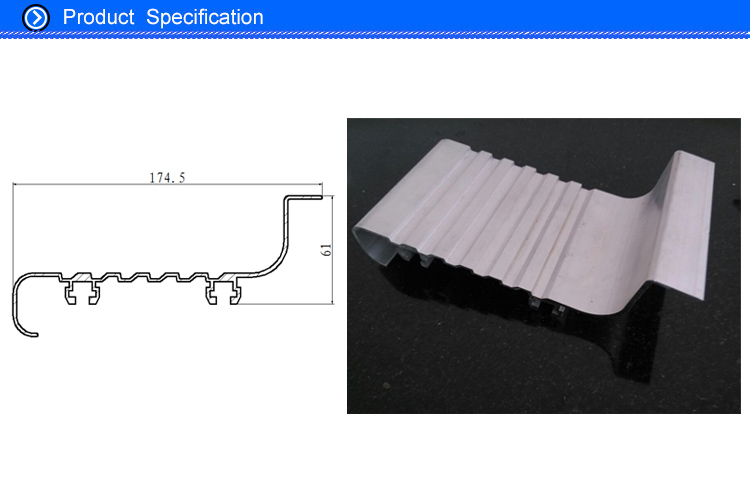

| Size: | 174.5*61mm | Weight: | 1.98 kg/m |

Deep Process : | Milling, Drilling ,Bending, Cutting | Temper: | T5,T6 |

Primary Technical Data:

1) Chemical composition

Alloy | Si | Mg | Fe | Cu | Mn | Zn | Cr | Ti |

6063 | 0.2~0.6 | 0.45~0.90 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

6060 | 0.3~0.6 | 0.35~0.60 | 0.1~0.3 | ~ | <0.10 | <0.15 | <0.05 | ~ |

6463 | 0.2~0.6 | 0.45~0.90 | <0.15 | <0.20 | <0.05 | <0.05 | ~ | ~ |

6005 | 0.6~0.9 | 0.40~0.60 | <0.35 | <0.10 | <0.10 | <0.10 | <0.10 | <0.10 |

6061 | 0.4~0.8 | 0.80~1.2 | <0.70 | 0.15~0.4 | <0.15 | <0.25 | 0.04~0.35 | <0.15 |

6082 | 0.7~1.3 | 0.60~1.2 | <0.50 | <0.1 | 0.4~1.0 | <0.20 | <0.25 | <0.10 |

6351 | 0.7~1.3 | 0.40~0.8 | <0.50 | <0.1 | 0.4~0.8 | <0.20 | ~ | <0.10 |

2) Mechanical property

Alloy | Temper | Tensile strength | Yield strength | Elongation |

6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% | |

6061 | T5 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

Product Drawing:

Advantages of our extrusion process :

The extrusion process provides virtually unlimited opportunities

for aluminium product shapes. Costs are cut by designing fewer

components, which reduce fabrication and simplify assembly.

These features and benefits are unmatched by other materials and

processes:

(1) Complex integral shapes

(2) Cost effective

(3) Low tooling costs

(4) Design flexibility

(5) Versatility in joining

(6) Machinable

(7) Rapid prototyping

(8) Short lead times

(9) Wide range of finishes

|