YAG Small CNC Fibre Laser Cutting Machine With Low Electric Power

Consumption

Description

The machine adopts the advanced German IPG fiber laser/ Chinese

Raycus fiber laser, available to cutting most of the metal sheet

materials. Integrated design of machines tool accessories, fast

disassemble and installation; funnel collection of both left side

and right side, space-saving, energy saving, and low cost. Movable

Gantry machine tool structure, to ensure long-time stability and

security, Import servo systems and CNC systems, with good

compatibility, strong stability, convenient maintenance and

excellent processing capacity.

Product Features

1. Adopt high efficiency laser tube and more stable beam.

2. With the function of restoring from power off,continuation on

break point.

3. Advanced control system with usb, professional motion control

chip,consecutive high speed curve cutting and the shortest path

selection function improve the efficiency.

4. Red light positioning device indicates the location of laser

head,eliminate the trouble about manual positioning.

5. Can engrave and cut and achieve perfect unification of two

functions.The machine has stable performance, simple operation and

wide processing materials, is equipped with electric lifting

platform, has high speed and precision, and is the best updating

choice of all walks of life.

Application

Applied in sheet metal processing, aviation, spaceflight,

electronics, electrical appliances, subway parts, automobile,

machinery, precision components, ships, metallurgical equipment,

elevator, household appliances, gifts and crafts, tool processing,

adornment, advertising, metal foreign processing various

manufacturing processing industries.

Specifications

| Working Area | 1500*3000mm |

| Laser Power | 300W IPG fiber power source |

| Laser Wave Length | 1064nm |

| Working Table | Saw tooth |

| Maximum Idle Running Speed | 1400mm/s |

| Position Accuracy | ±0.03mm/m |

| Moving Speed | 60m/min |

| Minimum Line Width | ± 0.02mm |

| Control System | Cypcut |

| Position Type | red dot |

| Power Consumption | ≤12KW |

| Working Voltage | 380V/50Hz, three phase |

| Auxiliary Gas | oxygen,nitrogen,air |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | Lasermech made in USA |

| Focus lens | Lasermech made in USA |

| Driver system | 1500W servo motor made in Japan |

| Liner guider system | PMI H series linear guide made in Taiwan , |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Herion made in Germany |

| Chain system | Igus made in Germany |

| Warranty time | Whole machine for 3 years (fiber module 2 years ) |

| Gross weight | 1500kg |

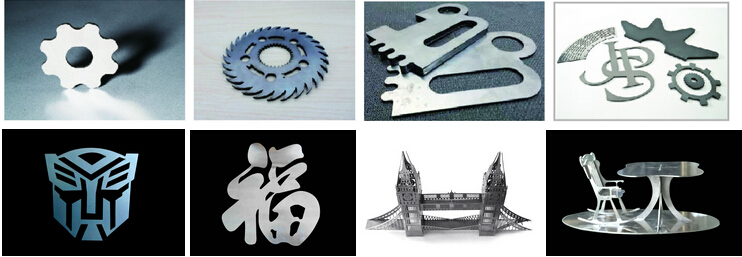

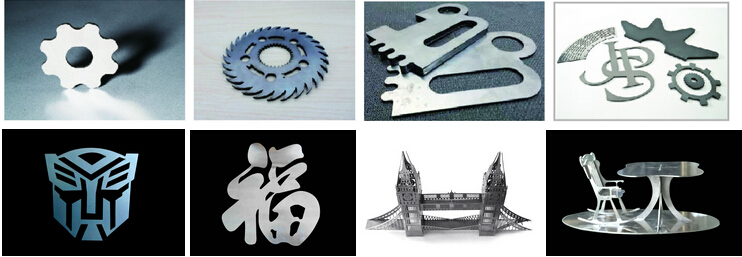

Cutting Samples

Packaging and delivery

1. Standard plywood case, its compressive strength and bearing

quality is better.

2. the board area is bit, the soil structure is good, it is better

in leakproofness and waterproof.

3. when importing, the plywood case is with fumigation-free, the

procedure is simple.

4. Delivery Detail: within 20-25 days after received your payment.