| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ni Hard Liners |

|---|---|

| Brand Name: | Chen's Liner |

| Model Number: | DF1314 |

| Certification: | ISO 9001:2008 |

| Place of Origin: | Jiangsu, China (Mainland) |

| MOQ: | 2 Ton/Tons |

| Price: | According to the quantity to be ordered |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 4500 Ton/Tons / Year |

| Delivery Time: | It depends on quantity to be ordered |

| Packaging Details: | Steel Pallets or Flexible Container Bags or Customized |

| Material: | AS 2027/NiCr1-550 |

| Technique: | Sand Process |

| Dimension: | As per drawings |

| Unite Weight: | 35-45kg |

| Hardness: | ≥HRC54 |

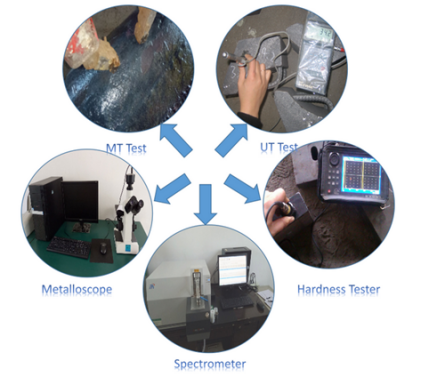

| Inspection: | UT&MT |

| Heat Treatment: | Quenching&Tempering |

| Package: | Steel Pallet |

Ni-hard Castings With Material AS 2027/NiCr1-550

| Composition (%) | C | Si | Mn | Cr | Mo | Ni | P | S |

| AS 2027/NiCr1-550 | 3.2~3.6 | 0.3~0.8 | 0.2~0.8 | 1.5~3.0 | ≤0.5 | 3.0~5.0 | ≤0.06 | ≤0.06 |

| AS2027/NiCr-630 | 3.2~3.6 | 1.5~2.2 | 0.2~0.8 | 8.0~10.0 | ≤0.5 | 4.0~5.5 | ≤0.06 | ≤0.06 |

Hardness:

Ni-hard castings with material AS 2027/NiCr1-550: ≥HRC54;

Ni-hard castings with material AS2027/NiCr-630: ≥HRC59;

Heat treatment:

1. Ni-hard castings with material AS 2027/NiCr1-550: Heat treat at about 500℃ for 4 hours to 16 hours with air or furnace cooling and temper at 250~300℃ for 4 hours to 16 hours with air or furnace cooling.

2. Ni-hard castings with material AS2027/NiCr-630: Heat treat at about 800℃ for 6 hour to 12 hour with air or furnace cooling and temper at 250~300℃ for 8 hours to 12 hours with air or furnace cooling.

Package:

Packed in steel pallets.

Test facilities include Spectrometer for chemical analysis, HRC table hardness tester, HBN table hardness tester, two portable hardness testers, impactor and universal material testing machine for inspection of mechanical properties, matrix microscope for metallographic examination, ultrasonic tester for ultrasonic inspection and magnetic particle tester for magnetic testing.

These facilities are used to ensure the consistent quality of products. We achieved the certificate of quality management system ISO 9001:2000. Our current capacity of finished castings is 4500 tons / year. We have a good credit of delivery of products in accordance with the contracts.

Wuxi Orient Anti-wear specialize in production of wear, heat and corrosion-resistant castings and the relevant grinding equipments. We were awarded the certificate of High New Technology Enterprise issued by Sci-tech Bureau, Jiangsu Province in 2004.

We are a Chinese specialized manufacturer of wear, heat and

corrosion-resistant castings.

Our main products are ball mill liners, grinding media and wear

parts for crushers.

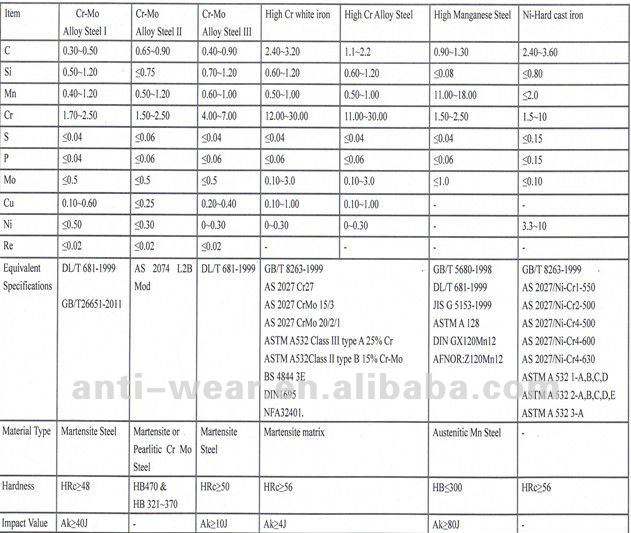

Our products involve various kinds of materials, such as low Chrome

alloy steel, middle Chrome alloy steel, high Chrome alloy steel,

high chromium white iron, low chromium cast iron, Ni-hard cast

iron, high Manganese steel and other heat and corrosion-resistant

castings.

Our foundry has necessary production and heat treatment equipments,

such as mid-frequency induction electrical furnaces, quenching and

tempering furnaces, blast shot.

A. Specialize in wear, heat and corrosion-resistant castings over 20 years

B. Customized service as per customers’ requirements

C. Comprehensive training for installation on-site and operation

D. Strong problem solving ability on site

E. Patented technologies utilized in manufacturing process

|