| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tandem Cold Mill |

|---|---|

| Brand Name: | Jinye |

| Model Number: | 750 |

| Place of Origin: | Wuxi, China |

| MOQ: | 1Set |

| Payment Terms: | T/T |

| Delivery Time: | 120 -180days |

| Packaging Details: | 8x 40HC |

| Name: | 2 Heads Tandem Cold Rolling Mill |

| Material: | Black HR Steel Coil non pickled |

| Input: | 2-3 x 650mm |

| Output: | 0.8-1.5 x 650mm |

| Rolling speed: | 150m/min |

| Work roller: | dia190 x 750 |

| Backup roller: | dia650 x 730 |

| Press down: | mechanic screw |

| total power: | 1800KW |

| Land area: | 35m x 15m |

| Company Info. |

| WUXI JINYE COMPLETE EQUIPMENT CO.,LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

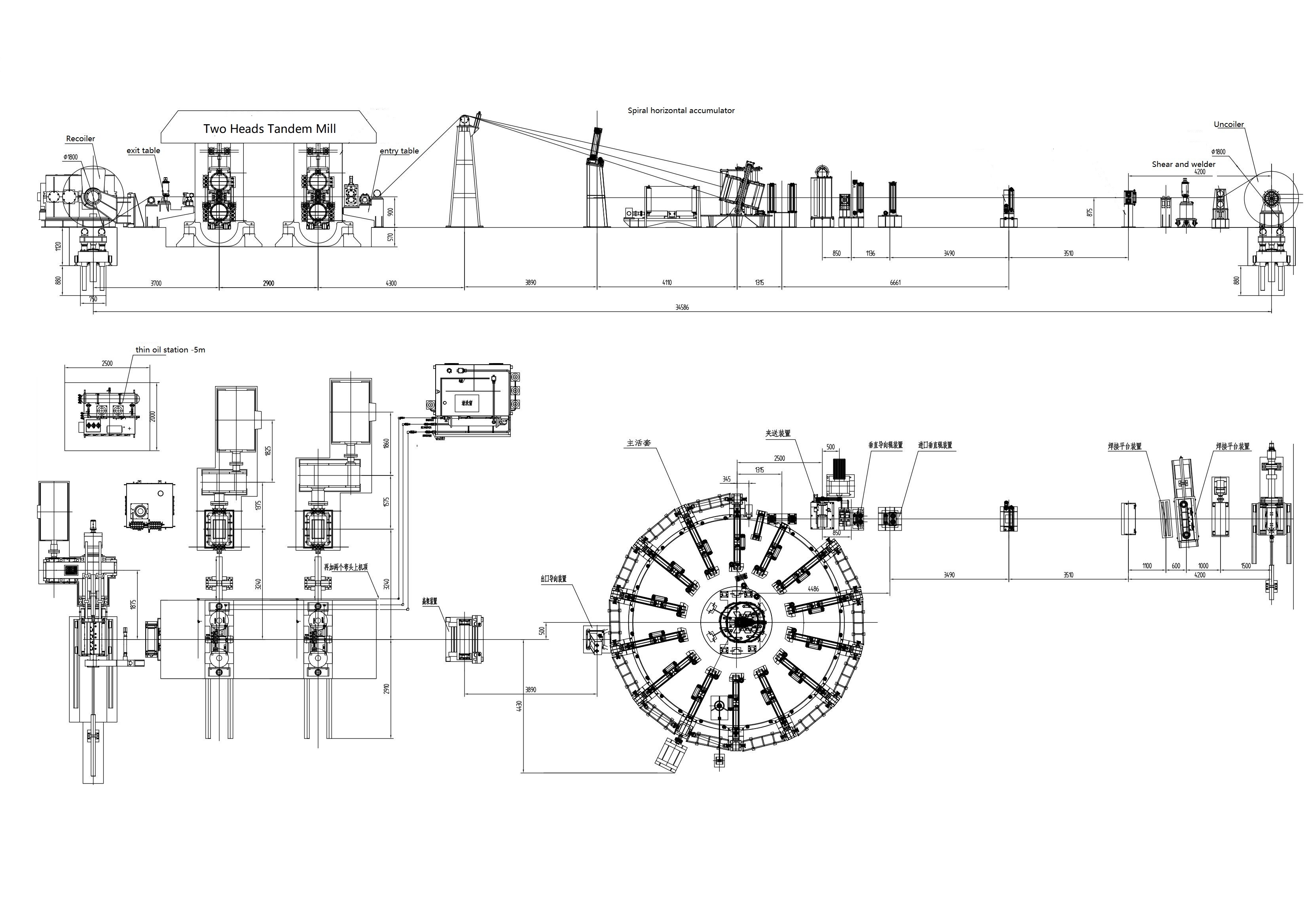

2 Heads Tandem Cold Rolling Mill For Black HR Steel Coil

Plain carbon steel coil processing plant witness tandem cold rolling mill who continuously reduce steel plate thickness at hundreds of meters per minute, the tandem rolling mill can give multiple production.

The competition of the tandem mill is continuous rolling: one way

from uncoiling to coiling and working without stop, so, automatic

shear and welding machine, strip accumulator and double recoilers

are on the rolling line.

Automatic shear & welding and spiral accumulator keep uncoiling and

strip feeding continuous, double coilers are good way to keep

continuous coiling. These characters of tandem rolling machine make

automation and production go to huge scale.

For non pickled black Hot Rolled mild steel strip cold rolling, two heads tandem mill is popular, because it reduces thickness two passes continuously to reach the required 50 -60% gauge reduction.

The rolling process includes uncoiler, shear welder, accumulator, two heads mill and recoiler. hydraulic system, electric control system, lubricating system are the indispensible conditions for the tandem cold mill smooth running.

Composition and Parameters:

| No. | Composition | Configuration |

| 1 | Uncoiler and Coil Car | 10T, cantilever |

| 2 | Shear and Welder | 3 x 650, argon welder |

| 3 | Spiral horizontal accumulator | 5m diameter,150m/min feeding |

| 4 | Two Heads tandem 4Hi Mill | DC 700KW x2, mechanic screw down |

| 5 | Recoiler | 350KW DC |

| 6 | Hydraulic system | 15KW, 600L tank |

| 7 | Thin oil lubricating system | 18KW 1000L tank |

| 8 | Emulsified coolant system | 1200-1500L/min flow |

| 9 | Electric control system | Siemens PLC and DC converters |

Tandem cold mill is a high technology equipment, it requires:

|