| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Waste Tyre Pyrolysis Plant |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-5Ton |

| Certification: | CE ISO |

| Place of Origin: | Xinxiang city, Henan,China |

| MOQ: | 1 set |

| Price: | USD35000-68000 per set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 220 sets per year |

| Delivery Time: | 15-25 work days |

| Packaging Details: | plastic flims for pyrolysis reactor , wooden boxes for small parts |

| Input raw material:: | waste tyre ,plastic ,PP PE PS,ABS,pmma |

| Output product: | Fuel oil , Carbon black ,gas |

| Heating fuel: | Wood /Coal /Gas /Oil |

| Function: | plastic pyrolysis plant china |

| Capacity: | 1-15ton per batch |

| Rotating speed: | 0.4 turn/minute |

| Type: | Batch type |

| Advantage: | environmental friendly |

Tire Pyrolysis Oil Plant In Uae 10 Ton Waste Tyre Pyrolysis Machine

Description

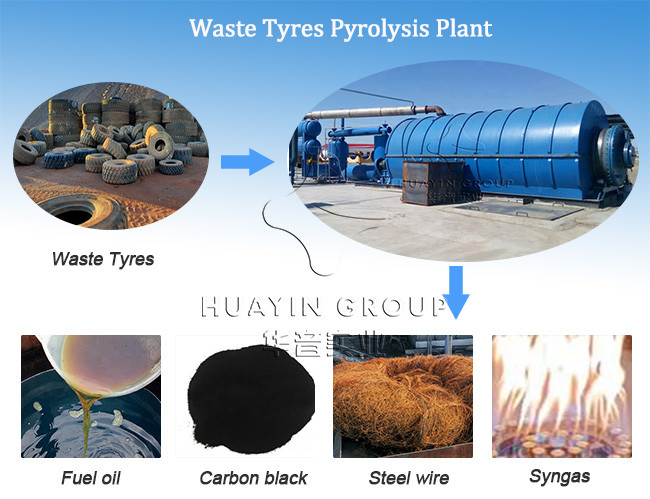

Pyrolysis can make up for the shortcomings of mechanical recycling, it doesn’t need the process of washing,and the tyre and plastic can be put into the pyrolysis reactor directly. The facility will convert mixed plastic and tires waste into hydrocarbon liquids ---pyrolysis oil , carbon black and steel wire.

Pyrolysis Applications

Pyrolysis plant can process various feedstocks like plastic pp , pe , ps , abs,tires and rubber waste for different purposes:

to recover energy - Waste-To-Energy plant (the pyrolysis oil can be used for power generator to produce electricity),

to reclaim materials (metals, activated carbon, catalyst, soil),

to dispose hazardous waste (medical waste,oily sludge waste).

Specification

| Item | Content | |

| Raw materials | Waste tyre/rubber | |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch | |

| HY2000*4000 | 3T/batch | |

| HY2200*6000 | 5 T/batch | |

| HY2600*6000 | 7 T/batch | |

| HY2600*6600 | 8 T/batch | |

| HY2800*6000 | 9 T/batch | |

| HY2800*6600 | 10 T/batch | |

| HY2800*8100 | 15 T/batch | |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 14mm/16mm/18mm | |

| The whole plant weight | 15-45 tons | |

| Land area | 300-400m2(L30-40m*W10m) | |

| Number of workers | 3-4 | |

| Processing time and power | 10-24 hours. Averagely 15KW/h | |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents | |

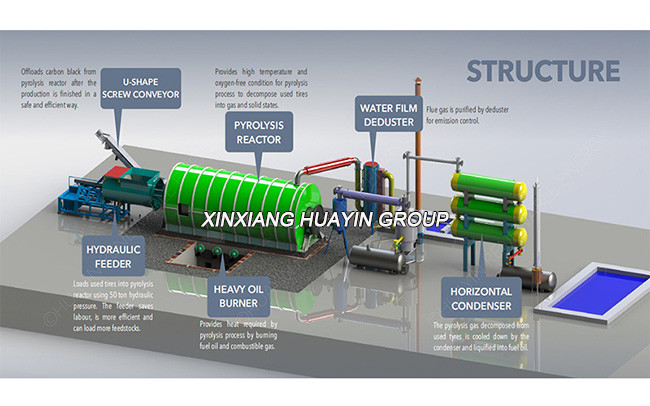

Operation Process

1: Feeding. Feed tires into reactor manually or with auto feeder;

2: Preheating. Waste tyres will be melted under high temperatures and oil gas comes out.

3: Oil-producing. Oil gas goes through the cooling system and is cooled down into liquid fuel oil; Some oil gas that can not be turned into liquid oil will go back to the heating furnace for second burning.

4: Cooling. After the oil processing is finished, leave the plant for cooling.

5: Carbon black discharging.

Function of the output product

1. Fuel oil (40-45%): Widely used as fuel oil in industries such as

steel and iron factories, ceramics or heavy oil generators, cement

factories, boiler heating, etc. Or being refined into non-standard

diesel for use in trucks, tractors, etc.

2. Carbon black(30%): Be pressed into pellets for use in industrial

heating;It can be ground and refined into different standards.

3. Steel wires(10%): Sold or reprocessed.

4. Combustible gas(10%-15%): Can be recycled and used during

production as fuel.

|